Transparent gel self-adhesive agent, transparent gel self-adhesive sheet, optical filter for display

An adhesive and filter technology, applied in the direction of adhesives, film/sheet adhesives, chemical instruments and methods, etc., to achieve excellent buffering properties, migration prevention, and durability improvement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

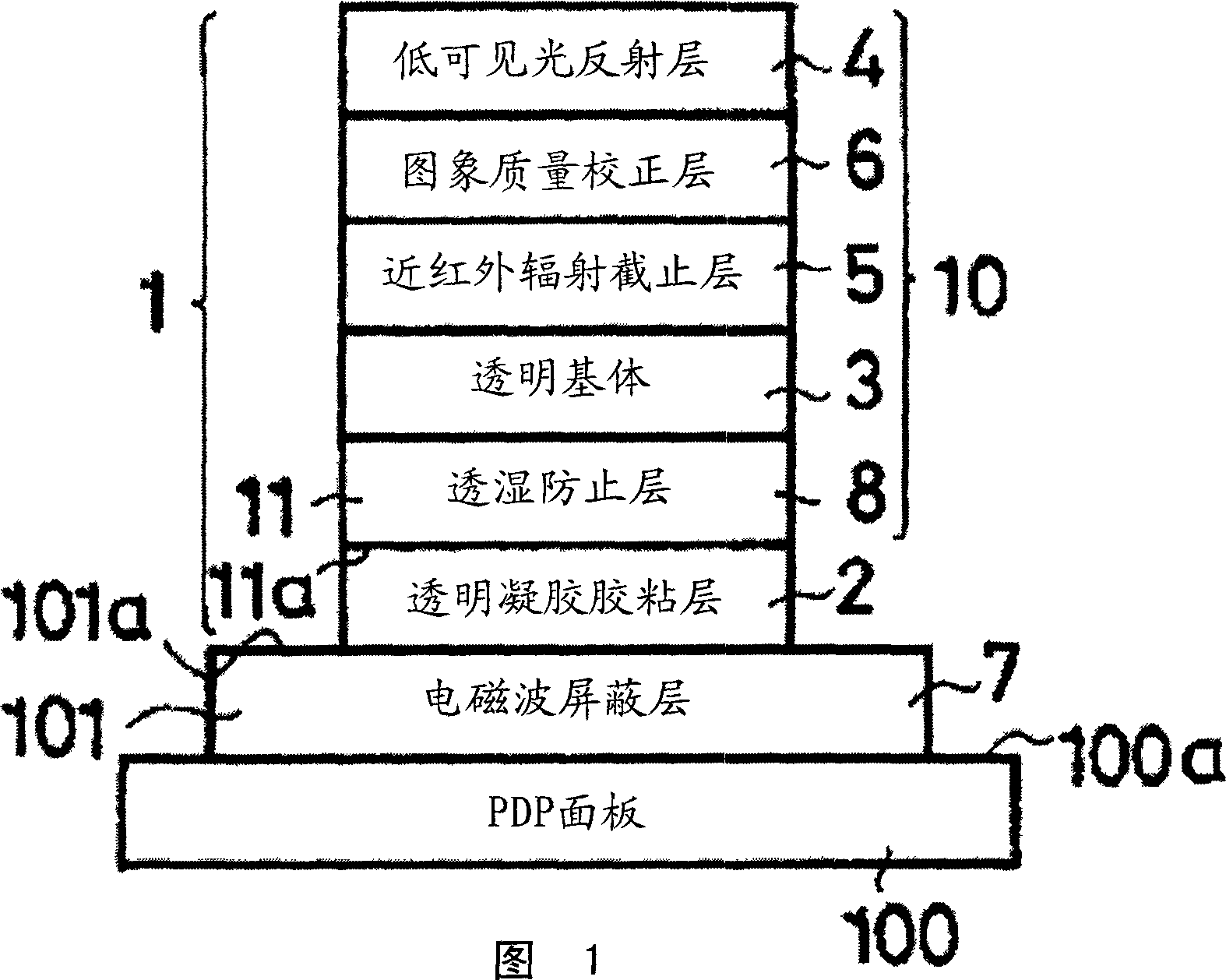

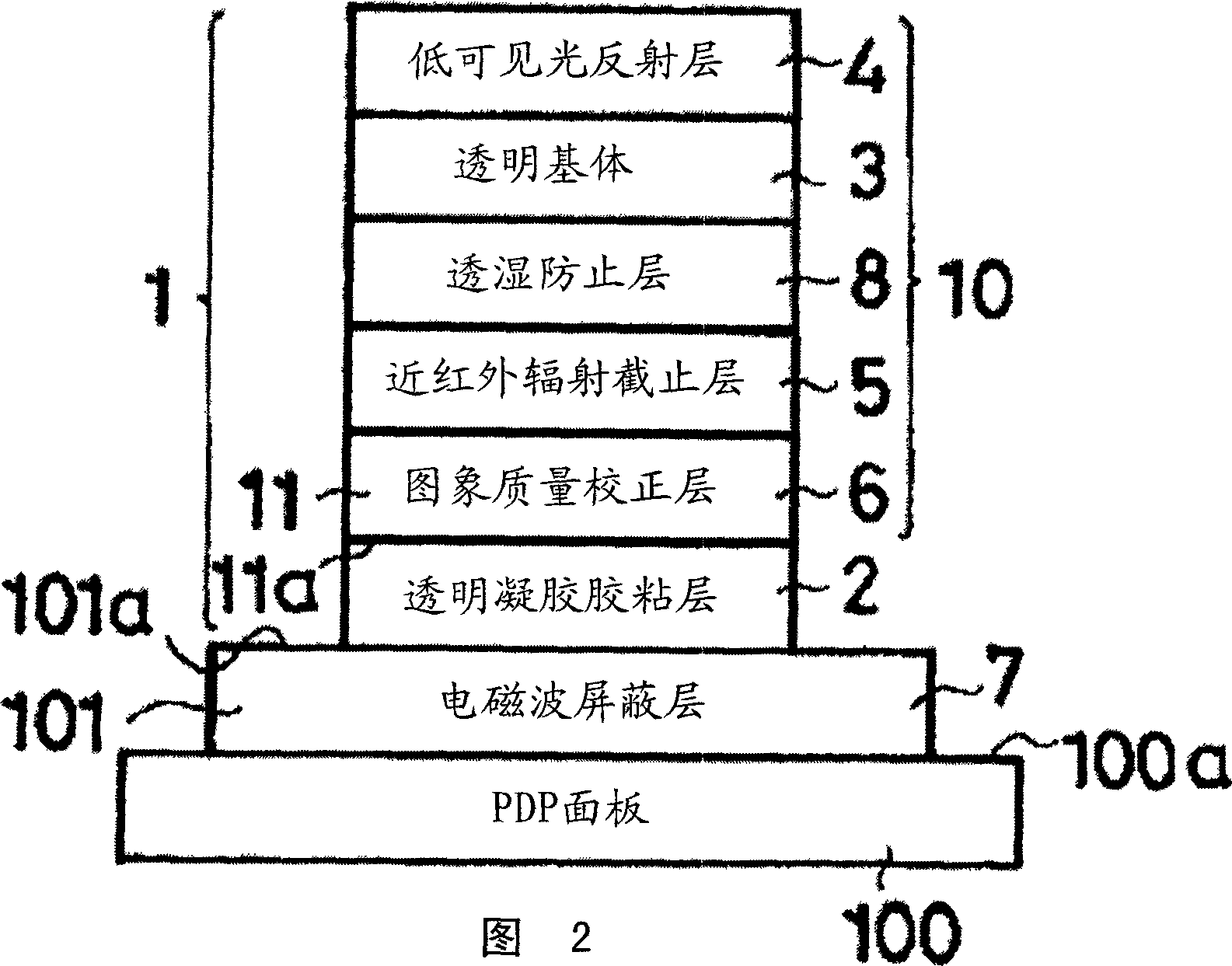

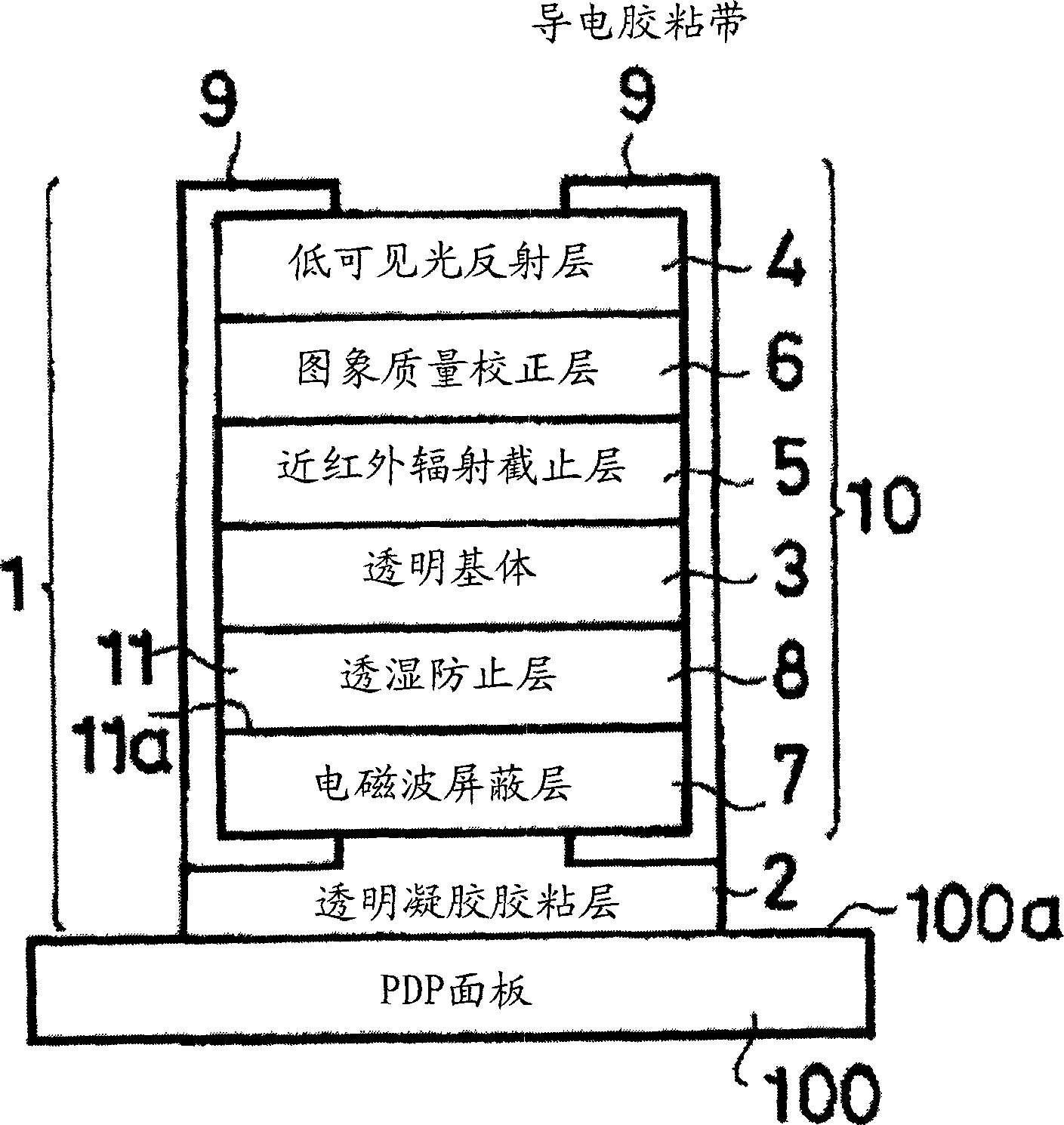

Image

Examples

Embodiment 1

[0196] In the acrylate copolymer of 100 weight parts, add the trade name that 0.3 weight part Ciba SpecialtyChemicals produces is called Irgacure 500 as photoinitiator and the trade name that 0.3 weight part Osaka Organic Chemical Industry produces is called Viscoat V260 (1,9-nonyl diacrylate) glycol ester) as a crosslinking monomer to obtain a UV crosslinking composition. The composition of the acrylate copolymer used is 78.4% by