Cold-hot box type heat transfer coefficient detecting instrument

A heat transfer coefficient, cold and hot box-type technology, applied in the direction of material thermal conductivity, etc., can solve the problems of poor measurement accuracy, defective insulation, and inability to quantitatively measure the thermal performance of enclosure structures, so as to improve reliability and facilitate Effects of data processing and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

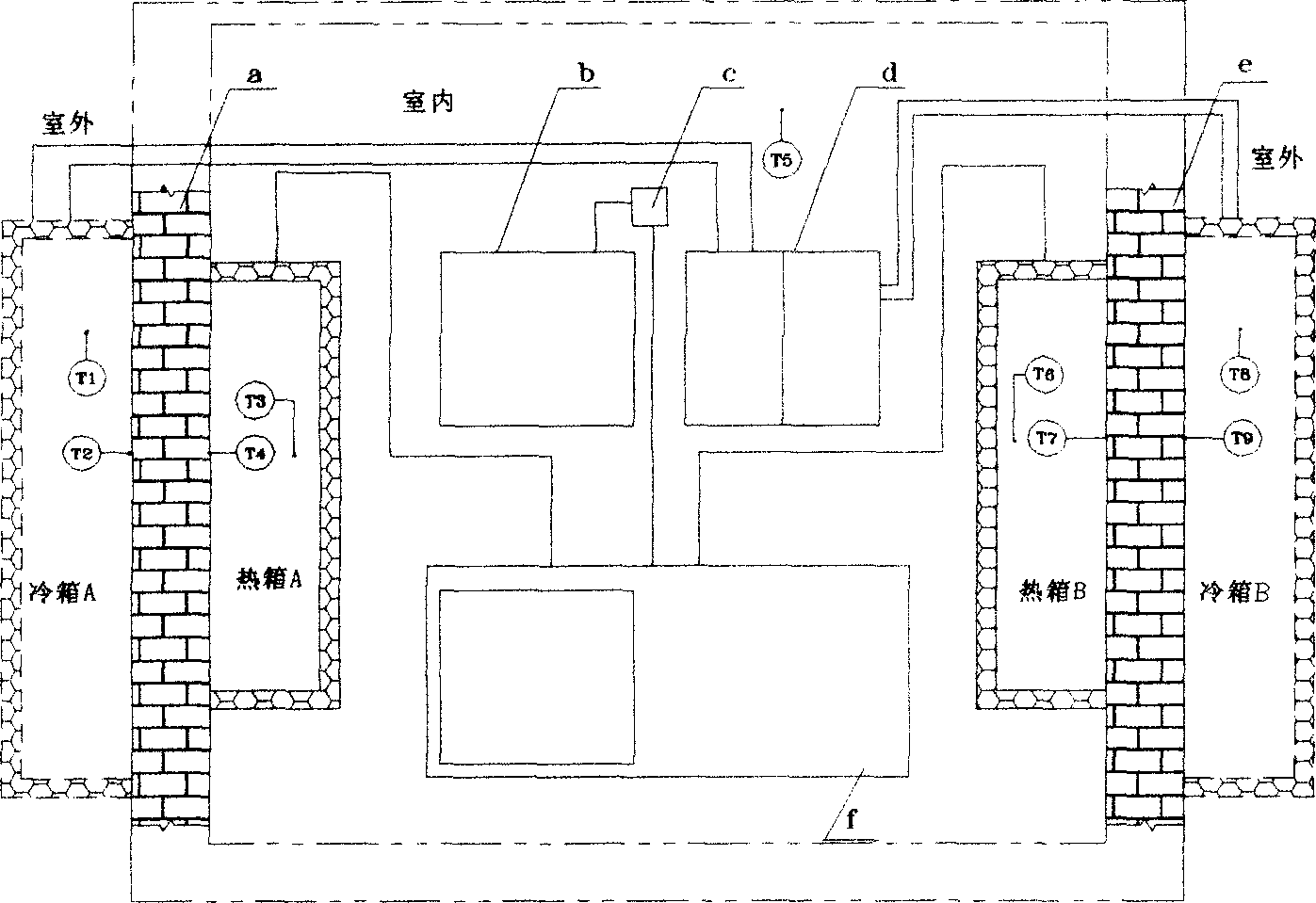

[0019] 1. Select the enclosure structure to be tested, measure the temperature distribution on the surface of the wall to be tested with an infrared thermometer, and select the part with uniform temperature distribution as the measured position. Fix the indoor wall surface temperature sensor. Close the open end of the heat box to the position to be tested. In order to achieve airtightness, a support rod should be used on the back of the heat box to hold it firmly. Confirm airtight.

[0020] 2. Fix the temperature sensor on the outdoor wall surface so that it is located in the center of the hot box and close to the wall surface. The end of the sensor is covered with tin foil to avoid direct sunlight; when the outdoor temperature is high, use a cold box to simulate the outdoor environmental conditions. The temperature inside the cold box is lower than the indoor control temperature; fix the outdoor air temperature sensor, leave the wall surface in the shadow of 10-20cm, and ins...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal resistance | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com