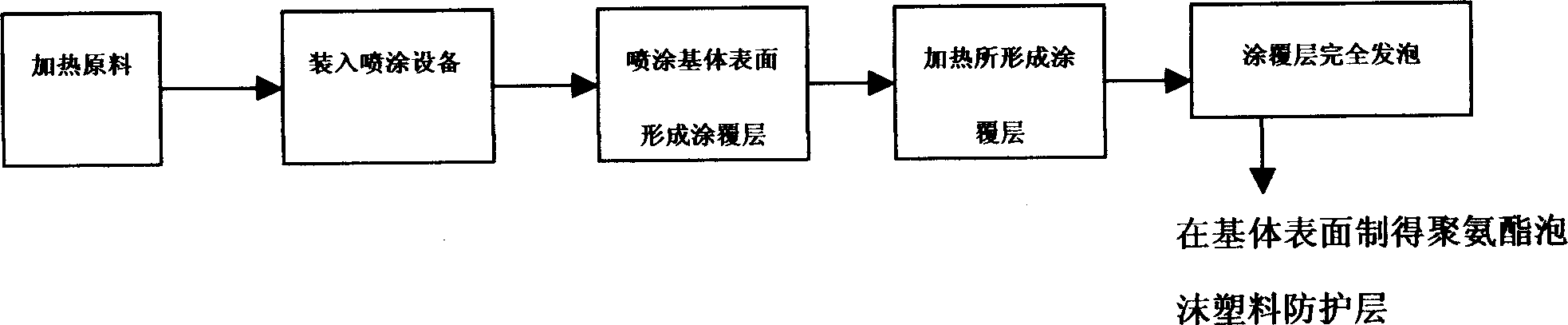

In-situ spraying process of protective polyurethane plastic foam layer

A technology of polyurethane rigid foam composite material and foam plastic, which is applied in the direction of coating, device for coating liquid on the surface, pretreatment surface, etc. Low raw material consumption, the effect of reducing raw material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] At a construction site in Nantong City, Jiangsu Province, the on-site spraying construction process of the present invention is adopted, and the concrete beams and columns of the building are used as the substrate, and the polyurethane foam plastic raw material is sprayed on-site to form a polyurethane foam protective layer on the surface of these substrates. The substrate is insulated.

[0026] During construction, the polyurethane foam raw material used is a 1:1 mixture of flame-retardant polyurethane rigid foam combination material (component A) that meets the Q / 3204AGC008 standard, that is, white material and thick MDIPM200, that is, black material; the equipment for heating the above raw materials is Industrial electric furnace; the spraying equipment is FF-1600 high-pressure airless polyurethane sprayer; the equipment for heating the coating layer or the subsequent coating layer is a liquefied gas blowtorch.

[0027] During construction, the ambient temperature is -...

