Synchronous motor

A technology for synchronous motors and stator cores, applied to synchronous motors with stationary armatures and rotating magnets, electric components, electromechanical devices, etc., can solve the problems of not interfering with the rotor, difficult wiring of the external wiring of the coil, etc., and achieve simplified assembly Process, prevention of rotor interference, and productivity improvement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

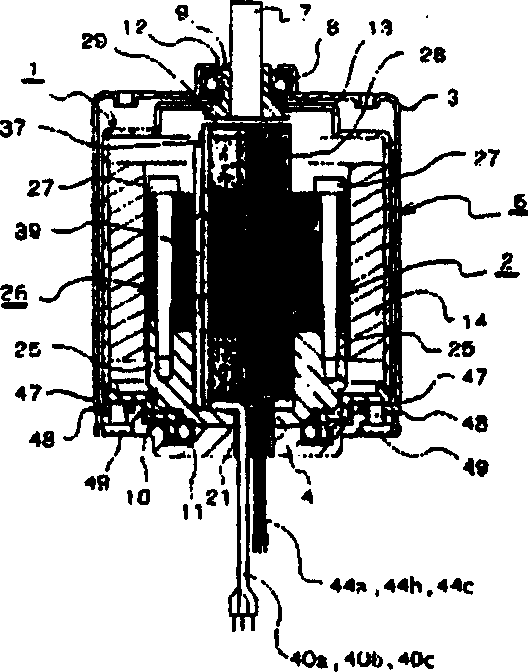

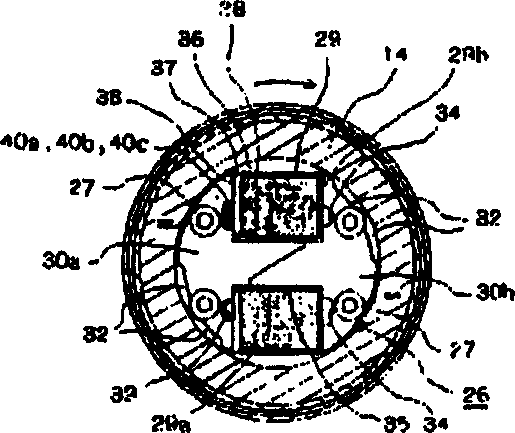

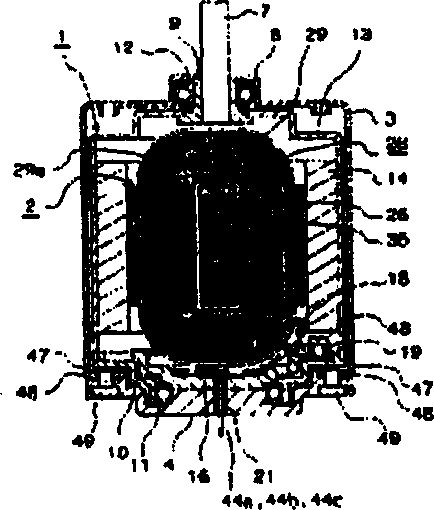

[0046] Hereinafter, the best mode for carrying out the invention will be described in detail with reference to the drawings.

[0047] Hereinafter, a two-pole synchronous motor will be described as an example of an outer rotor type synchronous motor. First, refer to Figure 1 to Figure 9 The overall configuration of the 2-pole synchronous motor of the first configuration will be described.

[0048] Figure 1A Among them, the rotor 1 and the stator 2 are accommodated in the casing 6 which is formed by stacking the upper casing 3 and the lower casing 4 up and down and is threaded and stopped by the stop screw 49 . An output shaft 7 is fitted into the upper case 3 . The output shaft 7 is pivotally supported by the upper bearing 8 fitted in the upper case 3 so that the sleeve portion 9 is rotatable.

[0049] In the rotor 1 , a rotor base member 10 is integrally fitted, and the rotor base member 10 is rotatably supported by a lower bearing 11 fitted into the lower housing 4 . As t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com