Demulsifier

A technology of demulsifiers and additives, applied in the field of demulsifiers, can solve the problems of difficult to achieve the purpose of demulsification and dehydration of oil-water emulsions in oilfields, poor demulsification ability, complex types of water emulsions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

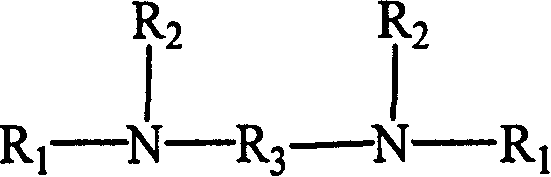

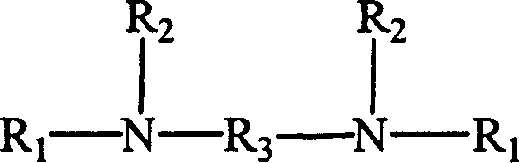

Method used

Image

Examples

Embodiment 1

[0019] 37.5 grams (21 parts) of petroleum sulfonate acidification products are put into a 250ml conical flask, add 125 grams (70 parts) of absolute ethanol, and slowly add 16 grams (9 parts) of N, N'-bis(dec Dialkylmethyl)-hexamethylenediamine, after the solution is uniform, add 1.5 grams of glacial acetic acid with a mass percent content of 60%, to obtain the demulsifier EXAM-1.

Embodiment 2

[0021] by C 20 ~C 24 The mixed alkenes and naphthalene are alkylated, and the product is sulfonated to obtain a sulfonic acid with an alkylaryl group. Get 16.1 grams (35 parts) of the above product and put it into a 100ml Erlenmeyer flask, add 24 grams (52 parts) of n-butanol, slowly add 5.6 grams (13 parts) of N, N'-bis(hexadecylmethyl) under stirring )-p-xylylenediamine, stirred evenly to obtain demulsifier EXAM-2.

Embodiment 3

[0023] by C 20 ~C 24 The mixed alkenes and naphthalene are alkylated, and the product is sulfonated to obtain a sulfonic acid with an alkylaryl group. Take 30 grams (15 parts) of the above product and put it into a 250ml Erlenmeyer flask, add 160 grams (80 parts) of methanol, and slowly add 10 grams (15 parts) of N, N'-bis(dodecylmethyl)- 2,3-dihydroxybutanediamine, stirred evenly to obtain demulsifier EXAM-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com