Electromechanical integrated excavator and control method therefor

An excavator and electromechanical technology, applied in the field of mechatronics excavators and control, can solve the problems of insufficient control accuracy, inaccurate positioning, and high energy consumption, and achieve the effects of overcoming large inertia, facilitating operations, and ensuring control accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

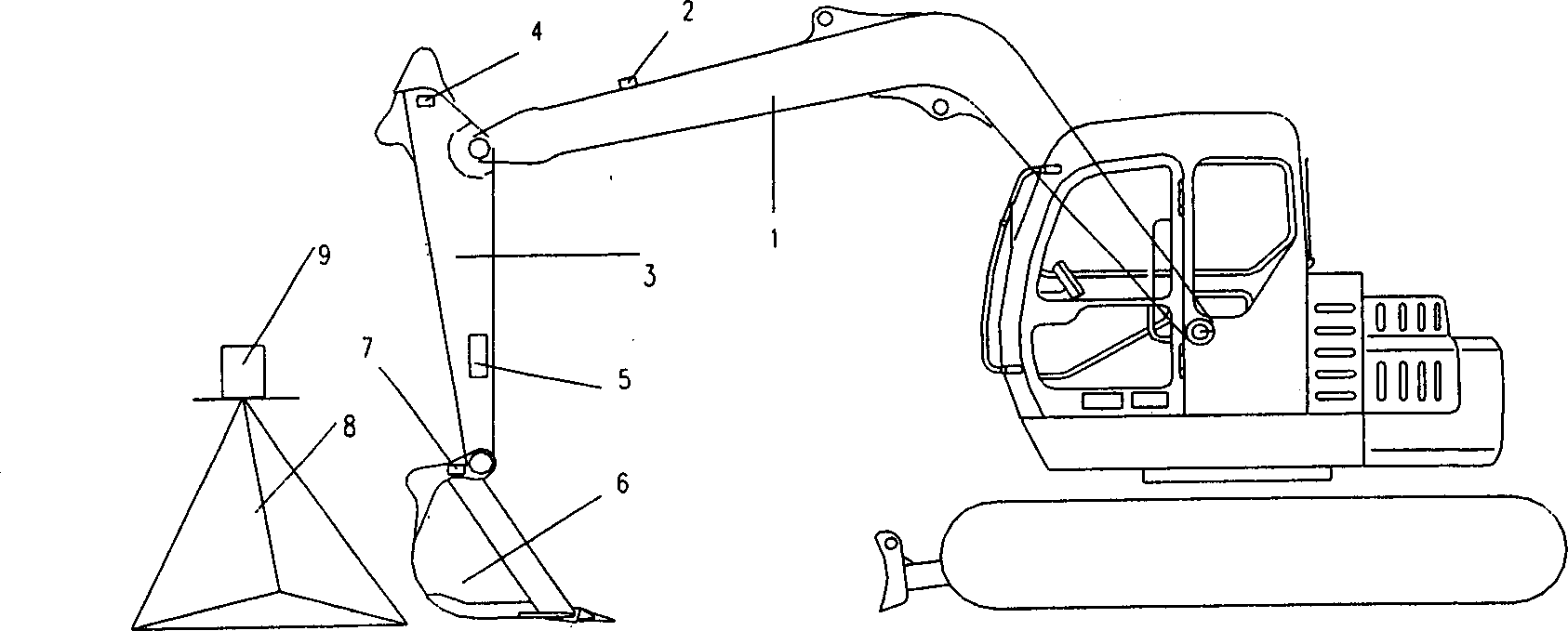

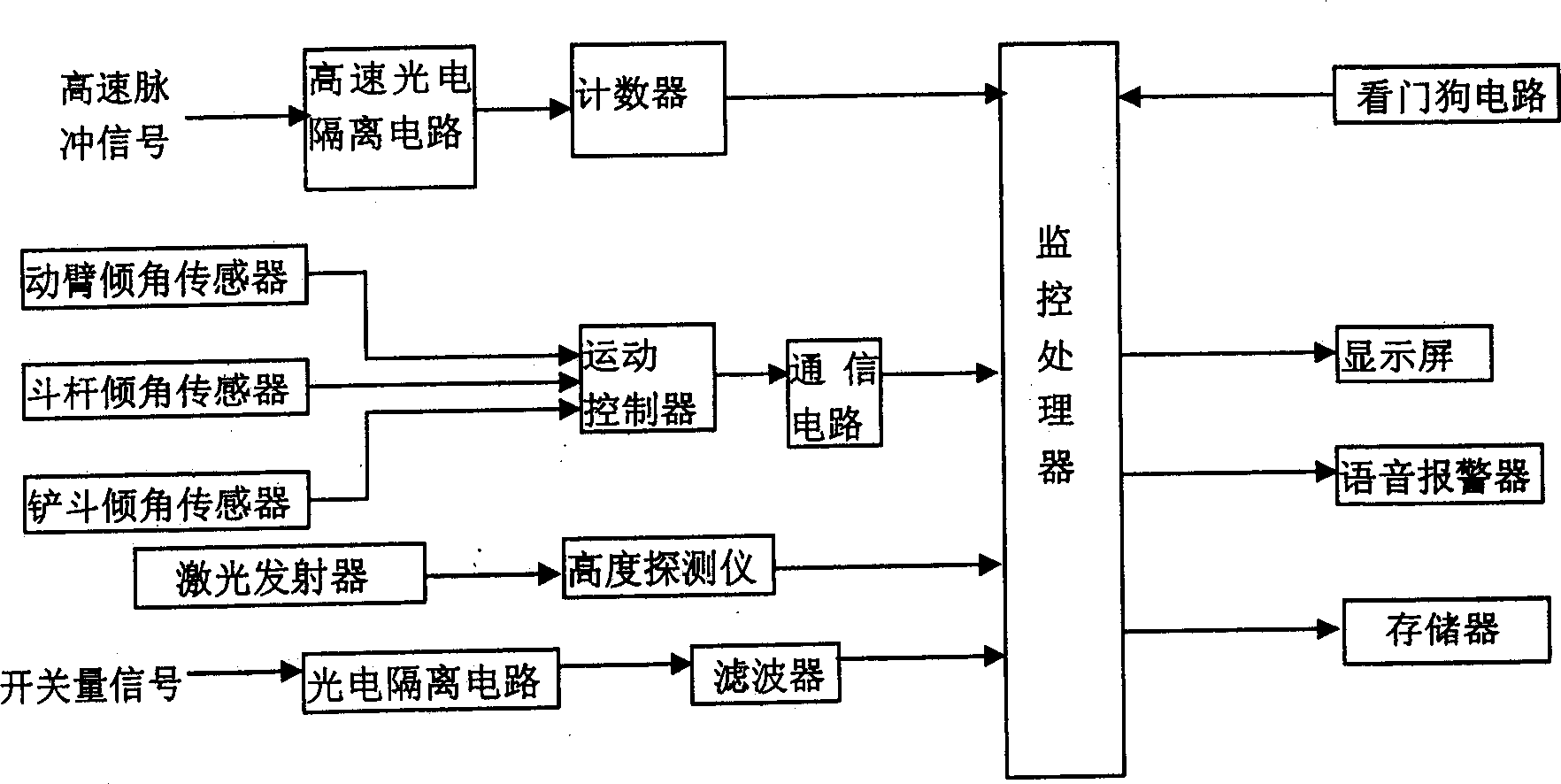

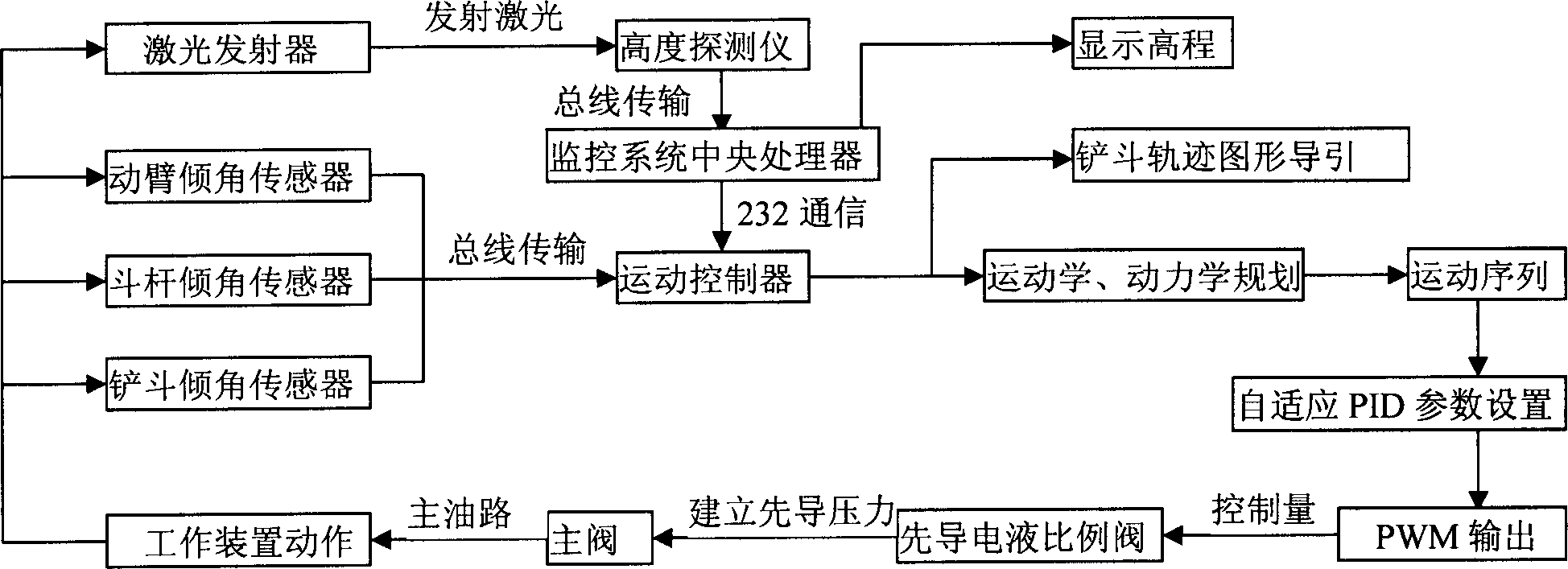

[0014] see figure 1 , The boom 1 of the working device of the excavator is provided with an inclination sensor 2 , the arm 3 is provided with an inclination sensor 4 , and the bucket 6 is provided with an inclination sensor 7 . Near the arm 3 of the excavator, a laser emitter bracket 8 is arranged, the laser emitter 9 is placed on the laser emitter bracket 8, the height detector 5 is fixed on the excavator arm 3, and the output end of the height detector 5 is connected to the monitor The processor is connected. When the excavator is working, adjust the level of the laser transmitter bracket 8, the laser head on the laser transmitter 9 rotates and emits laser light, the height detector 5 receives the laser signal, measures the relative height of the laser beam relative to the zero position, and transmits it to the monitor through the bus The central processing unit of the system displays the elevation on the display screen of the monitoring system, and then transmits it to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com