Rocker packing machine

An arm case packer and rack technology, which is applied in the field of large case packers, can solve problems such as the inability to meet the production of multi-variety bottle type and multi-layer bottling, and achieve high production efficiency, fast bottling speed, and electrical load. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

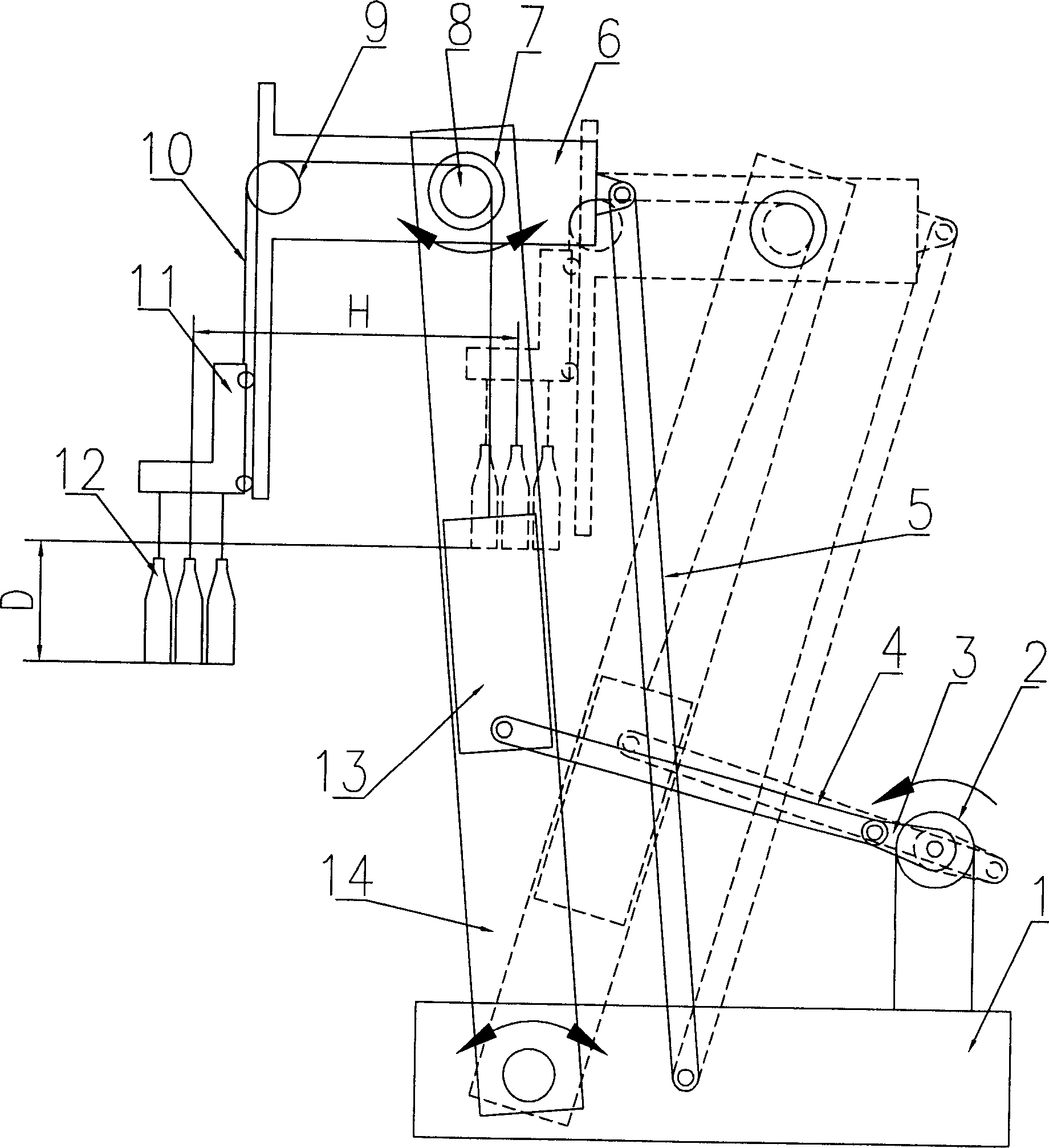

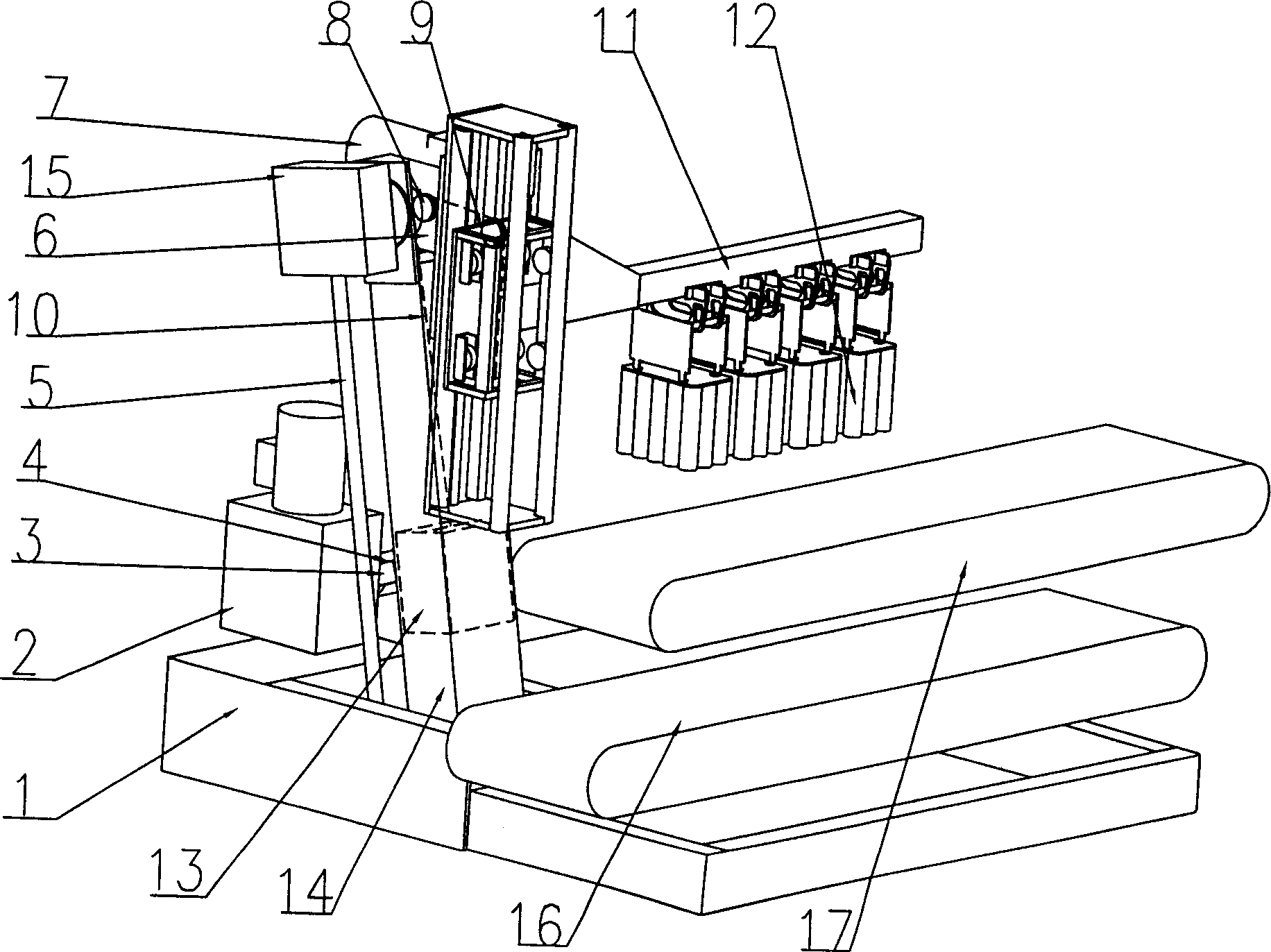

[0018] A rocker arm case packer, such as figure 1 , 2 Shown: comprise frame 1, catch bottle mechanism 12, translation mechanism and lifting mechanism. figure 1 Among them, H- indicates the horizontal movement distance of the bottle; D- indicates the vertical movement distance of the bottle.

[0019] The translation mechanism is a parallelogram link mechanism, which includes a first parallel link 14, a second parallel link 5 and a swing arm 6 hinged at the upper ends of both. A slide rail is provided under the swing arm 6 . The first parallel link 14 is a load-bearing support square tube, which is provided with horizontal hinges along the lower ends of the first and second parallel links 14, 5 with the frame 1; Drive motor 2, a crank 3 and crank connecting rod 4 are hinged between the axle of this motor 2 and the first parallel connecting rod 14, and the length of its connecting rod 4 is adjustable. The lifting mechanism is located on the swing arm 6, and the bottle-grabbin...