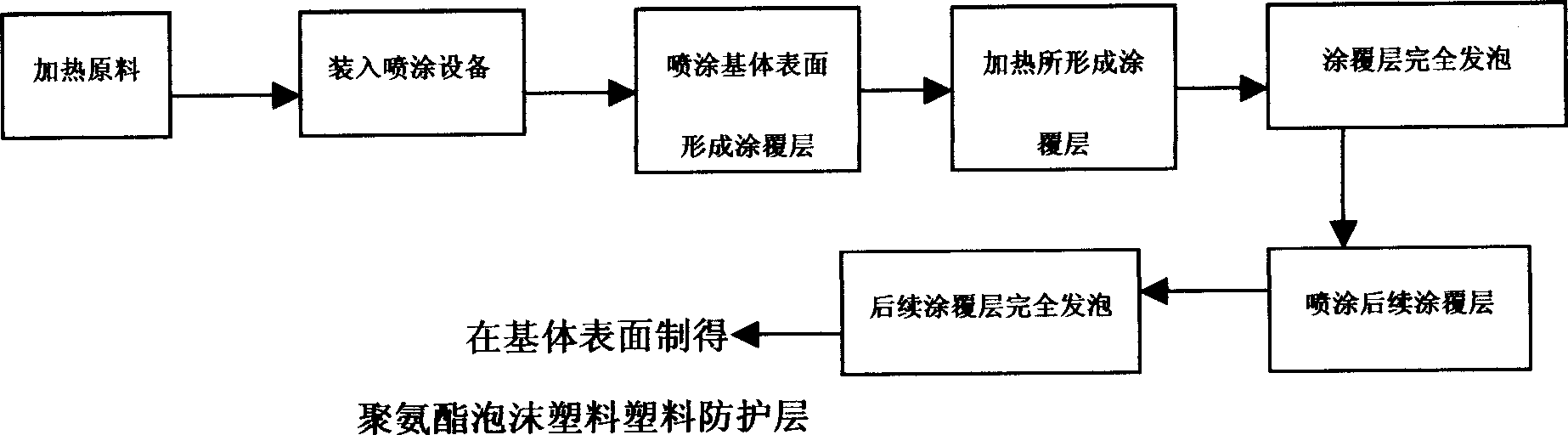

Embodiment 2

[0031] In the R & D and production base of Changzhou Institute of Building Sciences, Jiangsu Province, the on-site construction process of the present invention is adopted, and the concrete inner wall and plank of the base building are used as the substrate, and the polyurethane foam plastic raw materials are sprayed on site to form polyurethane foam on the surface of these substrates. The protective layer is used to insulate the substrate.

[0032] During construction, the polyurethane foam raw material used is a 1:1 mixture of non-flame retardant polyurethane rigid foam combination material (component A) that meets the Q / 3204AGC008 standard, that is, white material and thick MDIPM200, that is, black material; the equipment for heating the raw material is Industrial electric furnace; the spraying equipment is FF-1600 high-pressure airless polyurethane sprayer; the equipment for heating the coating layer is infrared lamp.

[0033] During construction, the ambient temperature i...

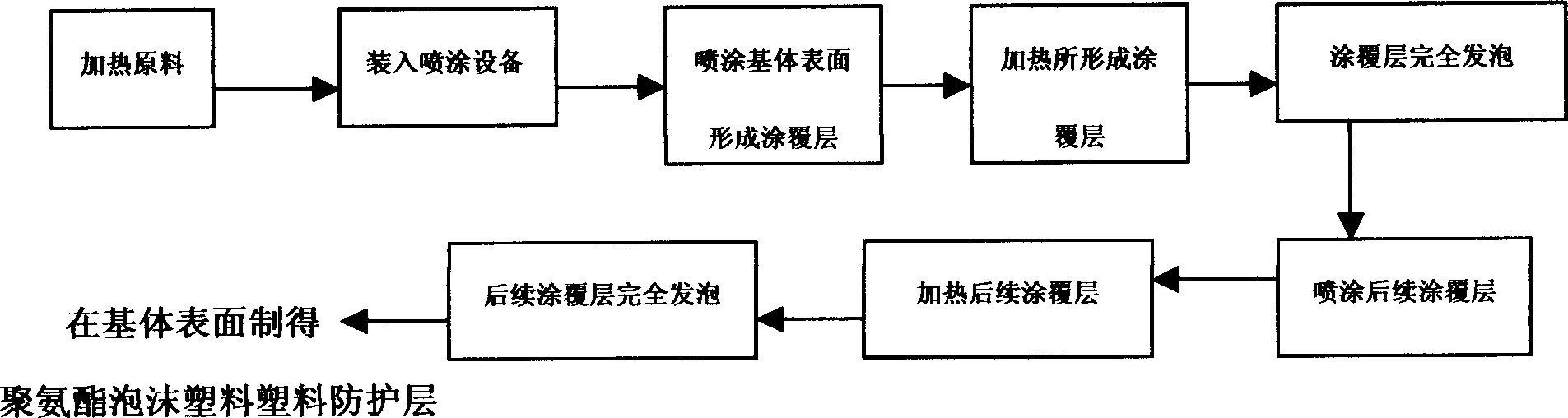

Embodiment 3

[0037] In a cold store in Changzhou City, Jiangsu Province, the on-site construction process of the present invention is adopted, and the concrete inner wall of the cold store and the cast iron pipe are used as the substrate, and the polyurethane foam plastic raw material is sprayed on site to form a polyurethane foam protective layer on the surface of these substrates to keep the substrate warm. , Waterproof treatment.

[0038] During construction, the ambient temperature is -40°C to -30°C.

[0039] Construction used raw material, various equipment are all identical with embodiment 1.

[0040] The construction process is as follows:

[0041] Such as figure 2 and image 3 As shown, the flame-retardant polyurethane rigid foam combination material (A component) that meets the Q / 3204AGC008 standard, that is, the white material, and the thick MDIPM200, that is, the black material, are heated to 30°C respectively, and the weight ratio is 1:1, and they are respectively loaded in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com