Oil pipe preheating and washing system

A cleaning system and oil pipe technology, applied in the direction of electric heating devices, cleaning hollow objects, cleaning methods and appliances, etc., can solve the problems of high operating costs, harsh working conditions, high total power, etc., and achieve reduced labor intensity, high mechanization, and cleaning The effect of quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

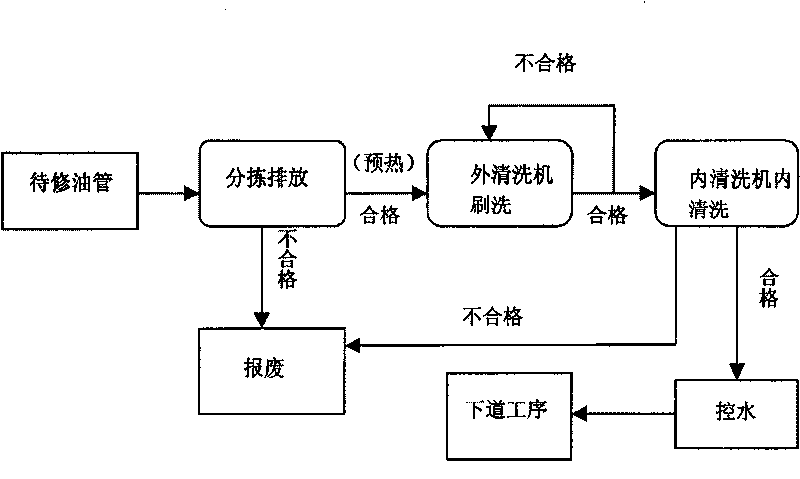

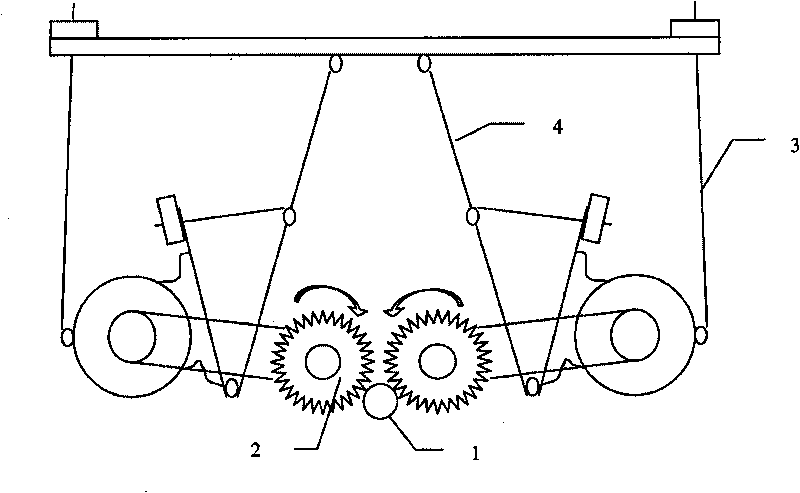

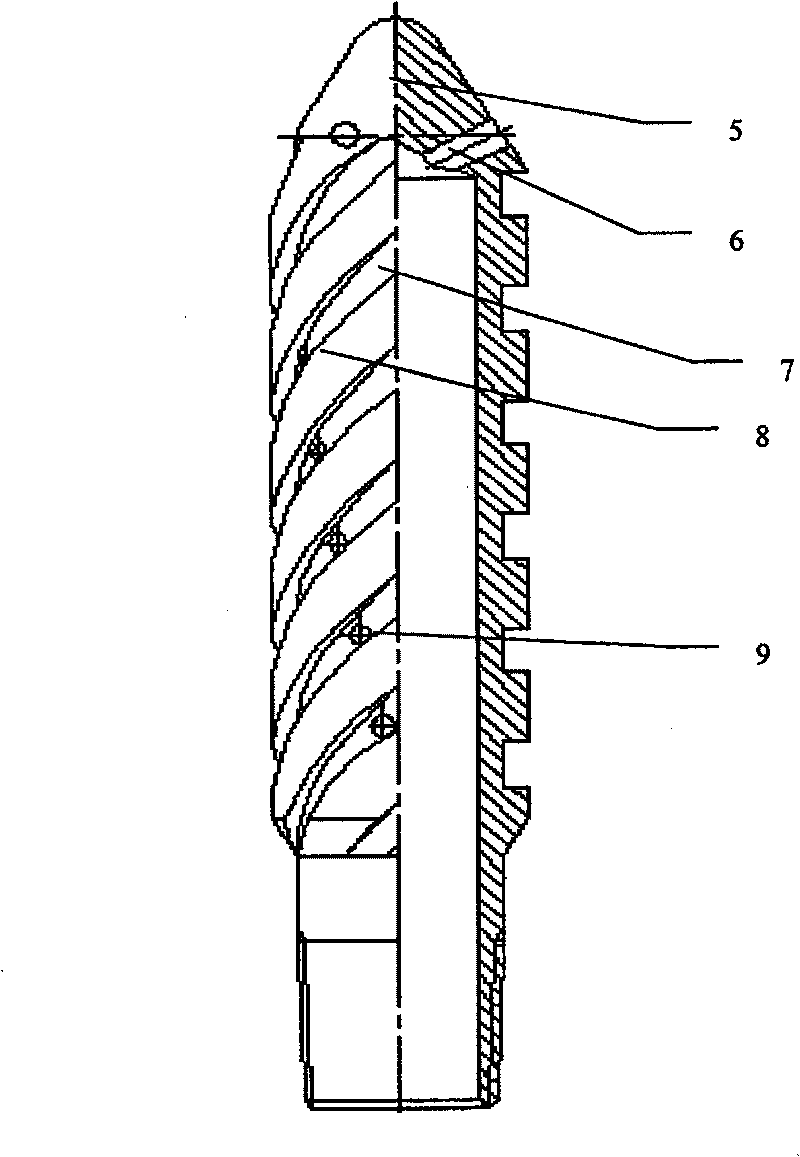

[0018] The present invention is described in further detail below in conjunction with embodiment: see appendix figure 1 , the oil pipe preheating cleaning system includes an external cleaning machine and an internal cleaning machine, and is also equipped with a far-infrared heating device. This system can also be used for cleaning other tubular objects. It sorts the oil pipes 1 to be cleaned and discharges them in the same direction. When the ambient temperature is lower than 18°C, the oil pipe 1 is preheated and heated, and the oil pipe 1 is cleaned by the external cleaning machine and the internal cleaning machine; when the ambient temperature is higher than 18°C, the oil pipe 1 is directly cleaned by the external cleaning machine and the internal cleaning machine. Cleaning. Preheating is to use the far-infrared heating device to preheat the oil pipe 1 before cleaning, which is beneficial to the removal of oil stains. See the attached figure 2 , the outer washing machine co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com