Multi-wavelength LED structure and making process thereof

A light-emitting diode, multi-wavelength technology, used in semiconductor devices, electrical components, circuits, etc., can solve the problems of yellow halo, inaccuracy, and unpredictable color shift.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the composition and implementation of the present invention clear to your examiner, the description is as follows in conjunction with the drawings:

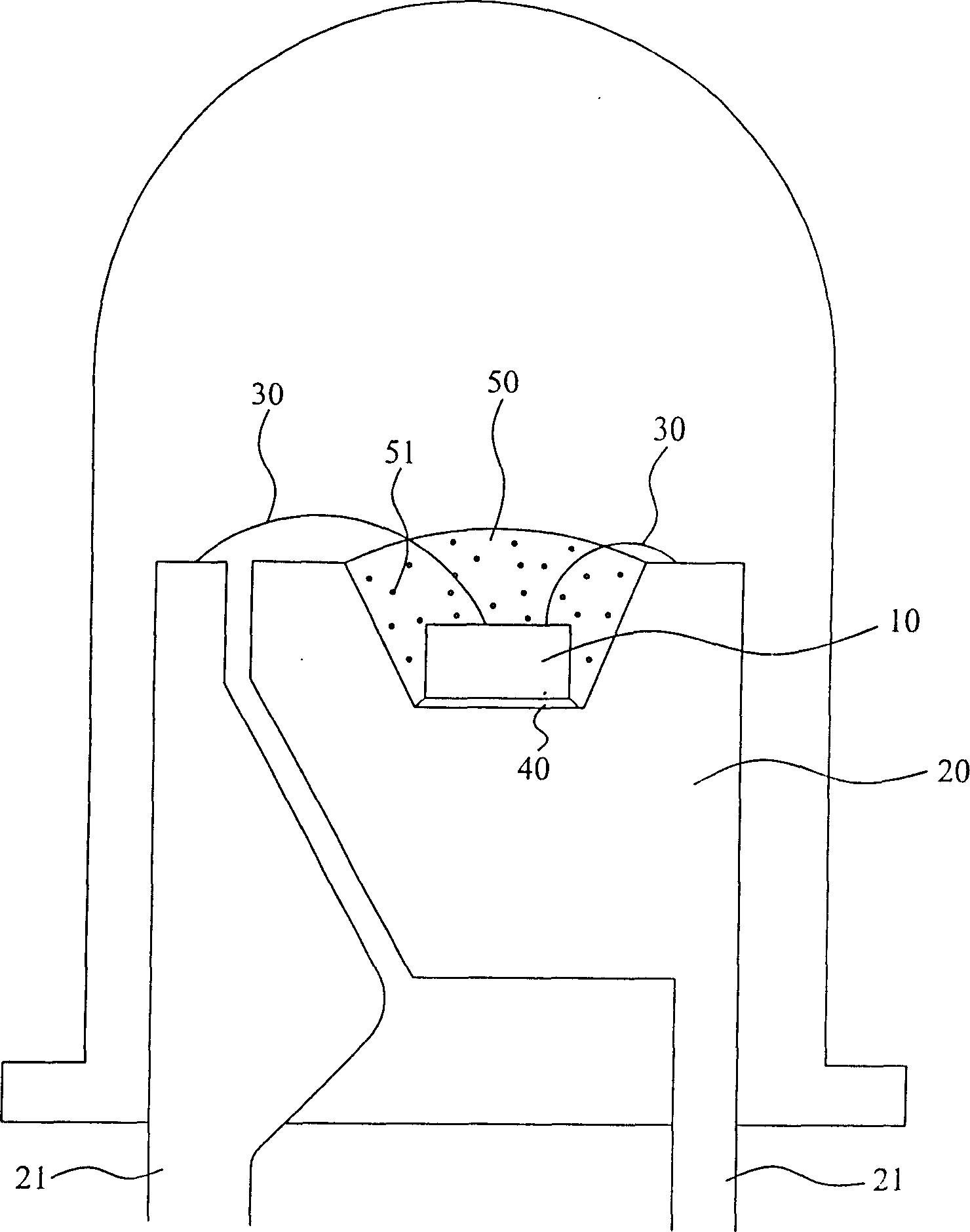

