Method and device for limiting the current in a liquid metal current limiter

A liquid metal, current limiting device technology, applied in circuit breakers with excessive current, emergency protection devices, high voltage/high current switches, etc., can solve the problems of arc oxidation and expensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

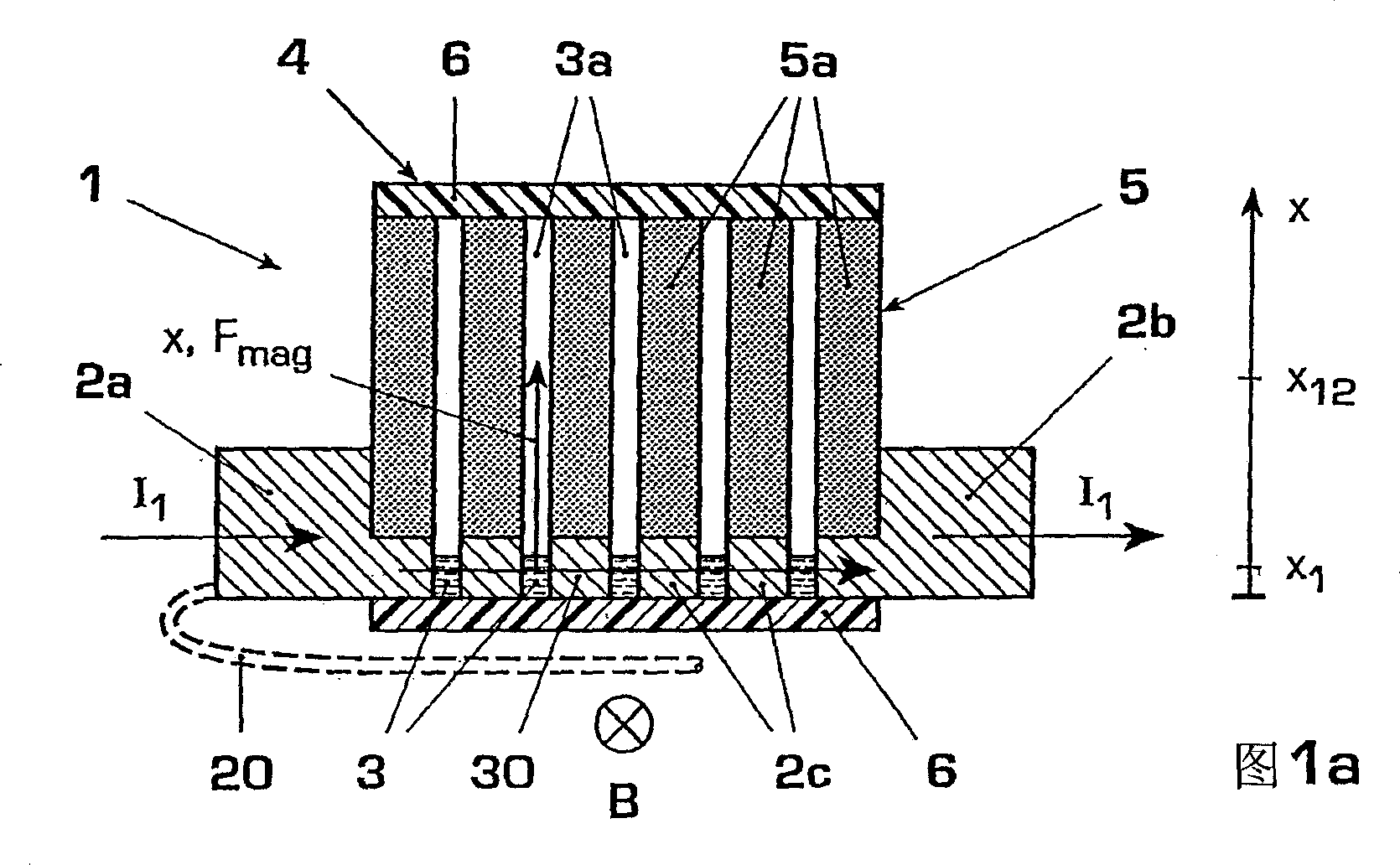

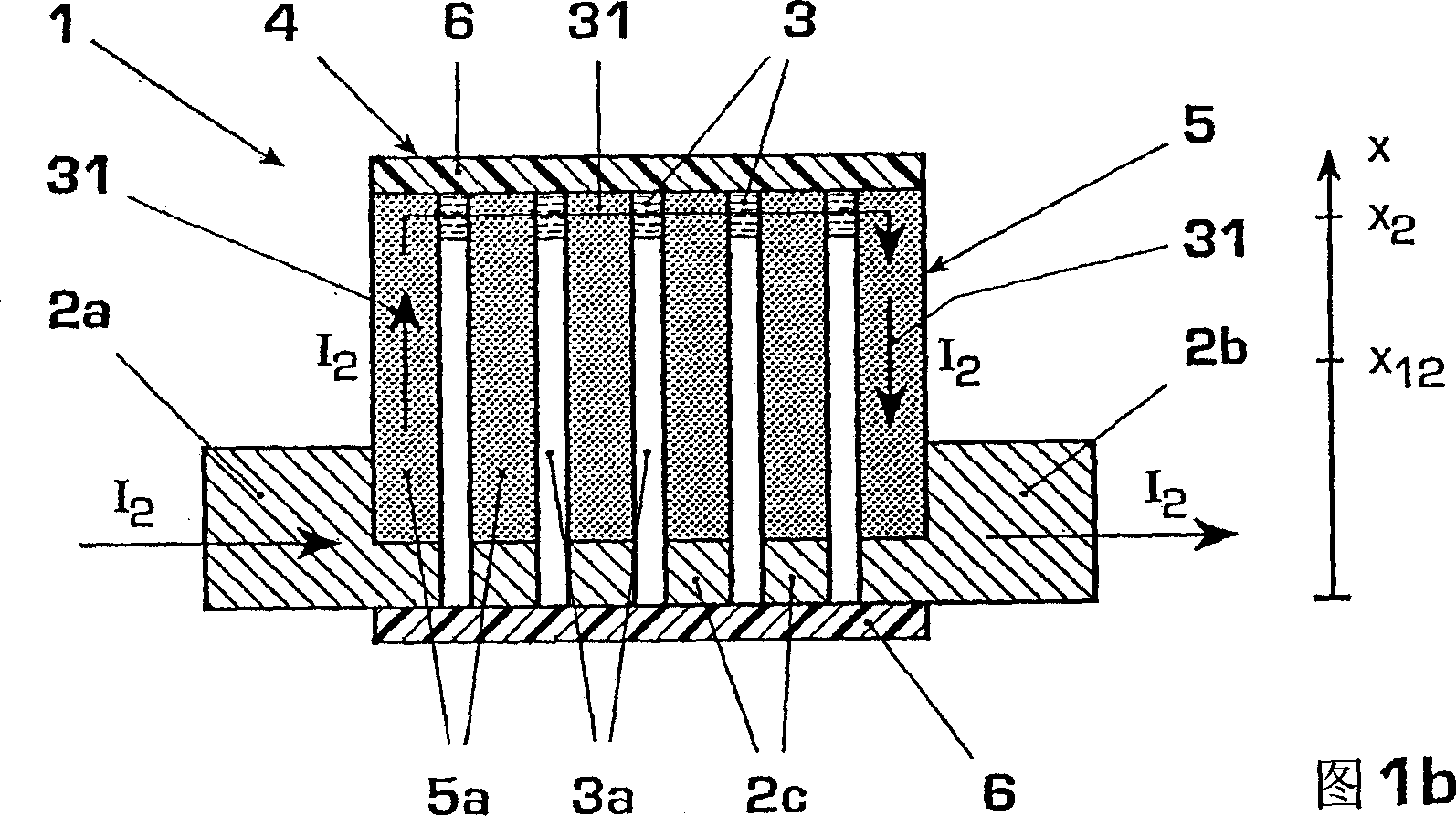

[0023] Figures 1a, 1b show an embodiment of a flow restrictor 1 of the liquid metal type. The current limiter 1 comprises solid metal electrodes 2a, 2b and an intermediate electrode 2c for a current lead 20 and a container 4 for liquid metal 3 . The container 4 has a bottom 6 of insulating material and a cover 6, between which an electrical impedance device 5 with at least one channel 3a for the liquid metal 3 is arranged. Above the liquid metal body 3 , for example, a protective gas, an insulating liquid (with escape volume not shown in the figure) or a vacuum can be provided.

[0024] In the first working state (see Figure 1a), the working current or rated current I 1 , on a rated current path 30 from the input electrode 2a via the liquid metal 3 and optionally via the intermediate electrode 2c to the output electrode 2b. In this case, the liquid metal 3 is in the first position X 1 , the solid electrodes 2a, 2b, 2c are at least partially wetted and bridge the channel 3a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com