Automatic brick production line

An automatic production line and brick-making machine technology, which is applied in ceramic molding workshops, unloading devices, ceramic molding machines, etc., can solve problems such as high labor intensity, restricting product quality and productivity, and inability to carry out production steps consistently, so as to reduce labor Strength, quality and productivity improvement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Best practice:

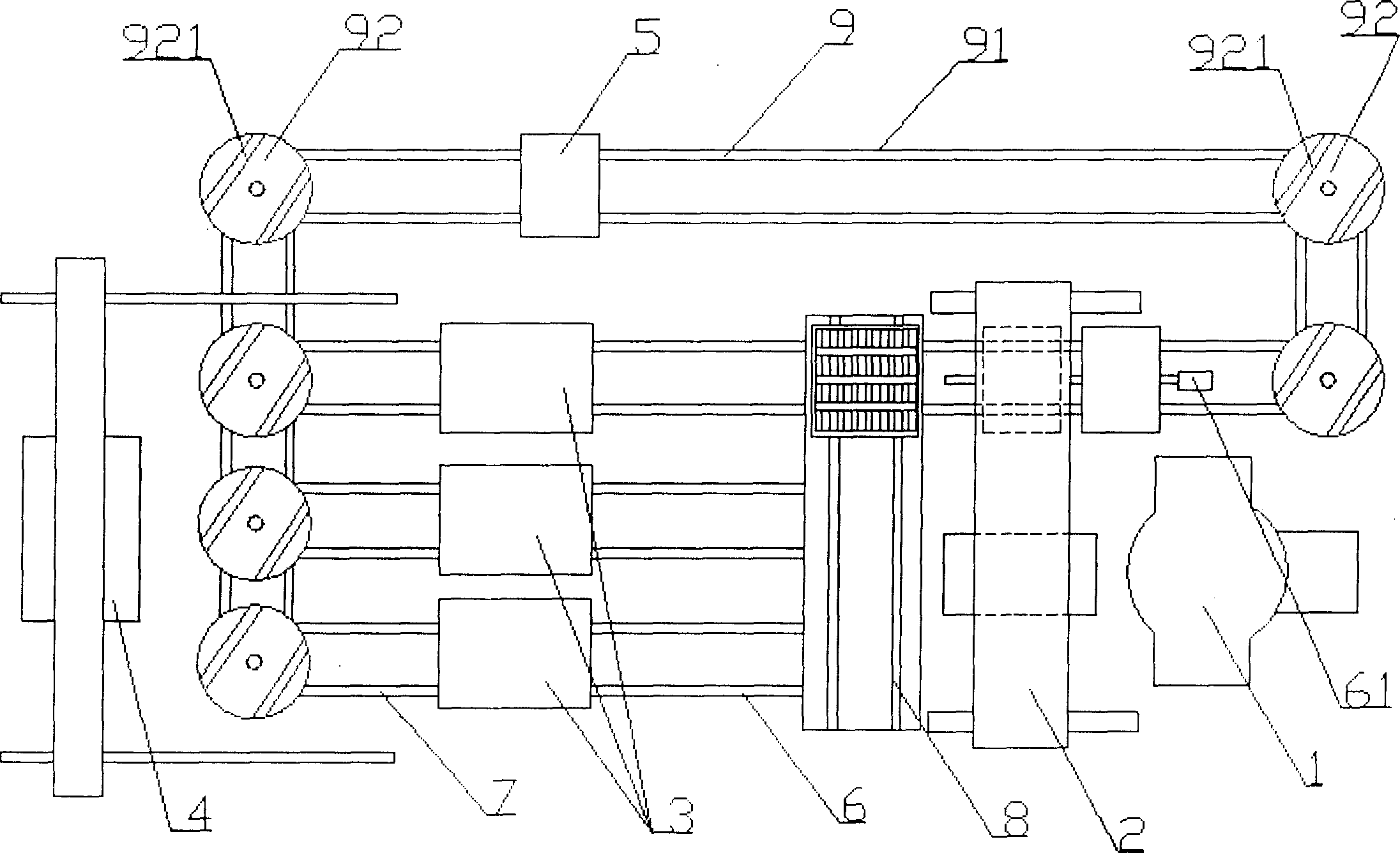

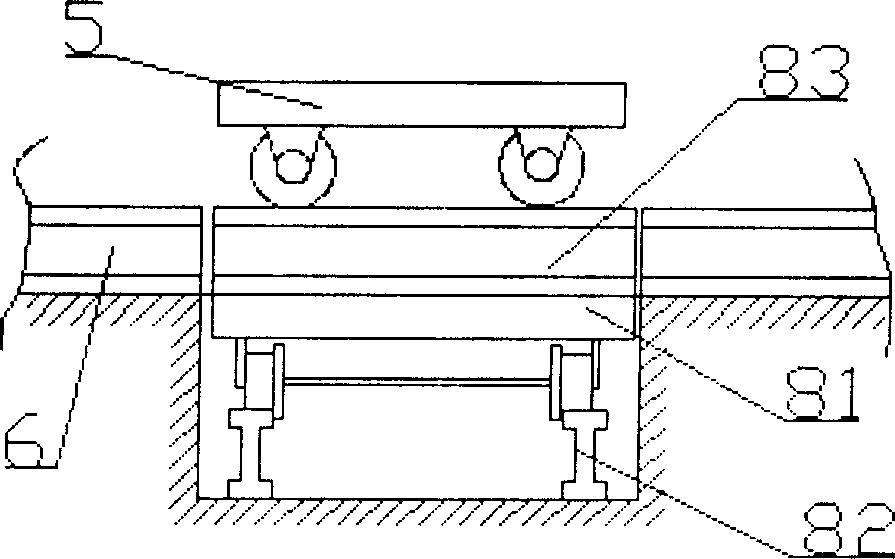

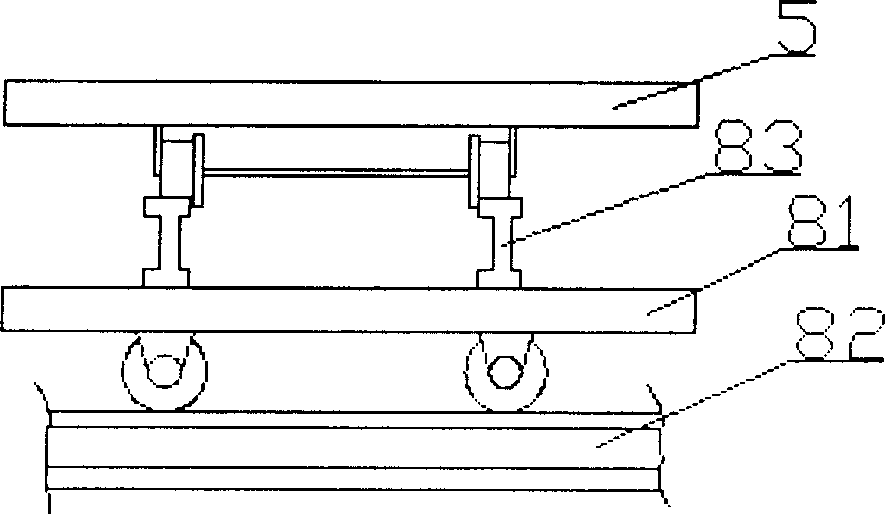

[0033] refer to figure 1 , Figure 4, an automatic production line for bricks, including a brick making machine 1, a palletizer 2, an autoclave 3, a brick unloading machine 4 and a maintenance trolley 5, and also includes a first conveyor 6 and a second conveyor 7, and the first conveyor 6 Connected between the brick making machine 1 and the autoclave 3, the second conveyor 7 is connected between the autoclave 3 and the brick unloading machine 4, and the maintenance trolley 5 is installed on the first conveyor 6 and the second conveyor 7 , and move on the first conveyor 6 and the second conveyor 7. Both the first conveyor 6 and the second conveyor 7 are guide rail conveyors, including a conveying guide rail and a conveying drive mechanism, and the maintenance trolley 5 is driven to move on the conveying guide rail by the conveying drive mechanism. Between the two conveying rails of the first conveyor 6 there is also a step control mechanism 61 that c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com