Eavcuation valve control device

A valve control and vacuum pumping technology, applied in the direction of fluid pressure control, non-electric variable control, control/regulation system, etc., can solve the problems of particle reduction and particle shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention. Those of ordinary skill in the relevant technical field can also make various changes and modifications without departing from the spirit and scope of the present invention. Therefore All equivalent technical solutions also belong to the category of the present invention, and the scope of patent protection of the present invention should be defined by each claim.

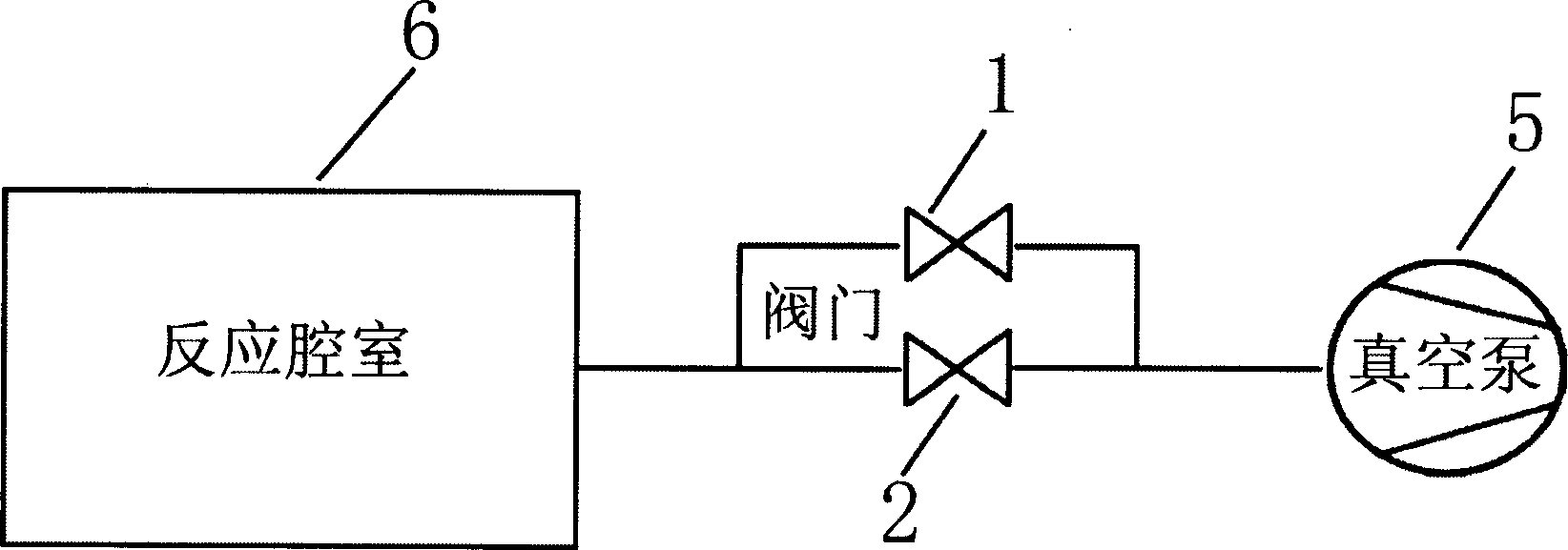

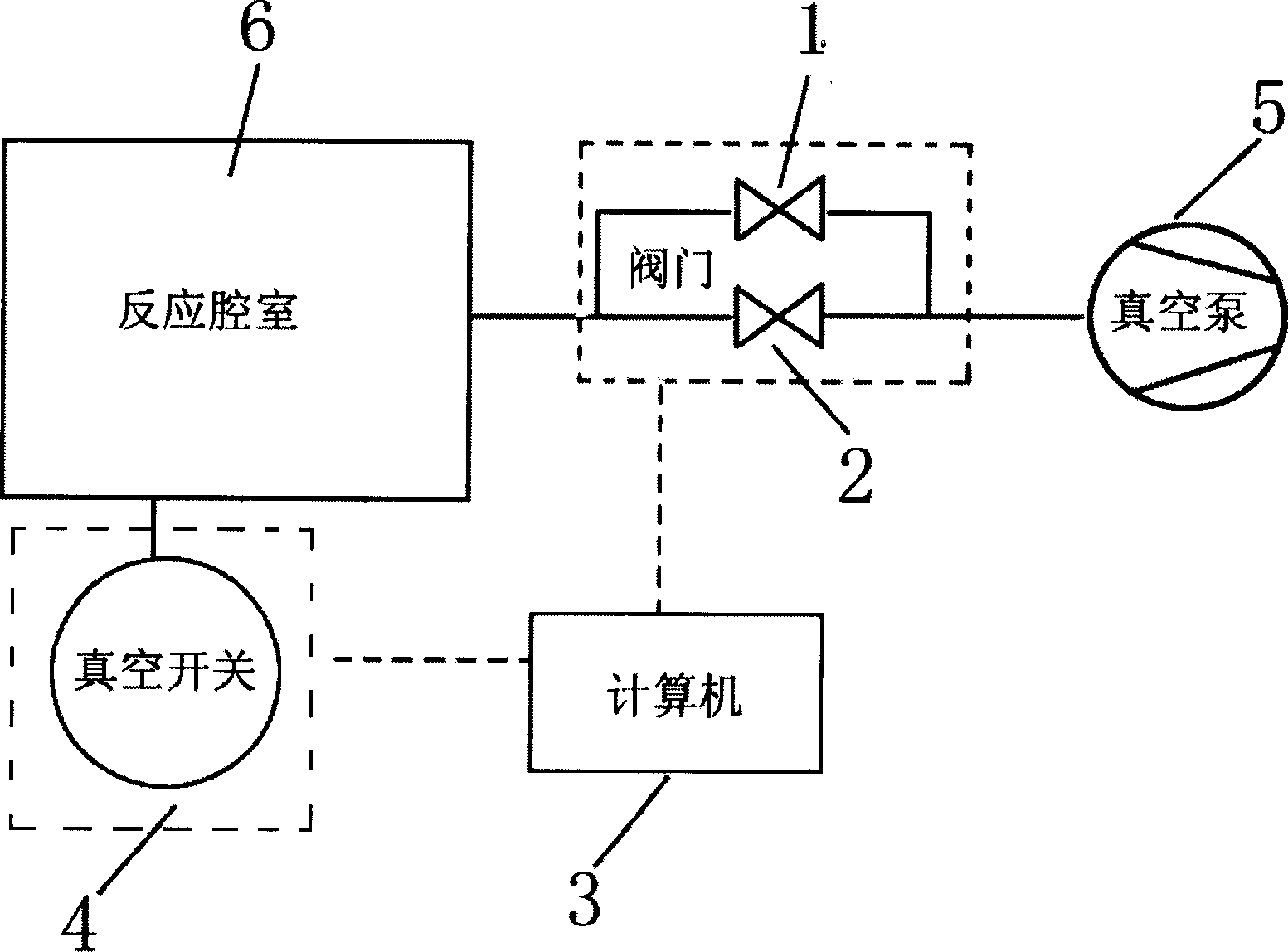

[0018] A vacuum valve control device, using 6LVV-DPFR4-C bypass valve 1, LPJ1-40 model isolation valve 2 and CPCI3700A industrial computer as valve control unit 3, bypass valve 2 and isolation valve 3 are connected in parallel to vacuum pump model 5 Between the chamber 6 and the vacuumed chamber, the valve control unit 3 controls the closing of the valves 1 and 2, and a vacuum switch 4 is also provided. The vacuum switch 4 detects the pressure of the vacuumed chamber 5 and comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com