Optical fiber grating sensing system for measuring distribution load on rotating wings

A fiber grating and distributed load technology, which is applied in the direction of using optical devices to transmit sensing components, measuring devices, and measuring the force of changes in optical properties of materials when they are stressed, can solve problems such as immature technology and achieve measurement high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

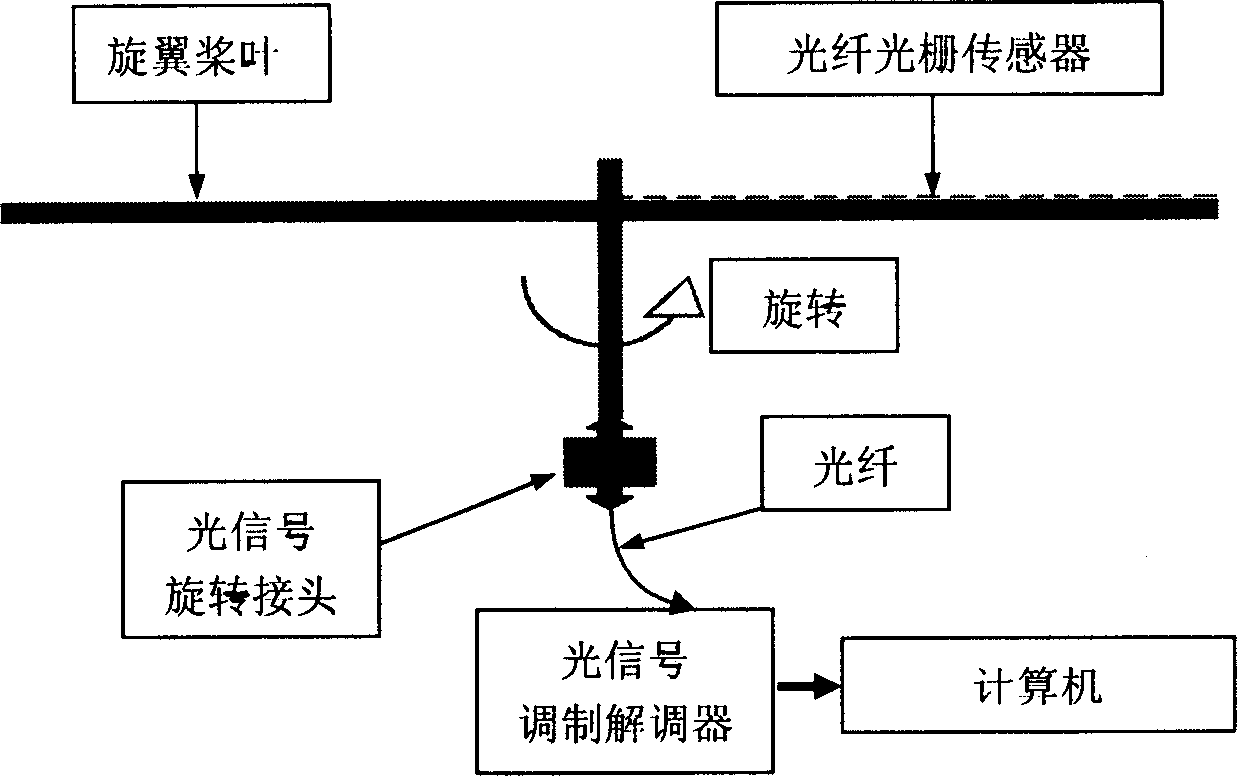

[0011] figure 1 It is a compositional block diagram of the rotor distributed load fiber grating sensing and measuring system of the present invention. It includes a Fiber Bragg Grating sensor pasted on the measuring surface of the rotor blade, an optical signal rotary joint, an optical signal modem, and a computer. The specific work process and implementation steps are as follows:

[0012] (1) Paste a string of Fiber Bragg Grating sensors at the measurement position on the upper surface of the blade;

[0013] (2) Connect the optical fiber on the paddle to the optical signal rotary joint, then lead the optical fiber out from the optical signal rotary joint, and connect it to the optical signal modem to transmit, receive and collect the optical signal. The optical signal modem is connected with the computer, and the collected signal is recorded and analyzed by the computer;

[0014] (3) Convert the dynamic optical signal collected at each measurement point under a certain tes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com