Dual-axis resonance type micromechanical accelerometer

An accelerometer and resonance technology, which is used in the measurement of acceleration, velocity/acceleration/shock measurement, measurement devices, etc., can solve the problem of insufficient sensitivity and resolution, and achieve high resolution, differential output, and good manufacturability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

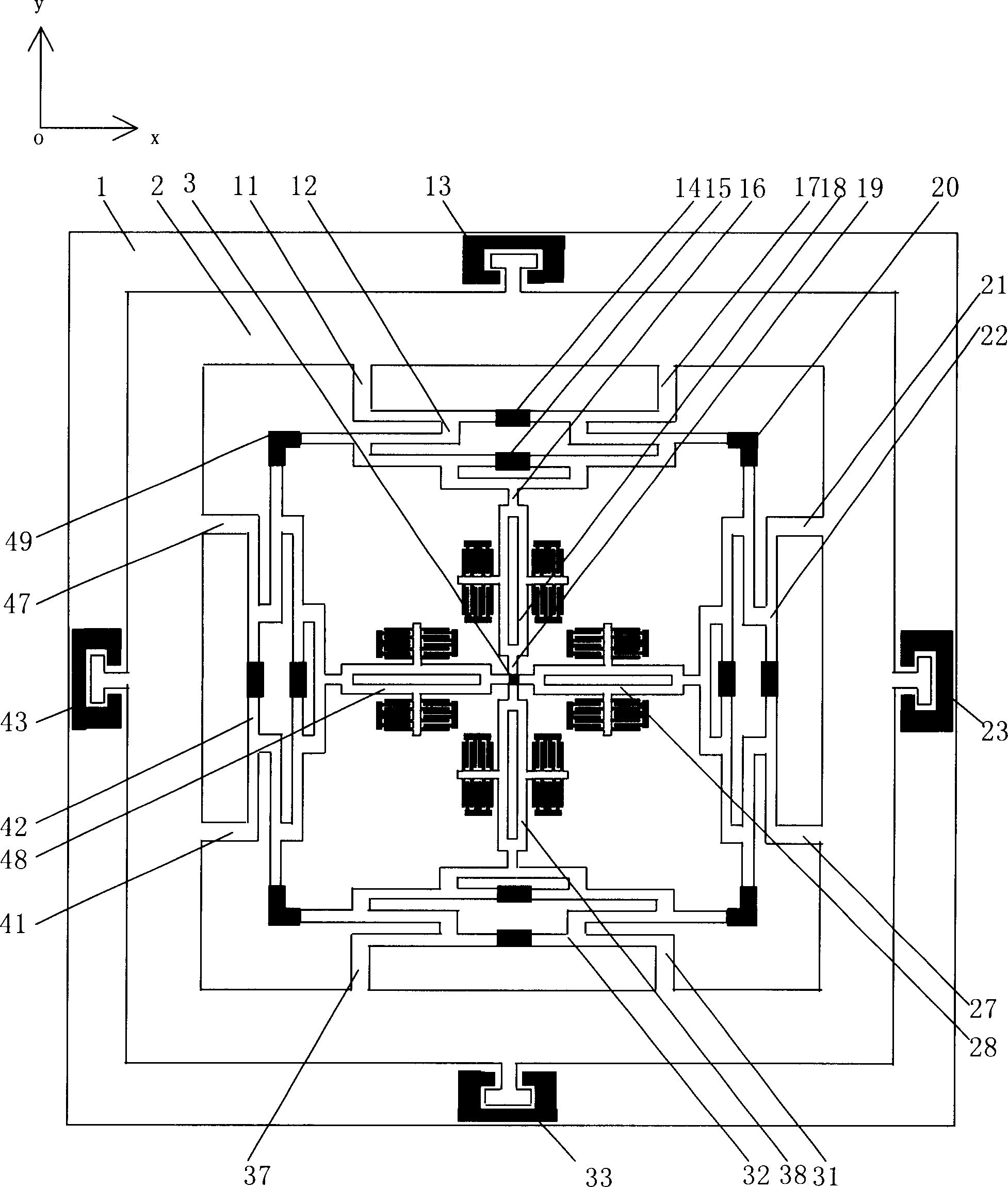

[0009] Such as figure 1 As shown, the present invention includes a substrate 1, a mass block 2, 8 cantilever beams 11, 17, 21, 27, 31, 37, 41, 47, 4 lever amplification mechanisms 12, 22, 32, 42, 4 tuning forks 18, 28, 38, 48, 4 sets of drive electrodes, detection electrodes, tooth pivots and 4 stops 13, 23, 33, 43, the whole structure is a centrally symmetrical figure, and a mass block 2 is sensitive to two orthogonal directions acceleration. The mass block 2 is in the shape of "back", and in the middle of the mass block 2 are 8 cantilever beams 11, 17, 21, 27, 31, 37, 41, 47, 4 lever amplification mechanisms 12, 22, 32, 42, 4 Tuning forks 18, 28, 38, 48 and 4 groups of tooth hubs, drive electrodes, and detection electrodes. The elastic support composed of 8 cantilever beams 11, 17, 21, 27, 31, 37, 41, 47 skillfully realizes the decoupling of two orthogonal directions, so that the sensitivity and resolution of the two directions are high; the lever The mechanism 12 is comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com