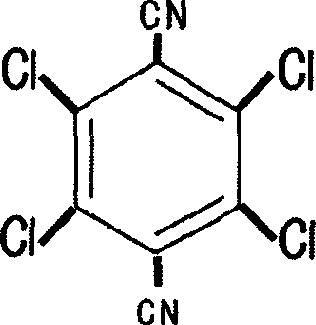

Industrial prepn process of tetrachloro terephthalonitrile

A technology of tetrachloroterephthalonitrile and tetrachloroterephthalic acid, applied in the dehydration preparation of carboxylic acid amide, organic chemistry, etc., to achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

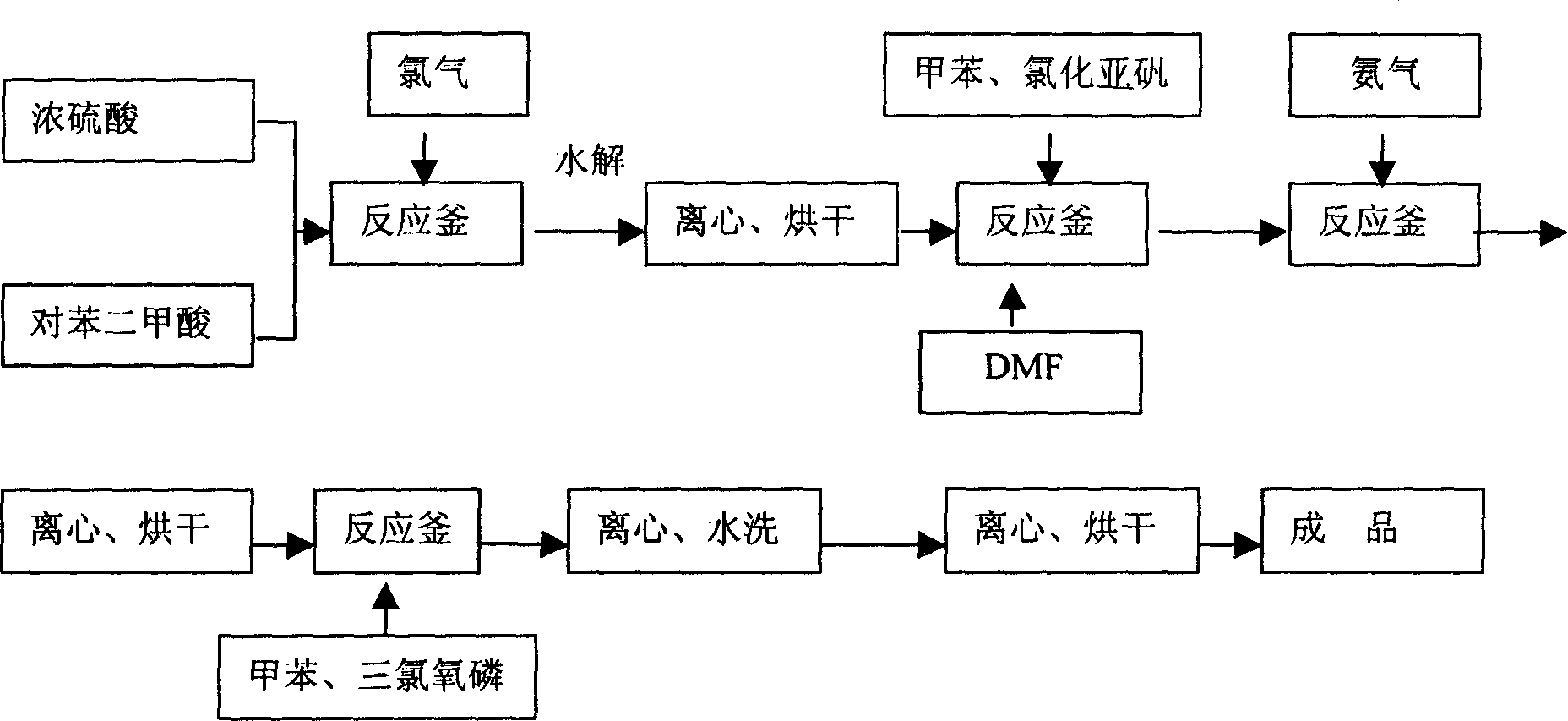

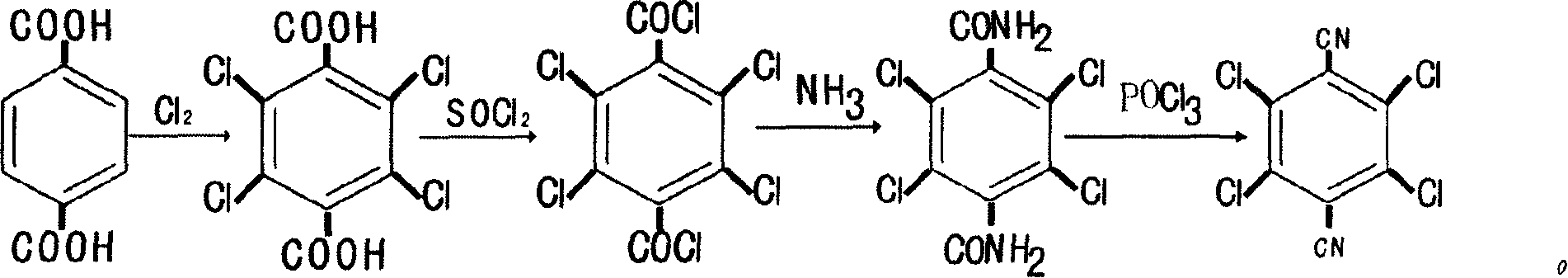

Method used

Image

Examples

Embodiment

[0021] Step 1: the preparation of tetrachloroterephthalic acid, in 1000ml flask, add 1mol terephthalic acid, 1g iodine, add the concentrated sulfuric acid that 500ml concentration is 40%~50%, pass into 4.5mol chlorine gas under the dark condition, The temperature is controlled between 80°C and 90°C, and a small amount of sulfuric acid is added in the later stage. When the temperature rises to 130°C, the ventilation speed should be slow and uniform. Slowly pour it into ice water, filter under ice water temperature to obtain a white solid, which is dried and crushed into powder, which is tetrachloroterephthalic acid;

[0022] Step 2: prepare tetrachloroterephthaloyl dichloride, put the tetrachloroterephthalic acid obtained in the previous step into a 2000ml flask, add 1200ml toluene and 2.2mol alumite chloride and 5mlDMF, slowly heat to reflux state, and keep warm for 6 Cool down after 1 hour, filter out impurities with absorbent cotton, remove the solvent, and cool down after r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com