Eye protector for laser processing equipment

A technology of laser processing machine and pulse signal, which is applied in the direction of engineering safety devices, mechanical equipment, etc., can solve the problems of easy damage to eyes, glare and other problems, and achieve the effect of protecting eyes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

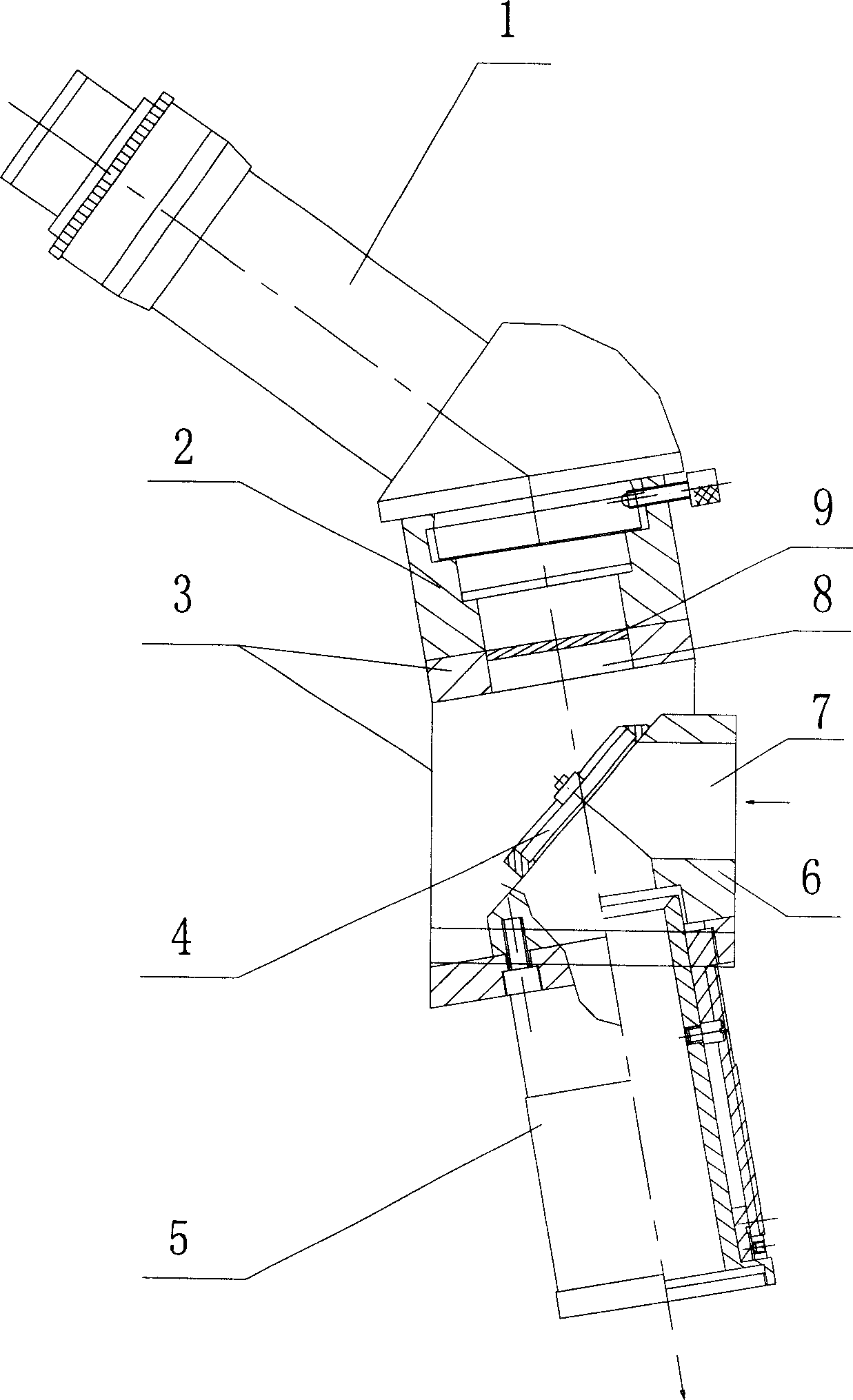

[0010] Such as figure 1 As shown, an eye protection device for a laser processing machine is mainly composed of a liquid crystal glass screen 9, a wire 10, and a pulse signal processing circuit 11. The liquid crystal glass screen 9 is connected to the output interface of the pulse signal processing circuit 11 by a wire 10 , the input interface of the pulse signal processing circuit is connected with the output end pulse signal of the laser power supply.

