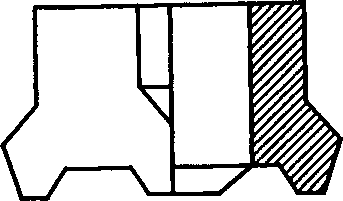

Process for forming external welding leg square nut by multiple work position cold headers from coiled round wire

A multi-station, cold heading machine technology, applied in the field of metal forging processing, can solve the problems of low product precision, increased handling time, unstable quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

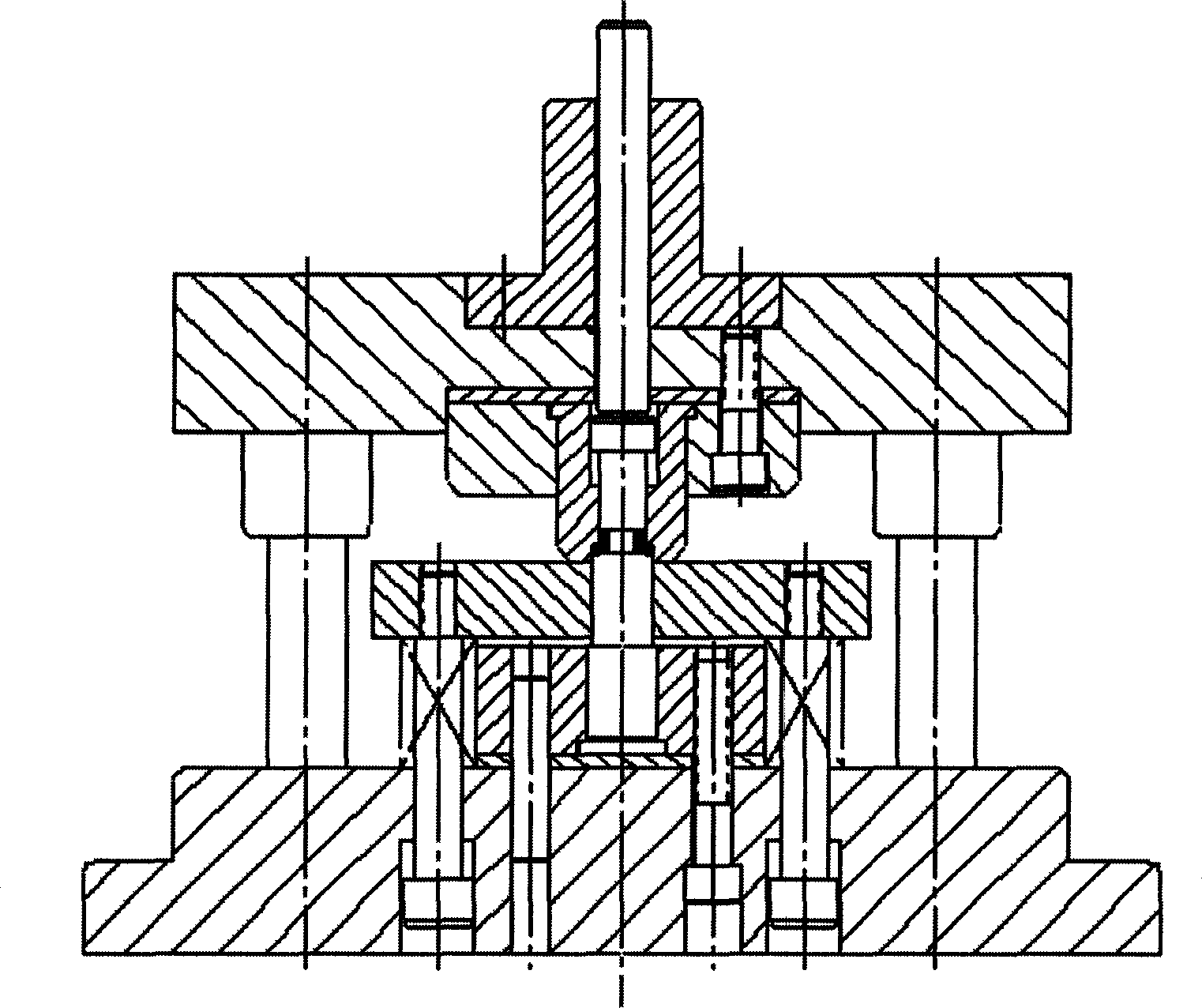

Image

Examples

Embodiment Construction

[0026] Please refer to figure 2 , when the coiled wire used in the present invention is cut, shaped, pre-formed, outer solder leg formed, and punched, there are operations such as automatic feeding and automatic pinching. Before explaining the manufacturing process of the present invention, the automatic feeding, automatic The operation of the pinch device and so on will be explained.

[0027] A. Automatic feeding:

[0028] The automatic feeding device of cold heading machine mainly includes: cam, feeding rocker, ratchet, pawl and feeding wheel and other components. The cam drives the feed rocker to make the ratchet actuate the ratchet to rotate an angle θ. When the ratchet rotates θ, the feeding wheel will synchronously rotate the angle θ to feed the material, and the feeding wheel will be divided into 2π / θ equal parts to feed the material. The effective working diameter of the wheel is D, and the feeding length each time is πD÷(2π / θ)=Dθ / 2.

[0029] Assuming that the volu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com