Ultra-magnetostriction window-shaped elliptic composite vibration transducer and transduction method

A technology of giant magnetostriction and giant magnetostrictive rod is applied in the direction of fluid using vibration, which can solve the problems of low output power and complex structure of the transducer, reduce cutting force, improve processing quality, and simple device structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

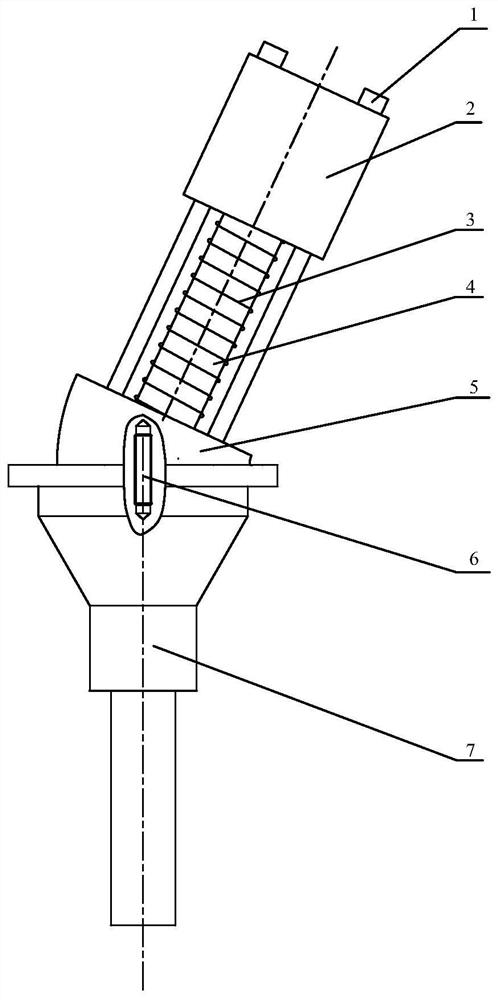

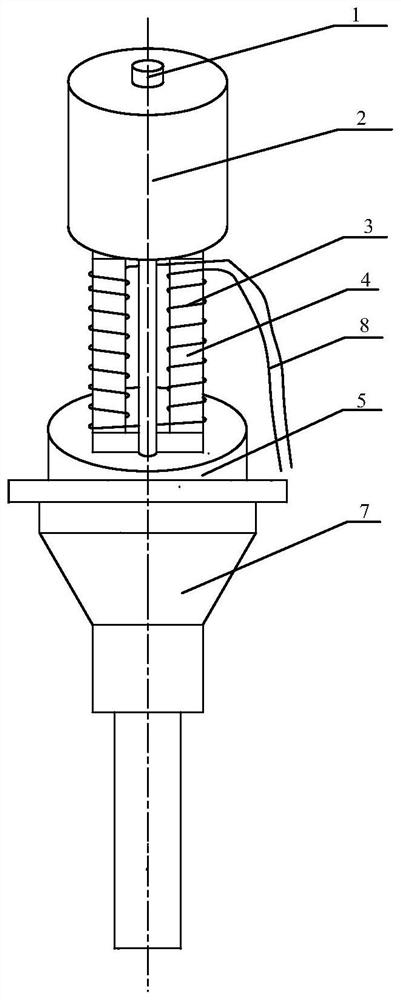

[0037] see figure 1 as well as figure 2 , the giant magnetostrictive window-shaped elliptical composite vibration transducer provided in this embodiment includes a rear cover 2, a vibration telescopic unit 4, a wedge 5 and a horn 7 arranged in sequence from top to bottom; the rear cover 2 , the vibration expansion unit 4 and the wedge block 5 are fixed, the wedge block 5 is fixedly connected with the horn 7, and forms elliptical compound vibration on the output end of the horn 7, and the overall structure is simple.

[0038] In this embodiment, the rear cover plate 2 is a cylinder, the vibration telescopic unit 4 is a window-shaped structure, and the horn 7 includes a circular platform section, a large cylindrical section and a small cylindrical section connected sequentially from top to bottom; the large circular end surface of the circular platform section A flange is arranged on the top, and the flange is connected with the wedge block 5; the small round end face of the c...

Embodiment 2

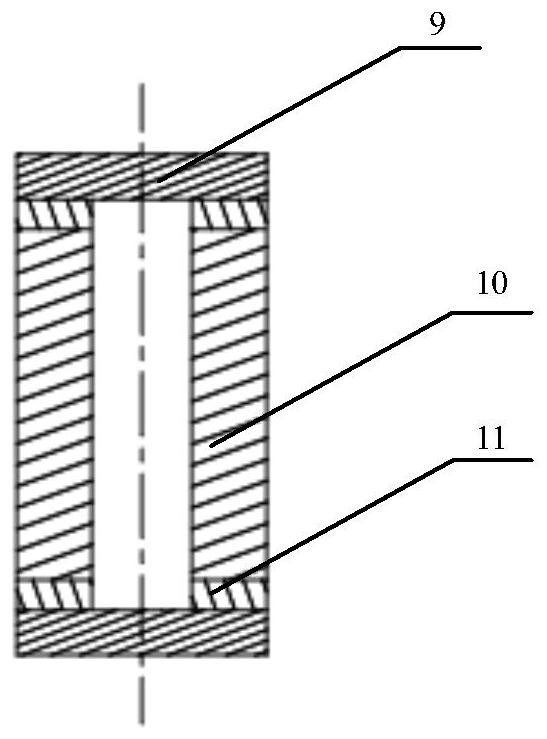

[0046] On the basis of Embodiment 1, the materials of the rear cover plate 2 and the horn 7 are all stainless steel; the material of the wedge block 5 is aluminum alloy; the material of the giant magnetostrictive rod 10 is Terfenol-D; the material of the magnetizer 9 It is electrical pure iron; the material of the permanent magnet 11 is NdFeB.

[0047] The diameter of the back cover 2 is 36mm, and the length is 36.5mm; the specification of the giant magnetostrictive rod 10 is 15mm×7.5mm×35mm; the material of the magnetizer 9 is electrical pure iron; the specification of the permanent magnet 11 is 15mm×7.5mm ×3mm; the diameter of the large flange of the horn 7 is 60mm, and the length is 5mm; The diameter is 15mm and the length is 51mm.

[0048] Further, the included angle (angle θ) between the two slopes of the wedge block 8 and the diameter of the wedge block 8 affect the vibration frequency, lateral displacement, longitudinal displacement and phase difference of the transduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com