Voltage boost circuit

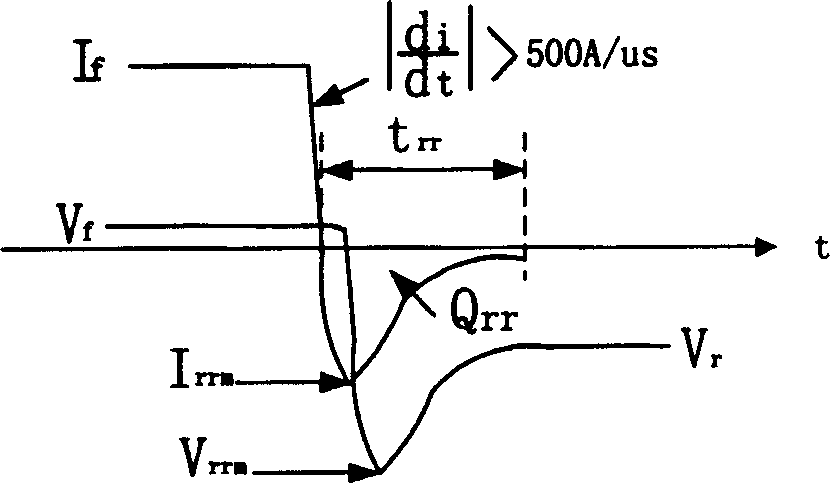

A booster circuit and loop technology, applied in the direction of conversion equipment without intermediate conversion to AC, can solve the problems of large loss, large reverse recovery current and reverse recovery time, and the switching frequency cannot be increased any more.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

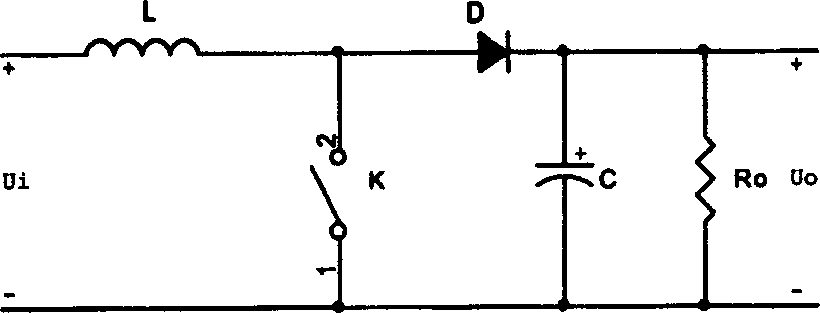

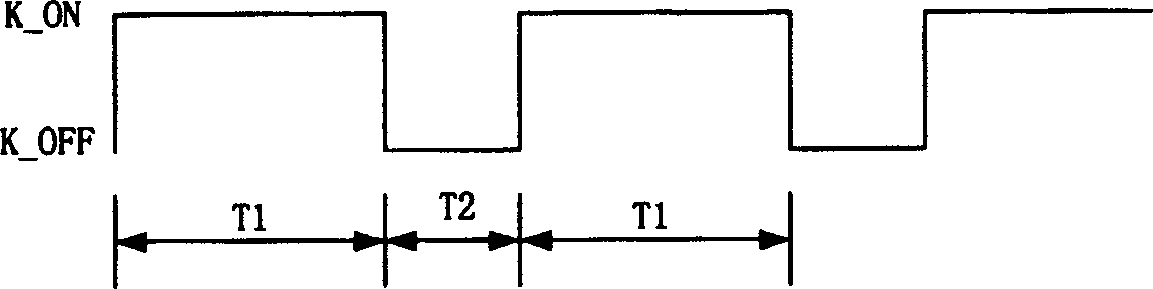

[0018] Using DC chopper boost circuit, the circuit see Figure 4 , which is characterized in that the DC chopper boost circuit is composed of at least two DC chopper boost circuits, and each DC chopper boost circuit is connected in parallel with a common capacitor, and alternately complements each other through dislocation to increase the switching frequency. Its specific circuit can be a chopper boost circuit with at least one common capacitor connected in parallel next to the common chopper boost circuit, and the switching frequency is increased through the dislocation and complementarity of the parallel circuits. Among them: the commutation inductor L1 and the diode D1 are connected in series on the power line, and a switch K1 is connected between the contact between the commutation inductor L1 and the diode D1 and the ground wire, and K1 is an IGBT...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com