Polyvinyl chloride water-proof engineering cloth and its manufacturing method

A polyvinyl chloride, manufacturing method technology, applied in the direction of chemical instruments and methods, synthetic resin layered products, laminating devices, etc., to achieve the effects of improving mechanical properties, preventing leakage, and having obvious effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

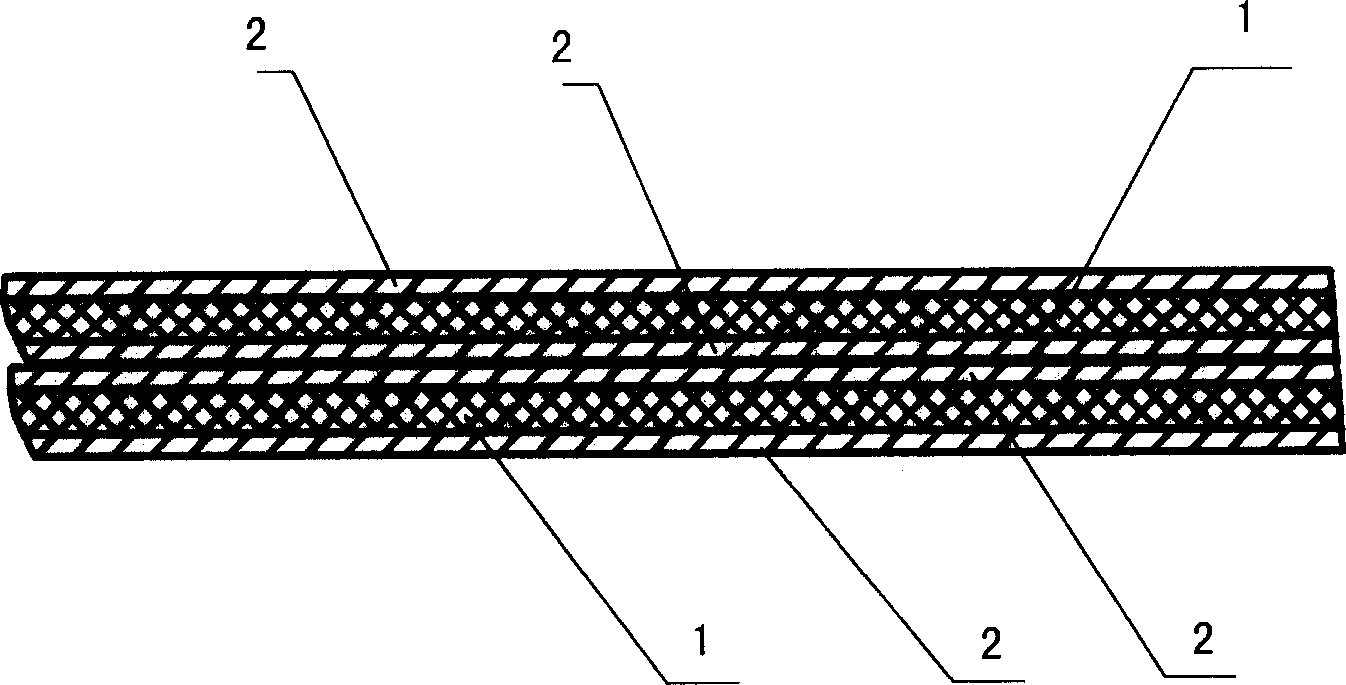

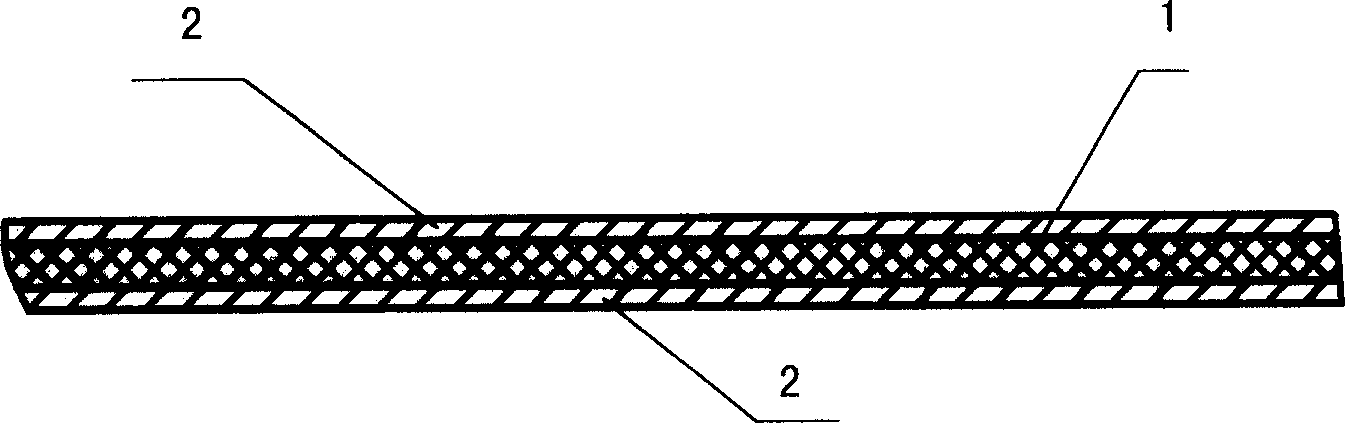

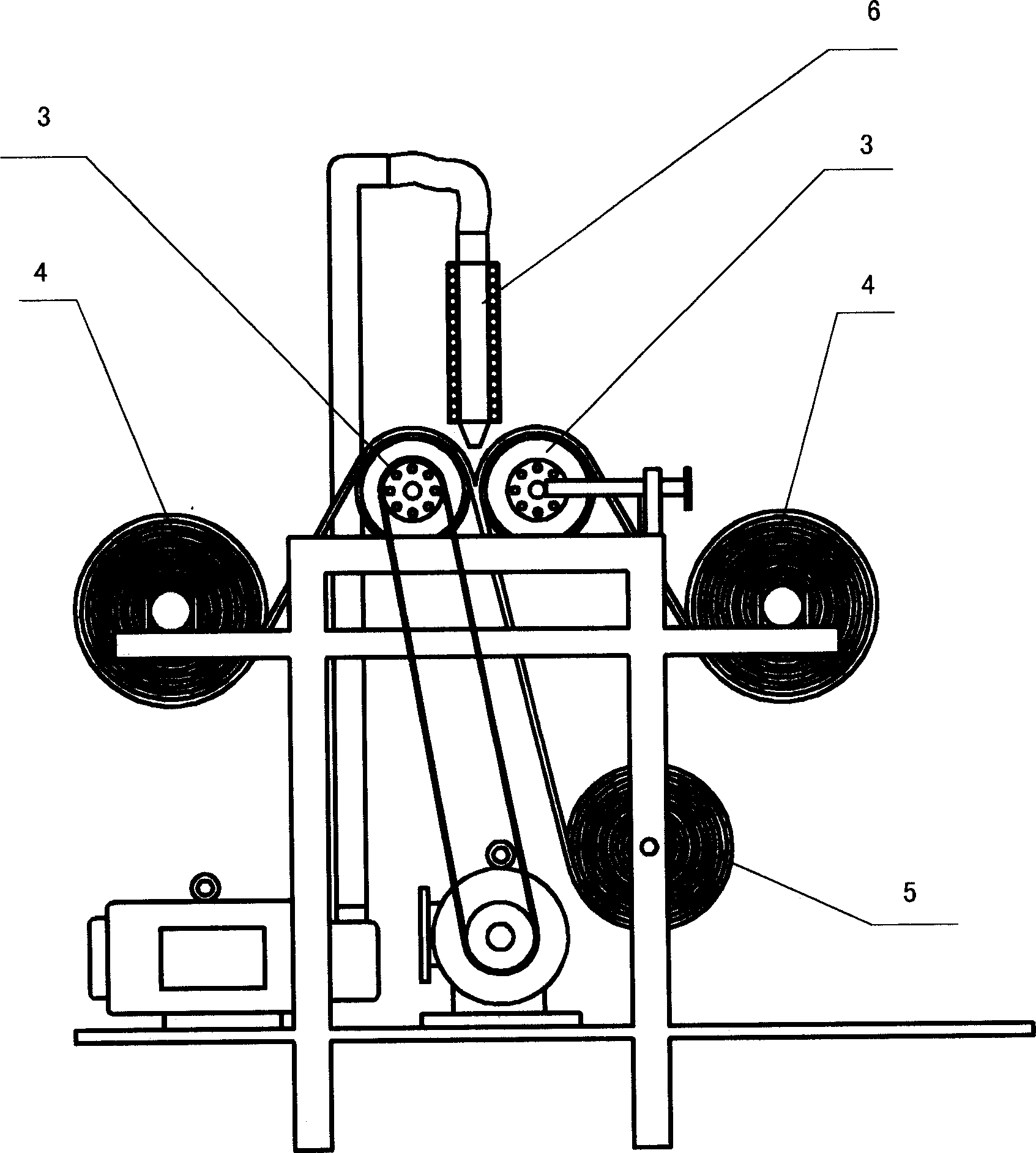

[0050] According to the accompanying drawings, the structure of the present invention is described in detail. A polyvinyl chloride waterproof engineering cloth proposed by the present invention immerses the base layer 1 in the polyvinyl chloride polymer coating to form uniform polyvinyl chloride on both sides of the woven base layer 1. Vinyl coating 2, into a prefabricated monolithic stock (e.g. figure 2 ), and then superimpose two single-piece materials on each other, and fuse them together under high temperature and pressure to become the final multi-composite engineering cloth (such as figure 1 ).

[0051] First of all, according to different use occasions, different braided layers with fibers or non-woven fabrics are selected as the base layer 1. Among them, the braided layers with fibers include glass fiber woven cloth, chemical fiber woven cloth, etc. According to different uses, examples focus on fire prevention, high Different tire base layers are selected for streng...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com