weight of n-butyl acrylate, 19.6% by weight of 2-ethylhexyl acrylate and 2.0% by weight of acrylic acid that have been copolymerized. The viscosity is 250,000 (mPa.s).

[0197] In the above-mentioned ultraviolet light crosslinking composition, the plasticizer diisodecyl phthalate (DIDP) and 2% by weight of Nippon Aerosil are mixed with 20% by weight of the superfine silica particles produced by Nippon Aerosil, and the primary average The particle diameter was 7 nm, which was melt-stirred to obtain a sol composition.

[0198] The sol composition is sa...

Embodiment 2

[0204] To 100 parts by weight of the acrylate copolymer used in Example 1, 2.0 parts by weight of a photoinitiator "Irgacure 500" and 2.0 parts by weight of a crosslinking monomer "Viscoat V260" were added to obtain an ultraviolet light crosslinking composition.

[0205] In this ultraviolet light crosslinking composition, the plasticizer diisodecyl phthalate (DIDP) of 60% by weight and 10% by weight of “Aerosil50” silica ultrafine particles with a primary average particle diameter of 30nm are mixed. Melt stirring is performed to obtain a sol composition.

[0206] Sandwich the above-mentioned sol composition between peelable PET with a thickness of 75 μm and 100 μm, heat-melt and form it into a sheet with a thickness of 0.5 mm, and use a high-pressure mercury lamp to radiate 4000 mJ / cm on each side from the front and rear sides through the peelable PET 2 The cumulative amount of light, a transparent gel adhesive sheet was obtained. Using the transparent gel adhesive sheet obta...

Embodiment 3

[0208] 20% by weight of plasticizer diisodecyl phthalate (DIDP) and 2% by weight of Aerosil 50 were mixed into the UV crosslinking composition obtained in Example 1, and melted and stirred to obtain a sol combination , and a transparent gel adhesive sheet and a laminate were obtained by a method similar to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com