Air corrosion monitoring system of area distributing drainage building

A technology for drainage structures and monitoring systems, applied in the field of regional distributed drainage structure cavitation monitoring systems, can solve the problems of high vibration and noise, "low signal-to-noise ratio, and high flow rate, and achieve convenient construction and operation management. , the effect of high diagnostic accuracy and wide monitoring range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

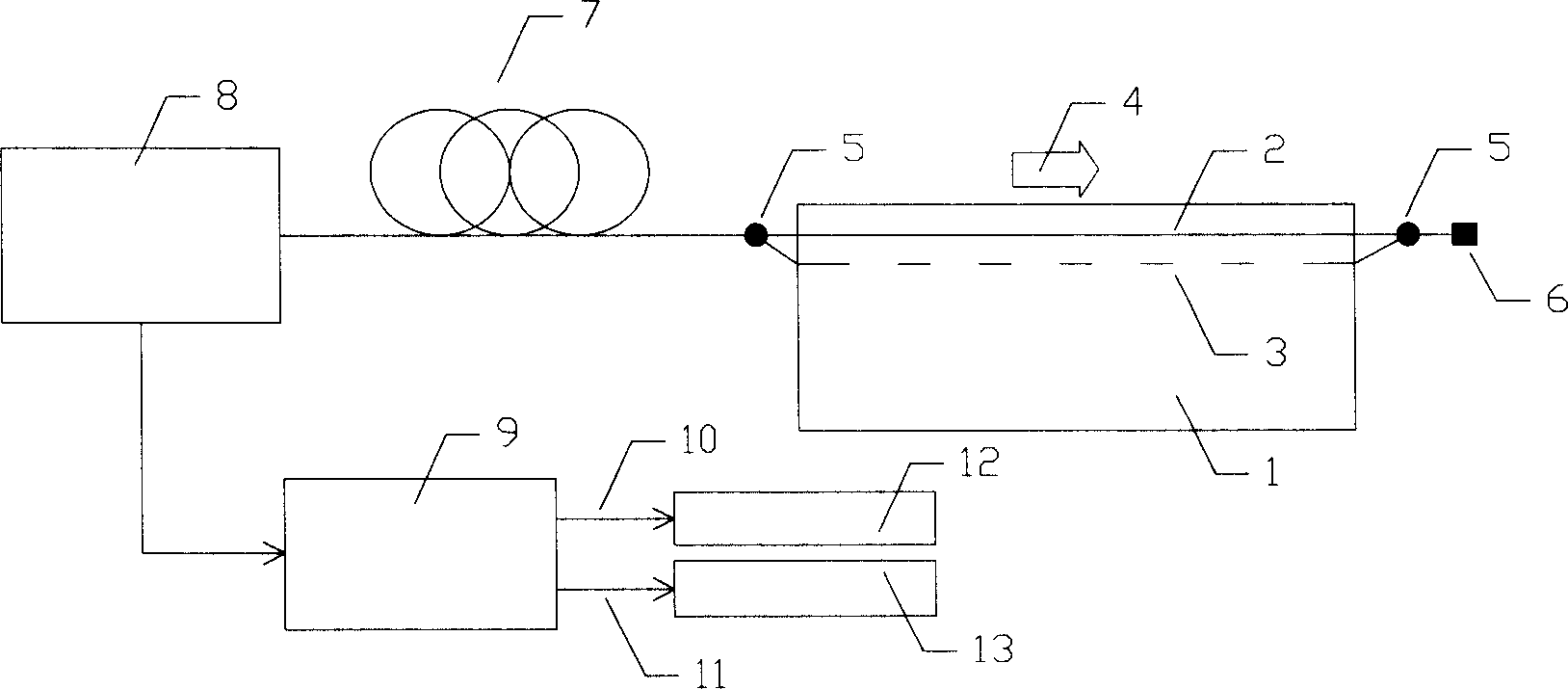

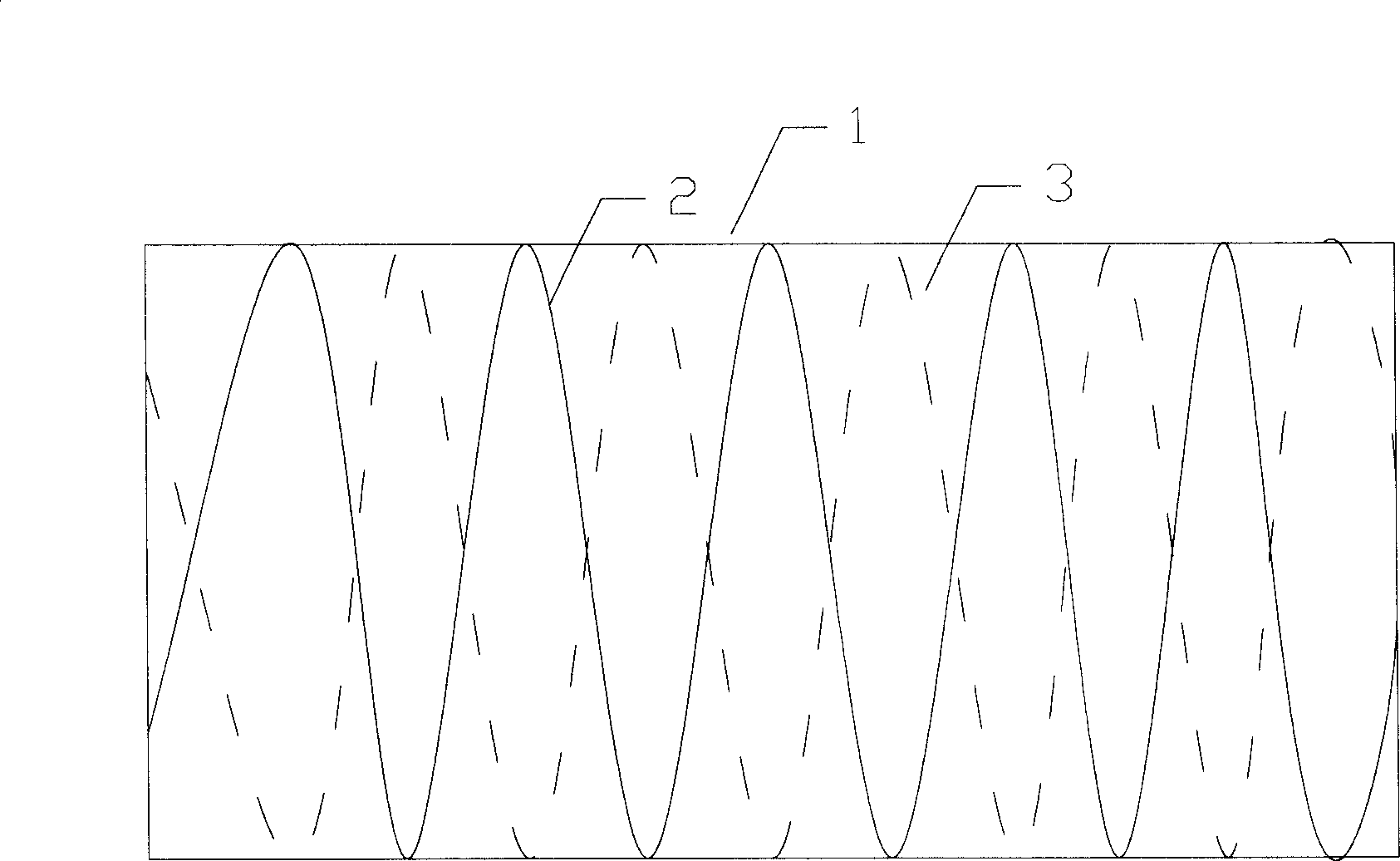

[0009] The regional distributed cavitation monitoring system for drainage structures of the present invention determines key areas for monitoring and protection of cavitation cavitation according to the level of drainage structures and the flow state of internal water flow. This area includes the surface extent and longitudinal depth along the release structure. When the discharge structure is constructed to a specified level, it is generally 15-30cm away from its water-passing surface, and the optical fiber sensor is placed on the plane (or curved surface) along the water flow direction to form a wave curve, or a cloud-shaped curve, and a continuous "8" Zigzag curves and other network structure curves are laid on this layer, and the two ends of the optical fibers are respectively connected to their respective optical cable splicing boxes. Then continue the construction to another monitoring level, generally 3-6cm away from the surface of the drainage structure. According to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com