Direct-coupling substrate integrated wave-guide circular cavity wave-filter

A technology that integrates waveguides and circular cavities on a substrate, which is applied to waveguide-type devices, electrical components, circuits, etc., can solve the problems of bulky, high cost, and difficult to integrate, and achieve the effect of small size, low cost, and good integration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

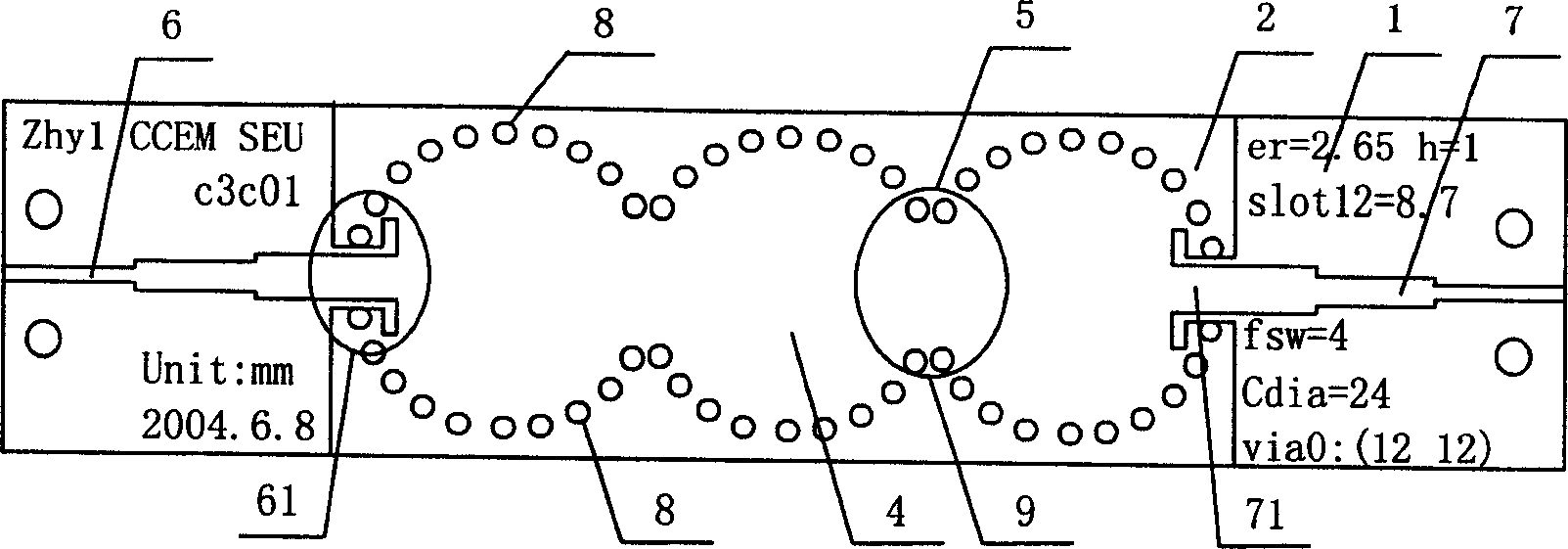

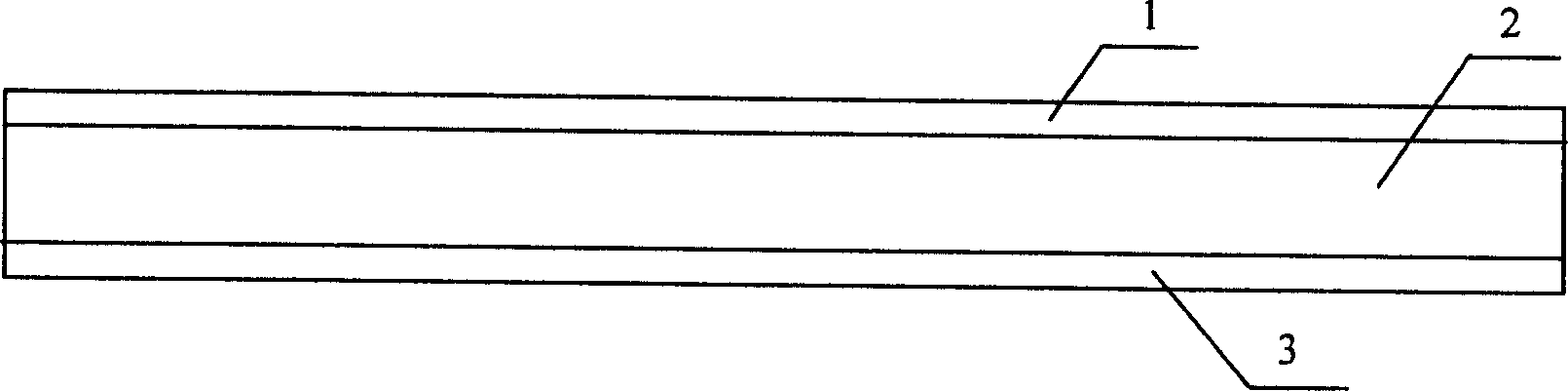

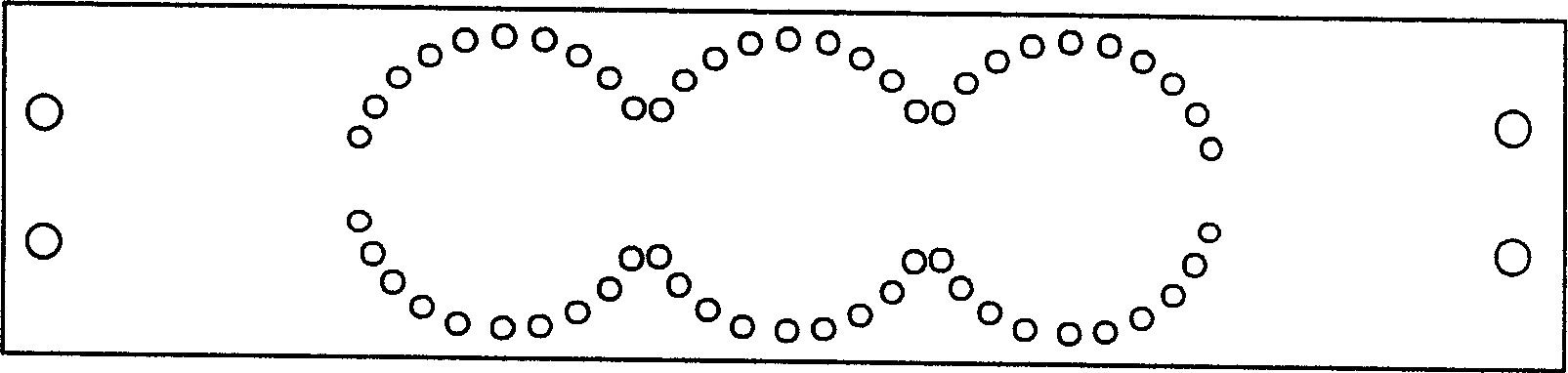

[0019] A direct-coupled substrate-integrated waveguide circular cavity filter for filtering, comprising a dielectric substrate 1 with metal patches 2 and 3 on both sides, and a substrate-integrated waveguide on the dielectric substrate 1 The circular cavities 4 are coupled through waveguides 5 between the substrate-integrated waveguide circular cavities, and the substrate-integrated waveguide circular cavities 4 on both sides are respectively connected with microstrip lines 6 and 7. The chip integrated waveguide circular cavity 4 is composed of metallized through-holes 8 arranged on the dielectric substrate 1 and arranged in a circle. The waveguide 5 is composed of two rows of metallized through-holes 9. Open a through hole on the substrate, set a metal sleeve 10 on the wall of the through hole and connect the metal sleeve with the metal patches covering both sides of the dielectric substrate. In this embodiment, the microstrip lines 6 and 7 pass through the coplanar The waveg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com