Hot pump system with variable capacity

A heat pump system and variable capacity technology, applied in heat pumps, lighting and heating equipment, refrigeration components, etc., can solve the problems of increased pipelines, damage, and increased manufacturing costs, and achieve the effect of simplifying the system, reducing manufacturing costs, and increasing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

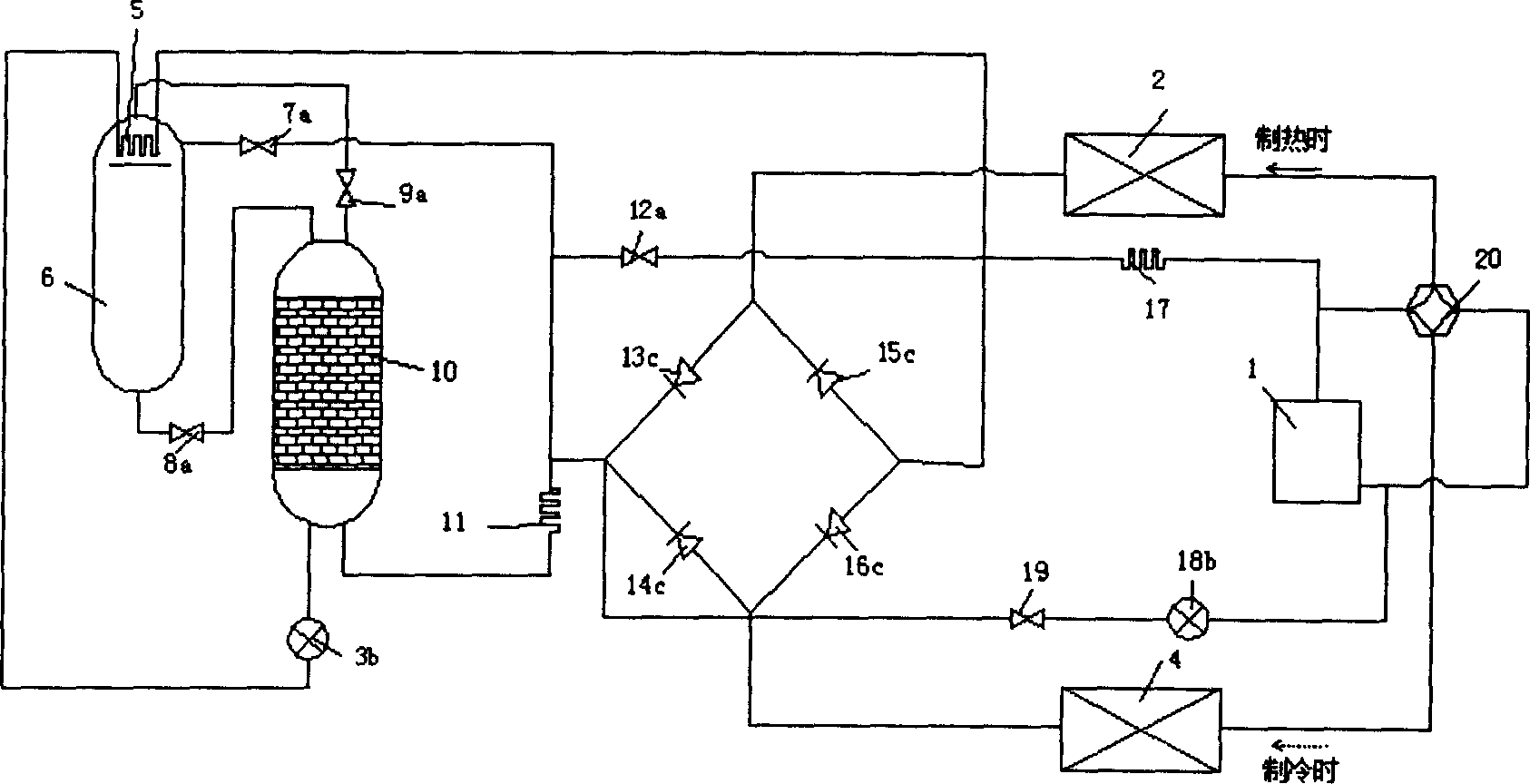

[0011] As shown in the drawings, the variable capacity heat pump system mainly includes a main system composed of an outdoor heat exchanger 4, a compressor 1, a first throttling device 3b and an indoor heat exchanger 2, and a rectification column 10, a liquid storage tank 6 , The separating device that cooler 5 forms. Among them, the main system is: the first pipeline branched from the exhaust port of compressor 1 is connected to one end of the first electromagnetic valve 12a through the first balance pressure member 17, and the second pipeline branched from the exhaust port of compressor 1 is connected to The first port of the four-way reversing valve 20 is connected to each other, and the second port of the four-way reversing valve 20 is connected to one end of the first one-way valve 13c and the second one-way valve 15c through the indoor heat exchanger 2 respectively. The first pipeline branched out from the valve 13c is connected to the other end of the first solenoid val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com