Inspection method and apparatus for mounted electronic components

A technology of electronic components and inspection methods, applied in the direction of electrical components, measuring devices, optical devices, etc., can solve the problems of not being able to take pictures, spending a lot of effort and time, and not being able to respond appropriately immediately, and achieve efficient installation and inspection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

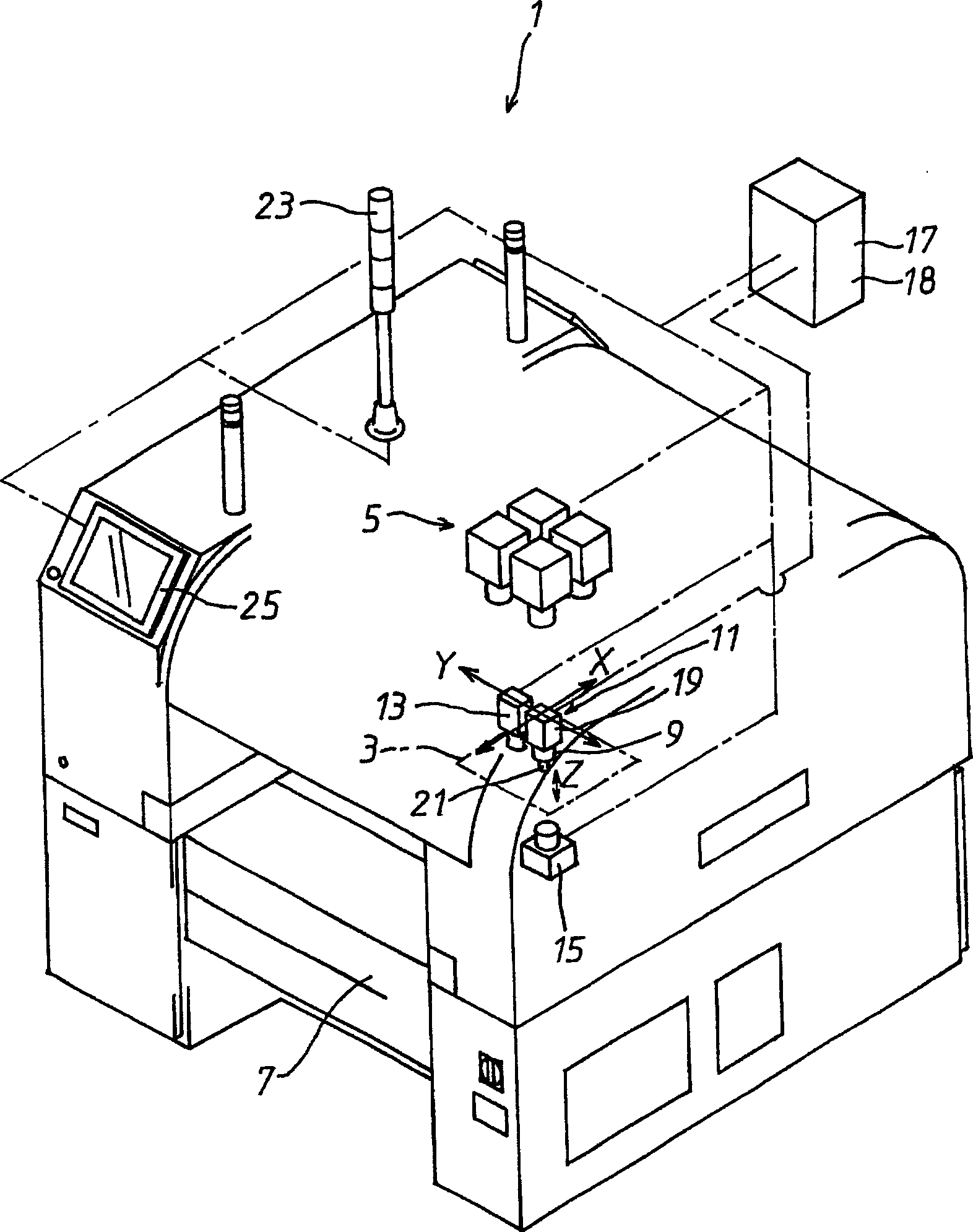

[0040] Hereinafter, a first embodiment of the inspection method and device of a mounted electronic component according to the present invention will be described based on the drawings. figure 1 It is a schematic perspective view showing a mounting machine 1 equipped with an inspection device for inspecting mounted electronic components 2 .

[0041] The mounting machine 1 to which this inspection device is installed includes: a camera device 5 consisting of a camera capable of taking in the entirety of the printed circuit board 3 carried in and positioned and placed in a predetermined position into the field of view at one time; Not shown in the drawing, it carries the printed circuit board 3 into the carrying position and positions it at a predetermined position; it is provided on a movable table (not shown) supported so as to be movable in the X and Y directions with respect to the base 7 The component transfer device 11 of the component mounting head 9 and the substrate reco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com