Crawler tractor

A tractor and crawler technology, applied in the fields of HST, braking mechanism and driving mechanism, can solve the problems of decreased cooling effect, difficult rotation of the output shaft, time-consuming assembly, etc., and achieve the effect of small braking capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

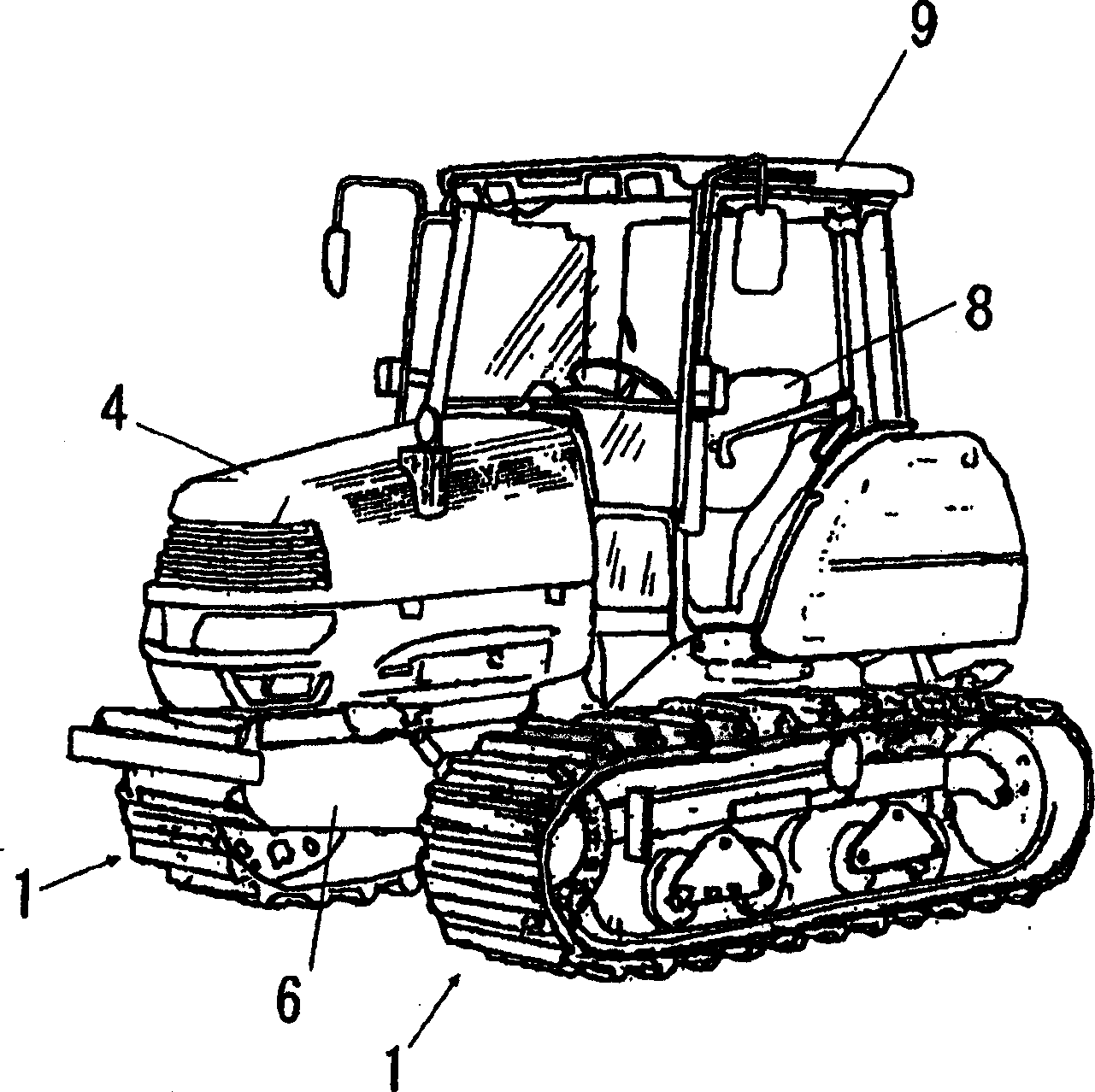

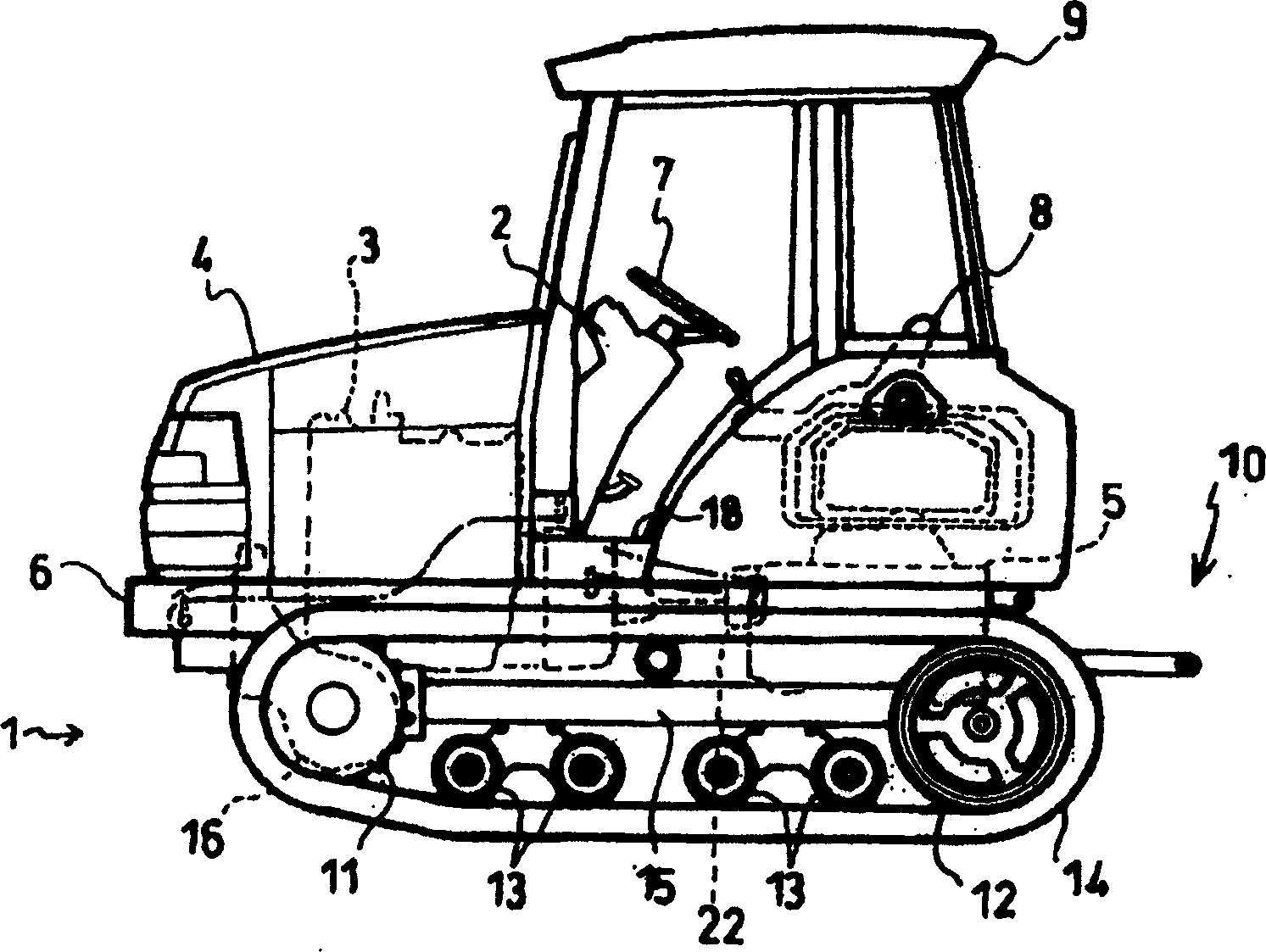

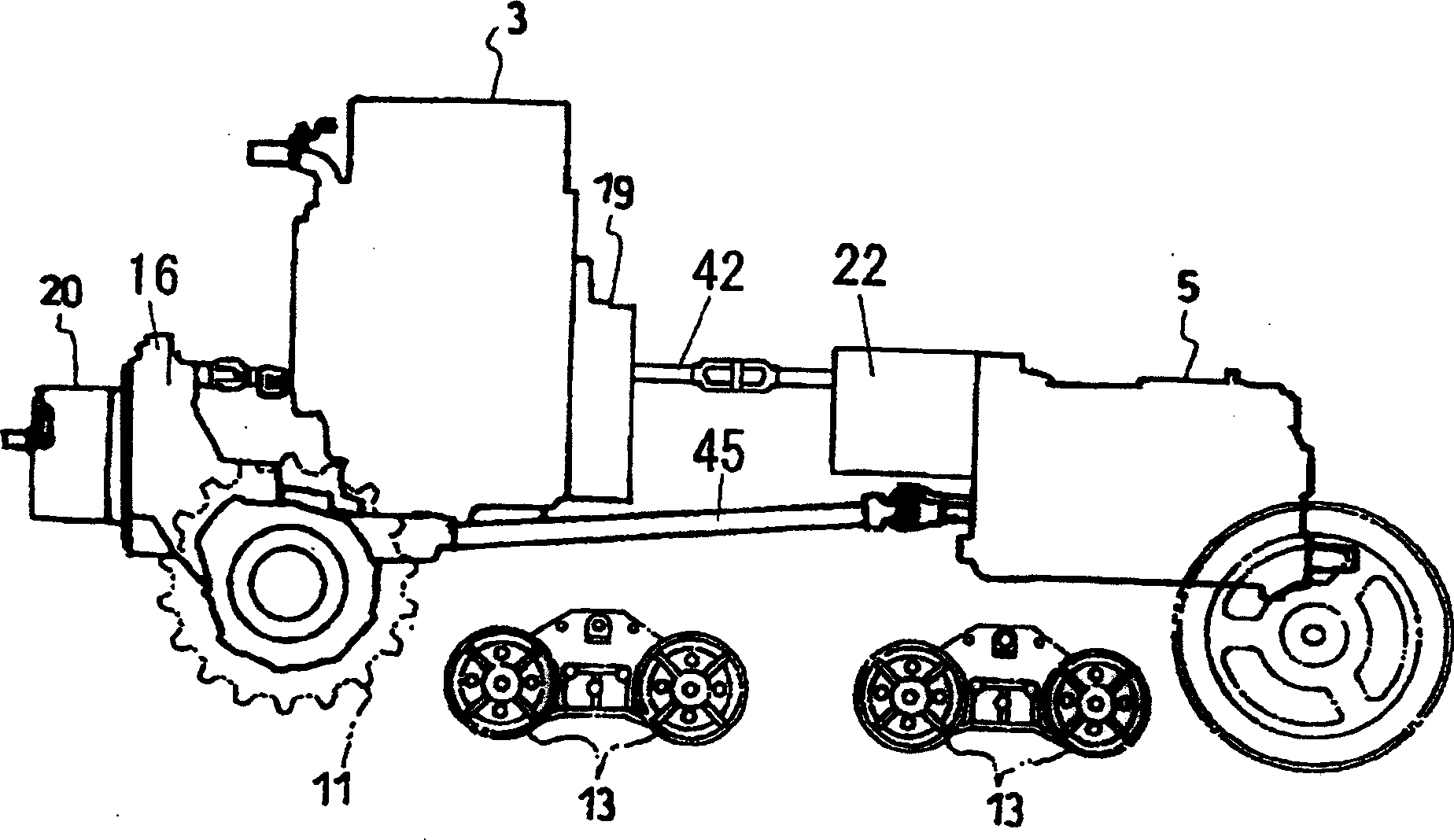

[0086] In order to explain the present invention in more detail, a description will be given based on the drawings.

[0087] First, the general structure of a crawler tractor as an embodiment of the steering mechanism of the present invention will be described.

[0088] Such as figure 1 with figure 2 As shown, the engine 3 is arranged above the front part of the crawler-type traveling mechanism 1, and the rear gearbox 5 is arranged above the rear part. The engine 3 is covered by a hood 4, and the engine 3 is fixed between the main frames 6 and 6 on the left and right lower sides.

[0089] A steering column 2 is provided at the rear of the hood 4, and a circular steering wheel 7 for steering operation is provided on the steering column 2. A seat 8 is provided behind the steering wheel 7, and a step 18 is provided below the steering column 2 and the seat 8 to constitute a driving part. The driver's part is covered by the driver's cab 9.

[0090] In addition, a three-point link typ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com