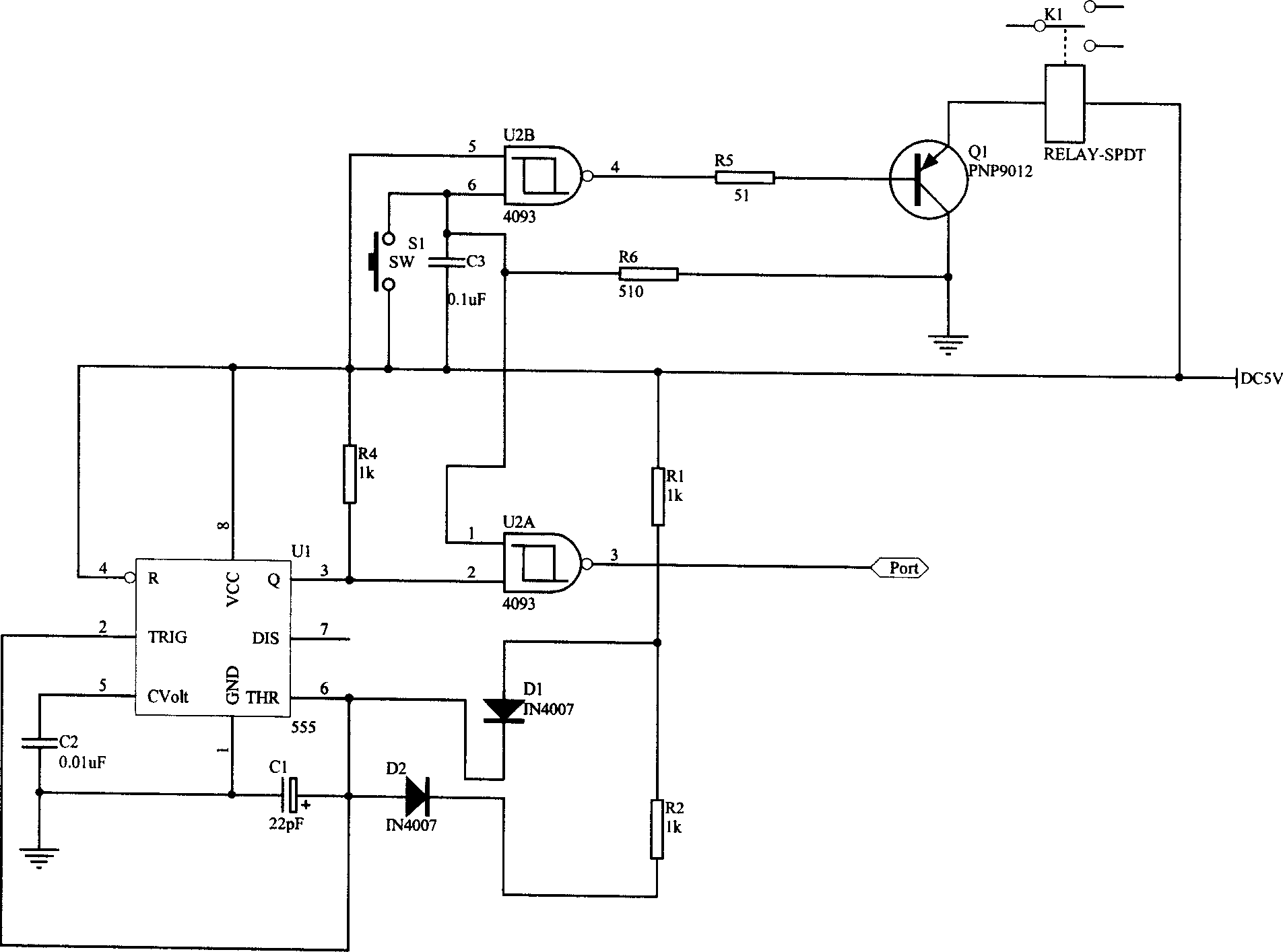

[0011] Such as figure 2 As shown, the pulse signal processing circuit is mainly composed of 555 timer, 4093 Schmitt trigger, triode Q 1 , Diode D 1 , Diode D 2 , capacitance C 1 , capacitance C 2 , capacitance C 3 , resistance R 1 , resistance R 2 , resistance R 4 , resistance R 5 , resistance R 6 , switch K 1 Composition, the 2 pins of the 555 timer are connected with the 6 pins of the 555 timer and the diode D 1 The cathode of the diode D 2 The positive pole of the 555 timer is connected to the capacitor C 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com