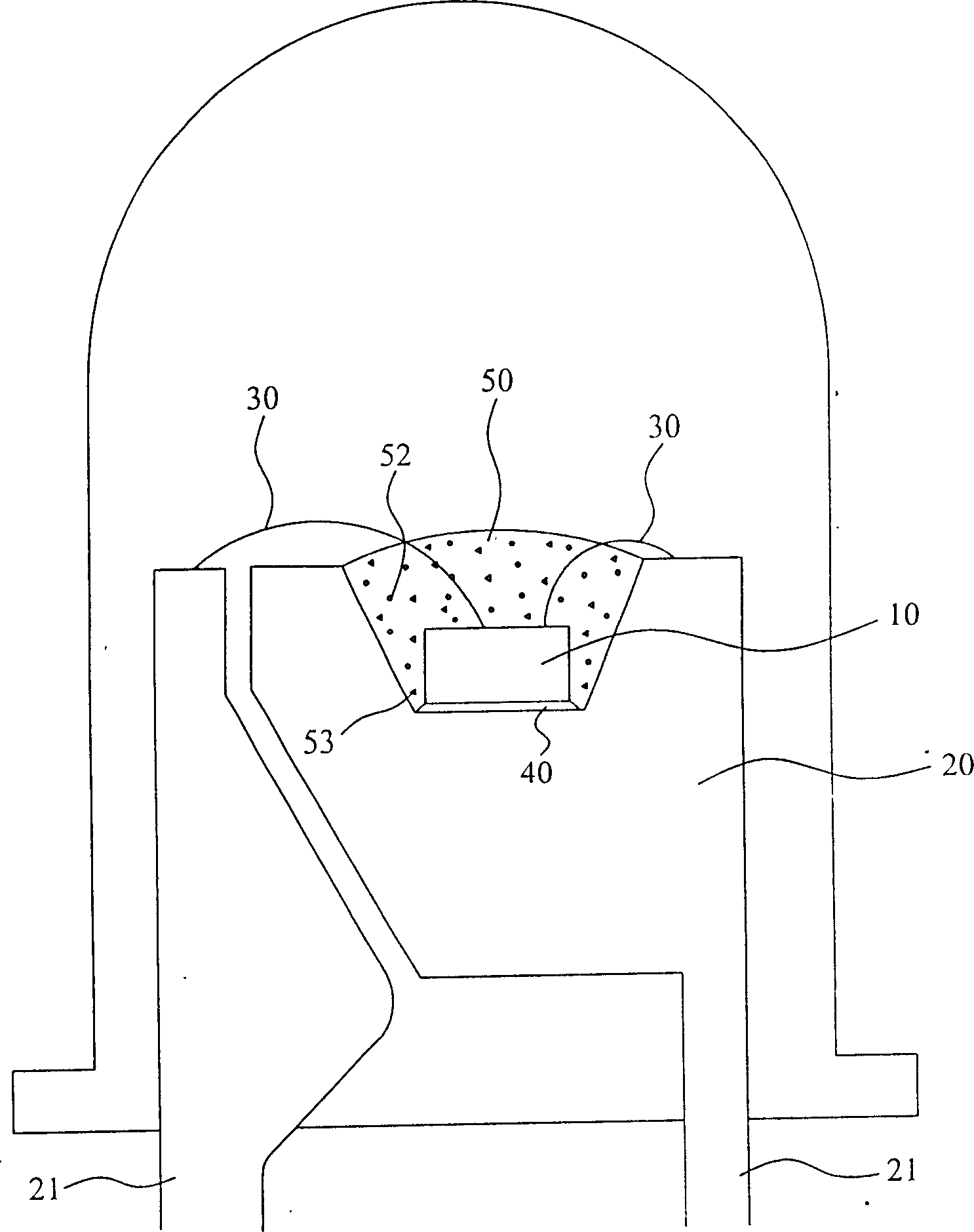

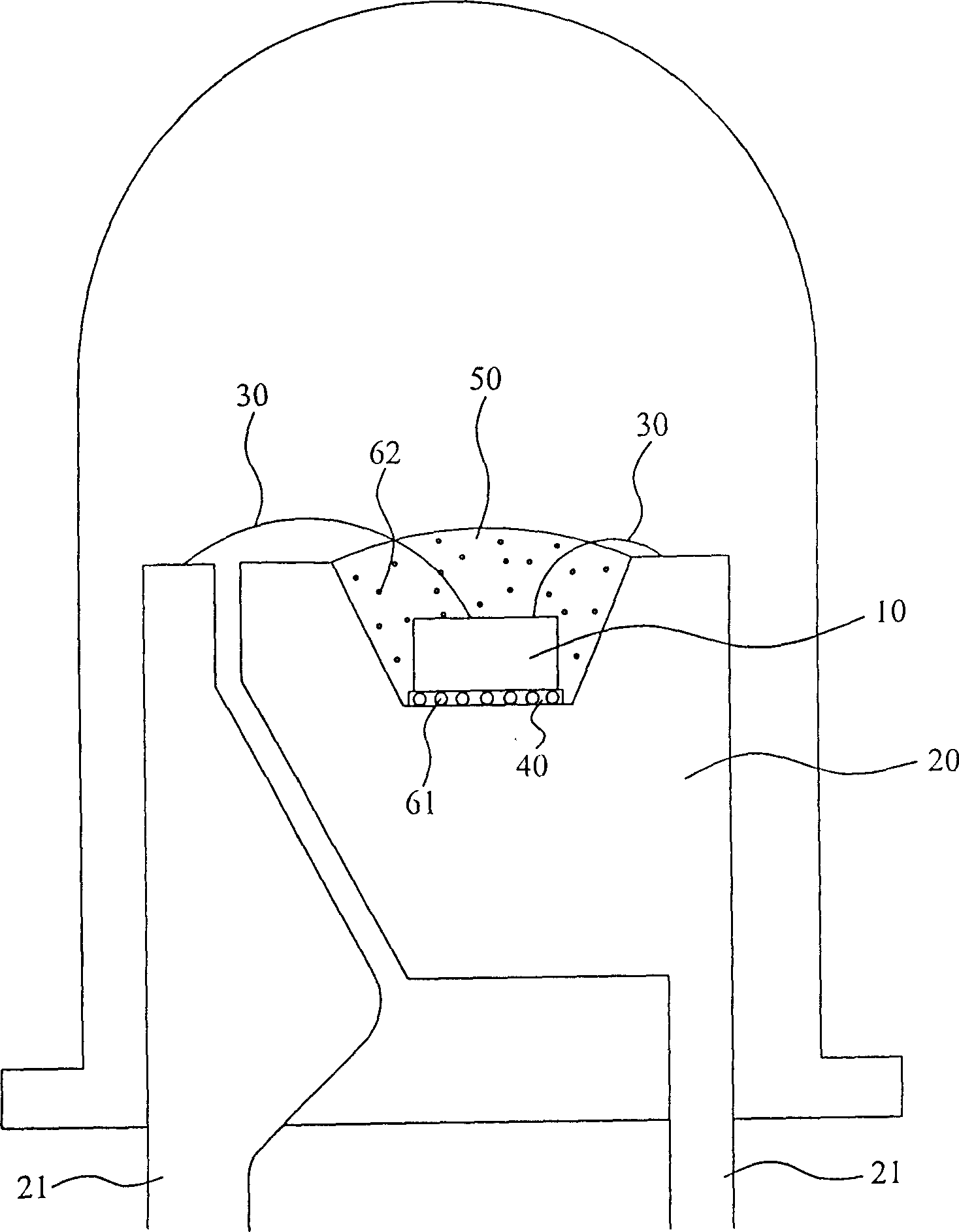

[0025] The "multi-wavelength light-emitting diode structure and its manufacturing process" of the present invention, the basic structure of the overall multi-wavelength light-emitting diode is as follows image 3 As shown, the light-emitting chip 10 is also fixed in a carrier 20 by using the crystal-bonding glue 40, and the connection between the light-emitting chip 10 and the electrode terminal 21 is formed by using the gold wire 30, and the light-emitting chip 10 is fixed by the fluorescent glue 50 having a fluorescent material. Covering is used to make the light source of the light-emitting chip excite the fluorescent material of the fluorescent glue 50 under the power-on effect of the light-emitting chip 10, so as to form a desired light color.

[0026] Among them, the overall multi-wavelength light-em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com