Iron sintered component and producing method and sintered mechanical parts

A manufacturing method, iron-based technology, applied in the field of iron-based sintered parts and its manufacture, and sintered mechanical parts, can solve the problems of reduced strength, inability to impart strength and machinability separately, and achieve the effect of strength and machinability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0059] (Effect of copper immersion on machinability and strength)

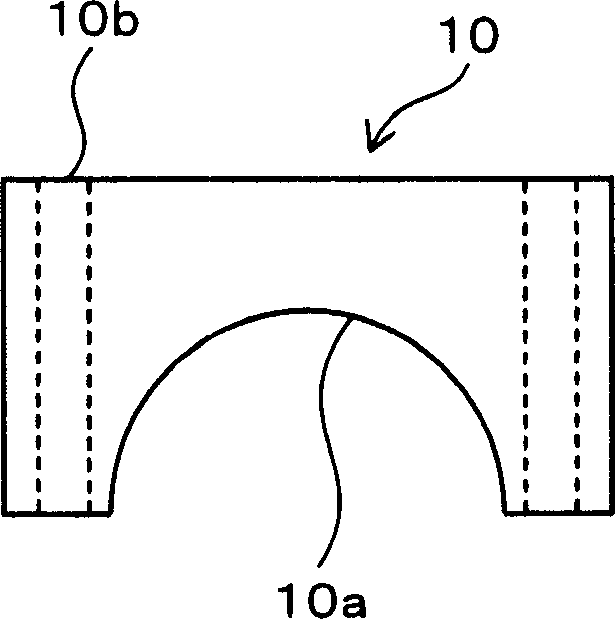

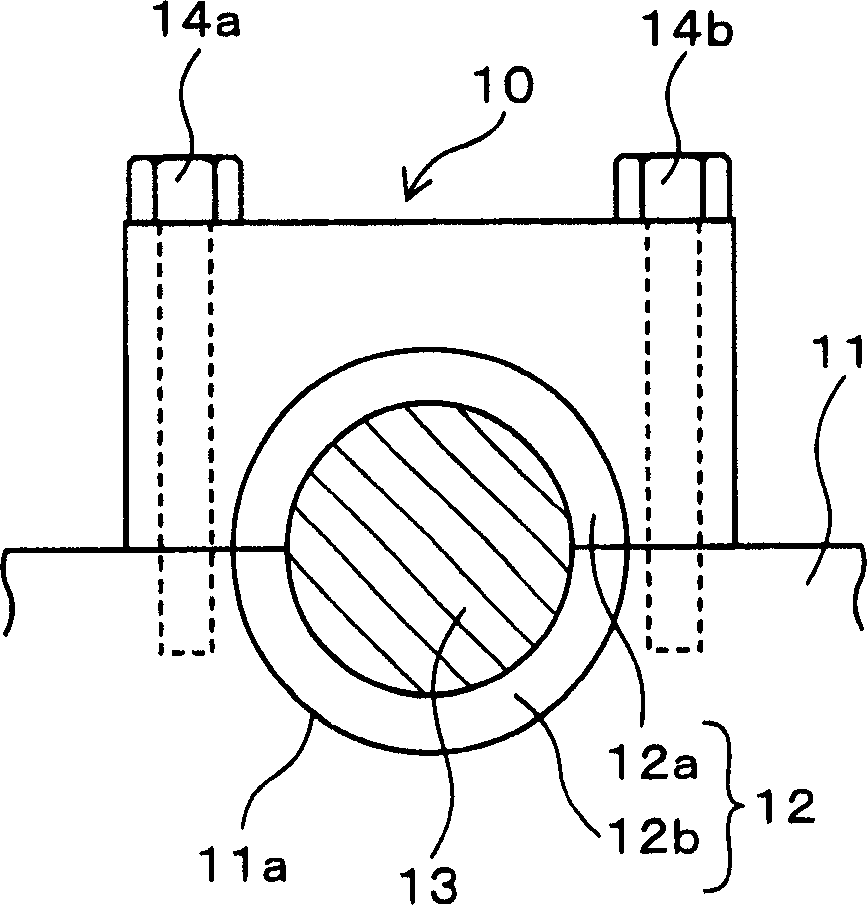

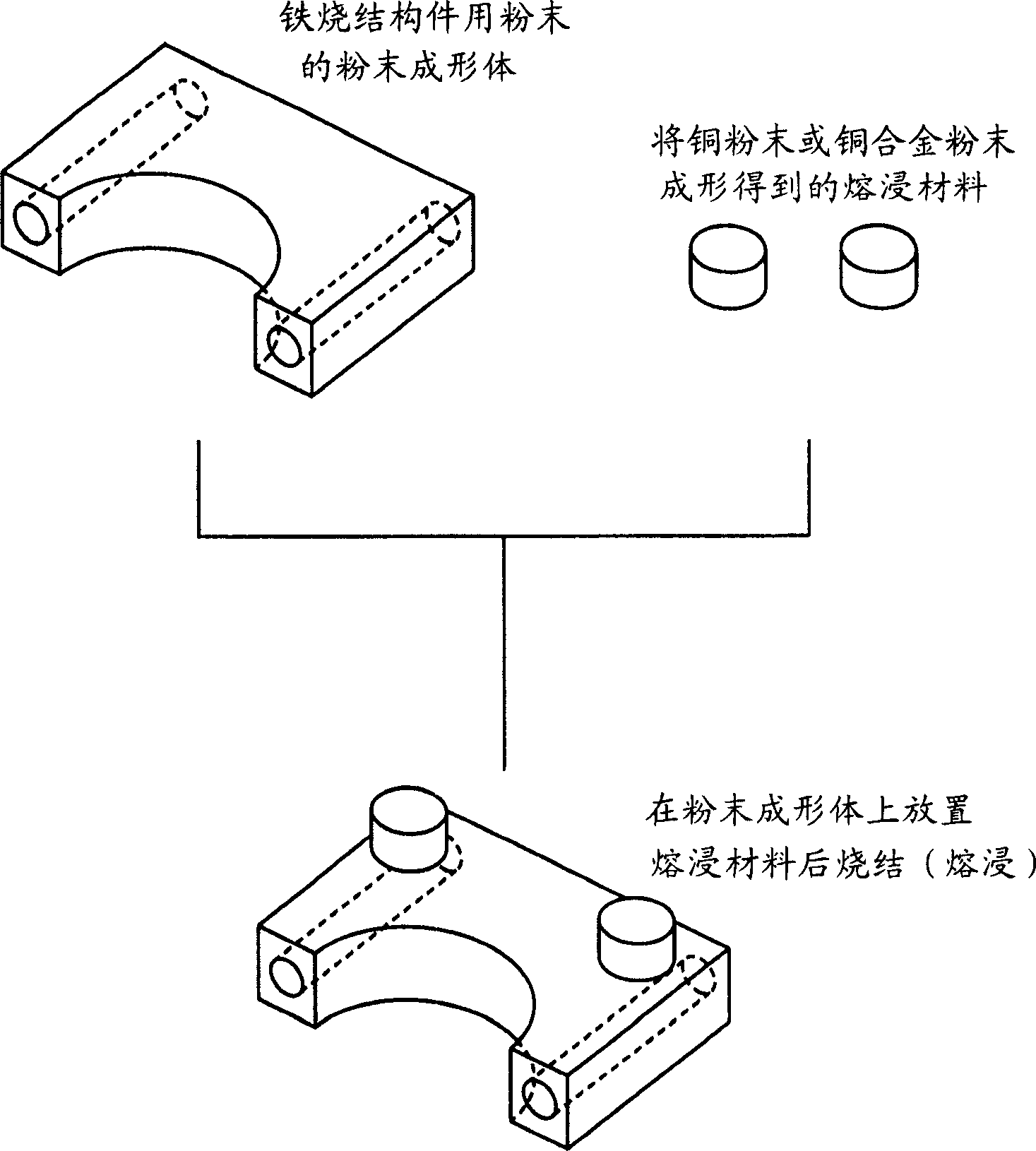

[0060] As the raw material powder, prepare Cu: 3.0% by mass, C: 1.0% by mass, B 2 o 3 : 0.7% by mass of powder for iron-based sintered structural parts with the balance being Fe and unavoidable impurities, mixed with a V-type mixer for 30 minutes, and compacted to a density of 6.7g / cm 3 , get as image 3 A powder compact in the shape of the bearing cap shown. In addition, pure copper powder is compacted to obtain such as image 3 2 dipping materials shown.

[0061] Then, after presintering the above-mentioned powder molded body at 690° C. in a reducing environment, in order to impregnate the part of the presintered body in contact with the bolt support surface with an impregnation material, image 3 In the form shown, the immersion material is placed on the pre-sintered body, and sintering (immersion) is performed at 1130° C. in a reducing atmosphere in this state.

[0062] Figure 4 is a photo of the struc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com