Embodiment 2

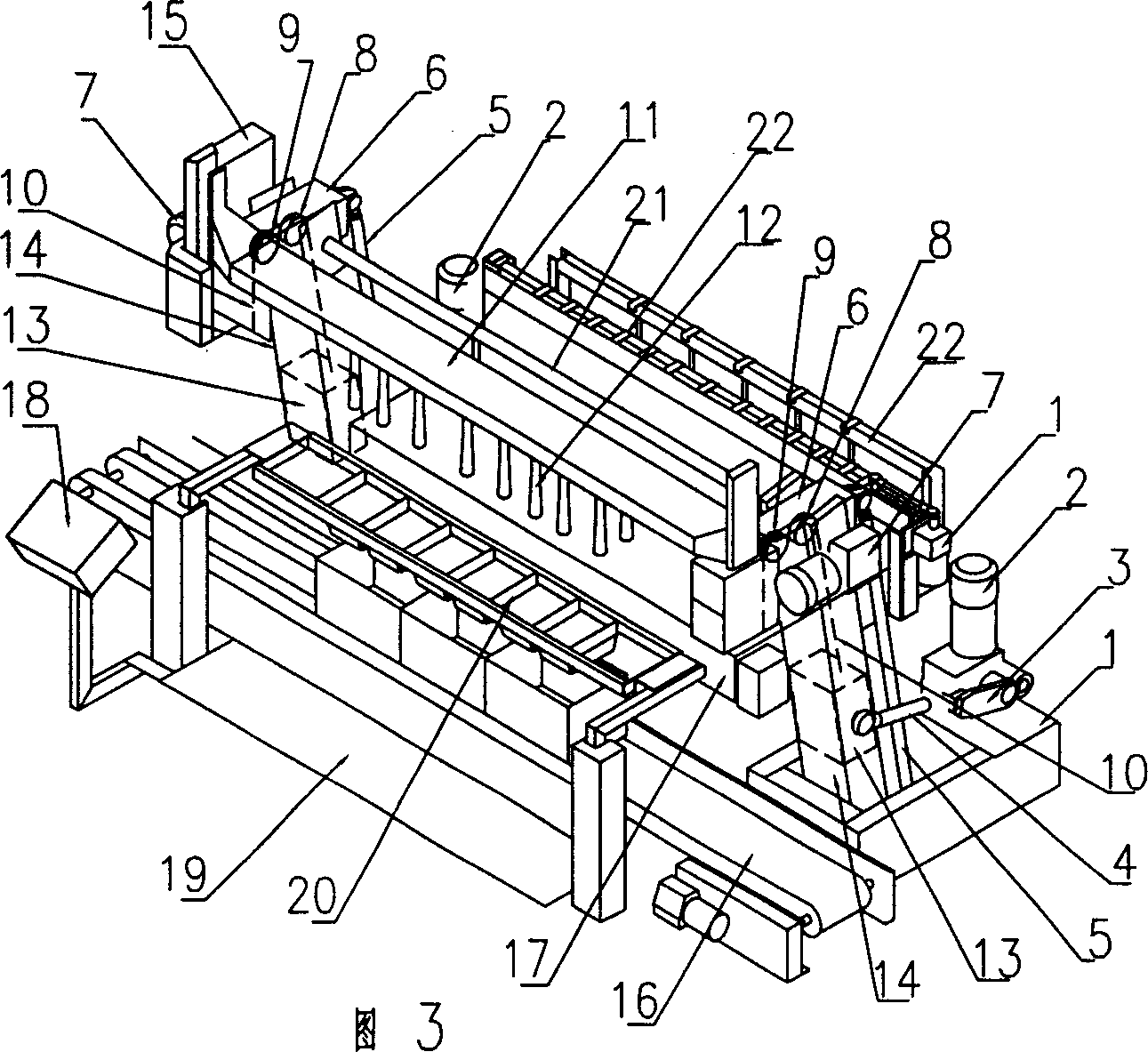

[0028] As shown in Figure 3, the main difference between the rocker arm case packing machine of this embodiment and Embodiment 1 is that two groups of translation mechanism and lifting mechanism are arranged side by side, and are connected to each other in the shape of a door by a synchronous shaft 21 and a hanger 11. synchronized movement.

[0029] The rocker arm case packer of this embodiment is suitable for a production line with more than 24,000 bottles per hour (inclusive), and the power of two rocker arm drive motors 2 (horizontal movement) and two lifting motors 7 (vertical movement) is 6KW.

[0030] The working principle is:

[0031] A. Frame 1, two pairs of first parallel connecting rods 14, second parallel connecting rods 5 and swing arm 6 with slide rails form two parallelogram structures, and the synchronous shaft 21 is connected between them to make the parallelogram structures on both sides move synchronously , to ensure that the bottle moves smoothly horizonta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com