Method of cleaning pipeline of lubricating oil, hydraulic oil and fuel oil

A technology for hydraulic oil and fuel pipes, which is applied in the fields of hydraulic oil, cleaning lubricating oil, and fuel pipe systems. It can solve the problems of prolonged oil flow time, manpower consumption, and material resources, and achieves improved production efficiency, safe operation, and convenient use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

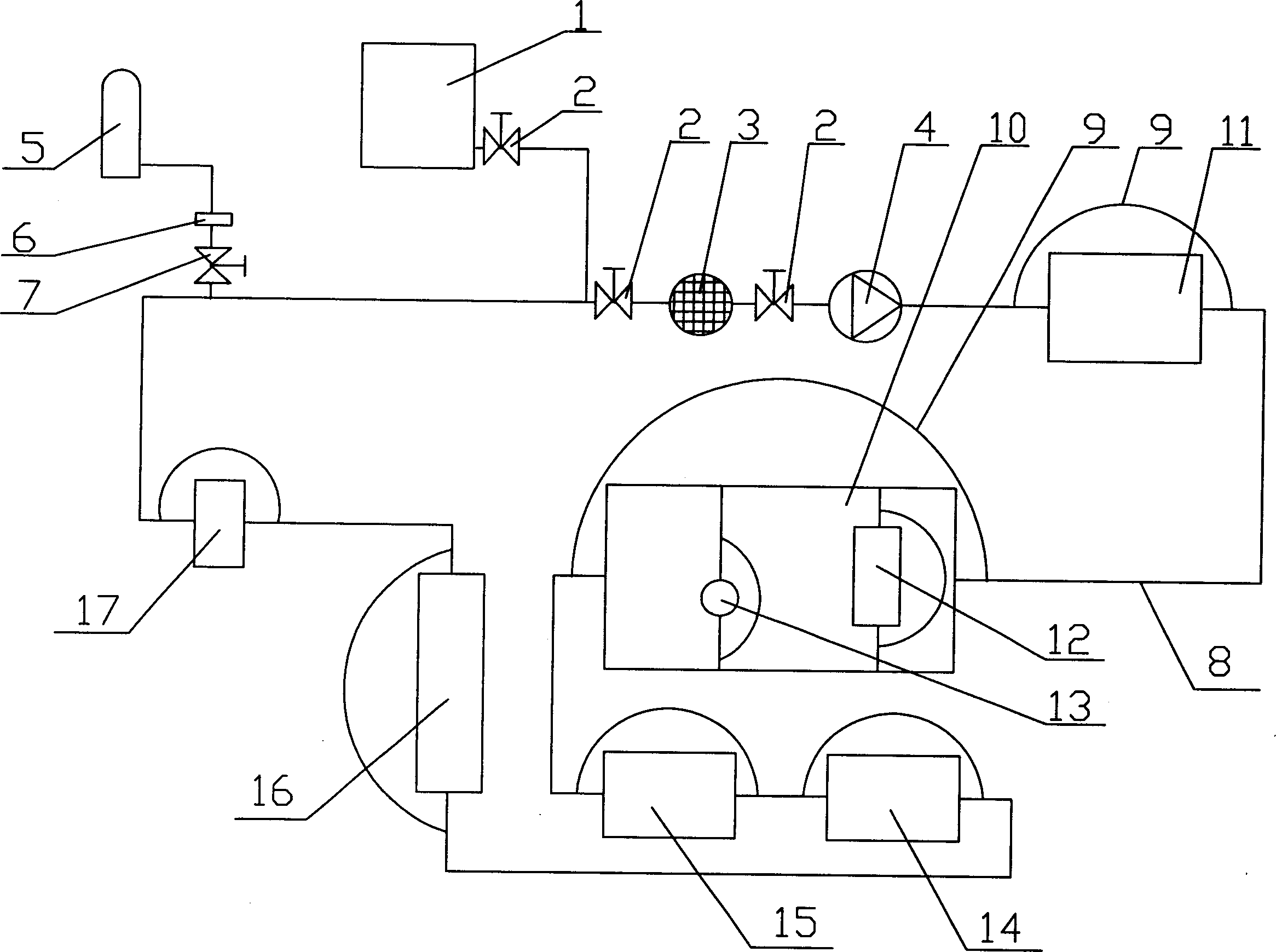

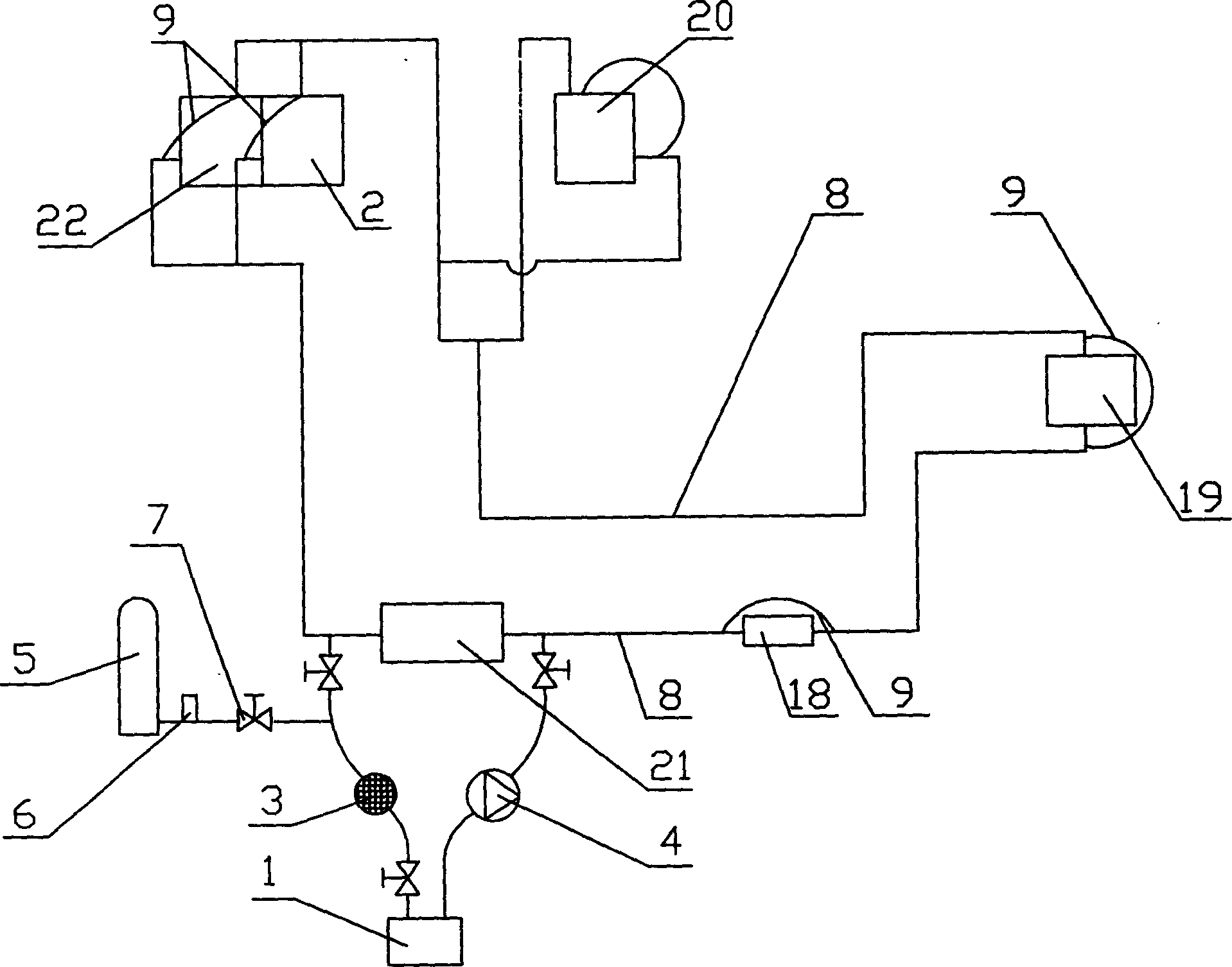

[0018] figure 1 Shown is one of the specific embodiments of the present invention, which is a schematic diagram of cleaning the lubricating oil piping system of the main engine, and the cleaning process is as follows:

[0019] a. Make temporary segmental cleaning pipelines: in the main engine 10, supercharger 11, cylinder oiler 12, indicator instrument 13, main engine oil circulation cabinet 14, intermediate bearing 15, lubricating oil cooler 16, main engine lubricating oil self-cleaning There are seven parts in the filter 17, and temporary segmental cleaning pipelines 9 are respectively set on the device, and then these temporary segmental cleaning pipelines 9 and the main pipeline 8 form the temporary cleaning pipeline of the lubricating oil piping system, and the temporary cleaning pipeline is formed by the main pipeline. 8. Cleaning liquid tank 1, composed of seven temporary segmental cleaning pipelines 9, valve 2, water pump 4, filter 3, compressed air bag 5, gas-water se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com