Machine for grinding optical workpieces, in particular plastic eyeglass lenses

一种光学工件、机加工的技术,应用在光学元件、光学元件、金属加工机械零件等方向,能够解决大成本等问题,达到短机加工时间、高形状精度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

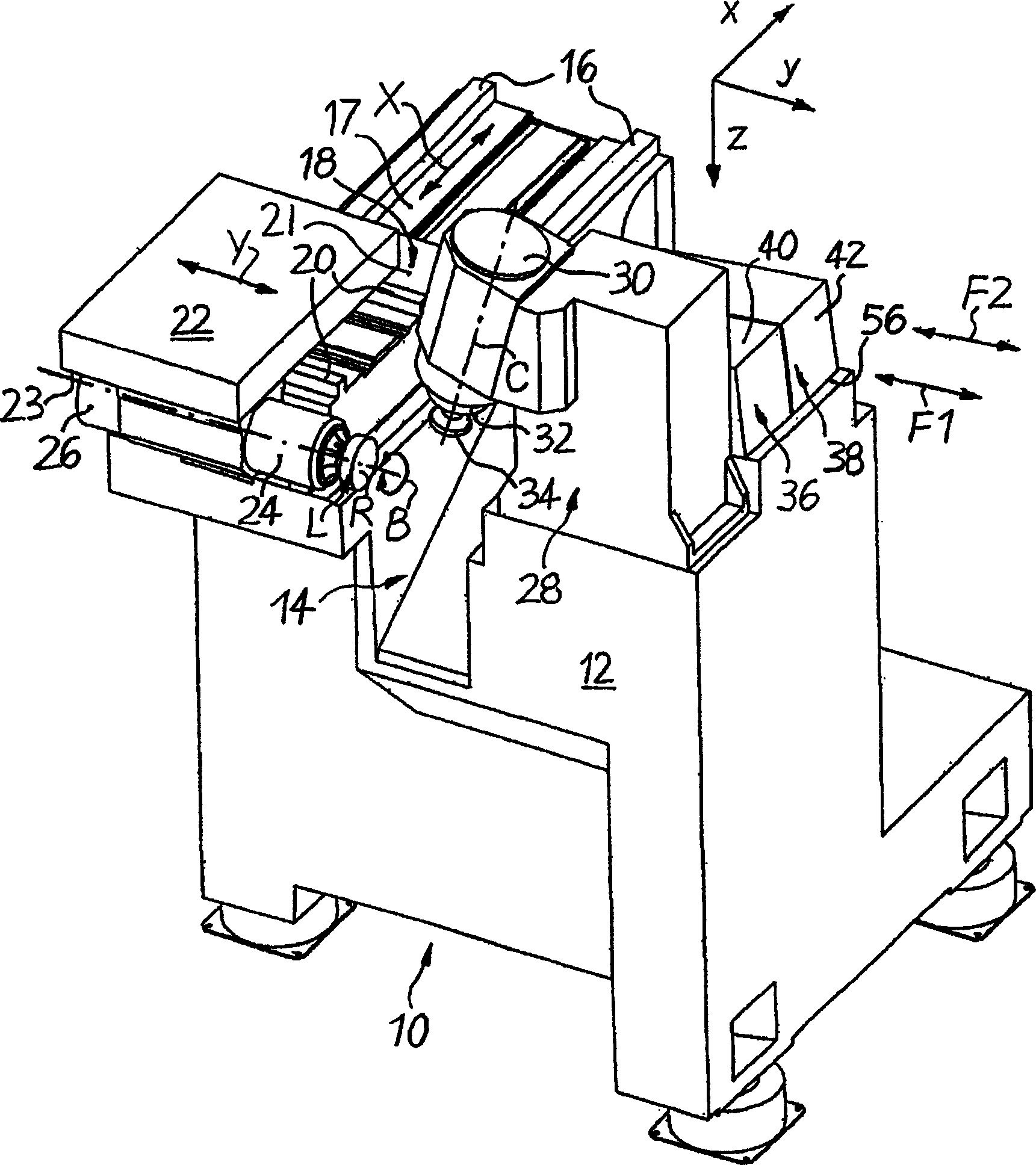

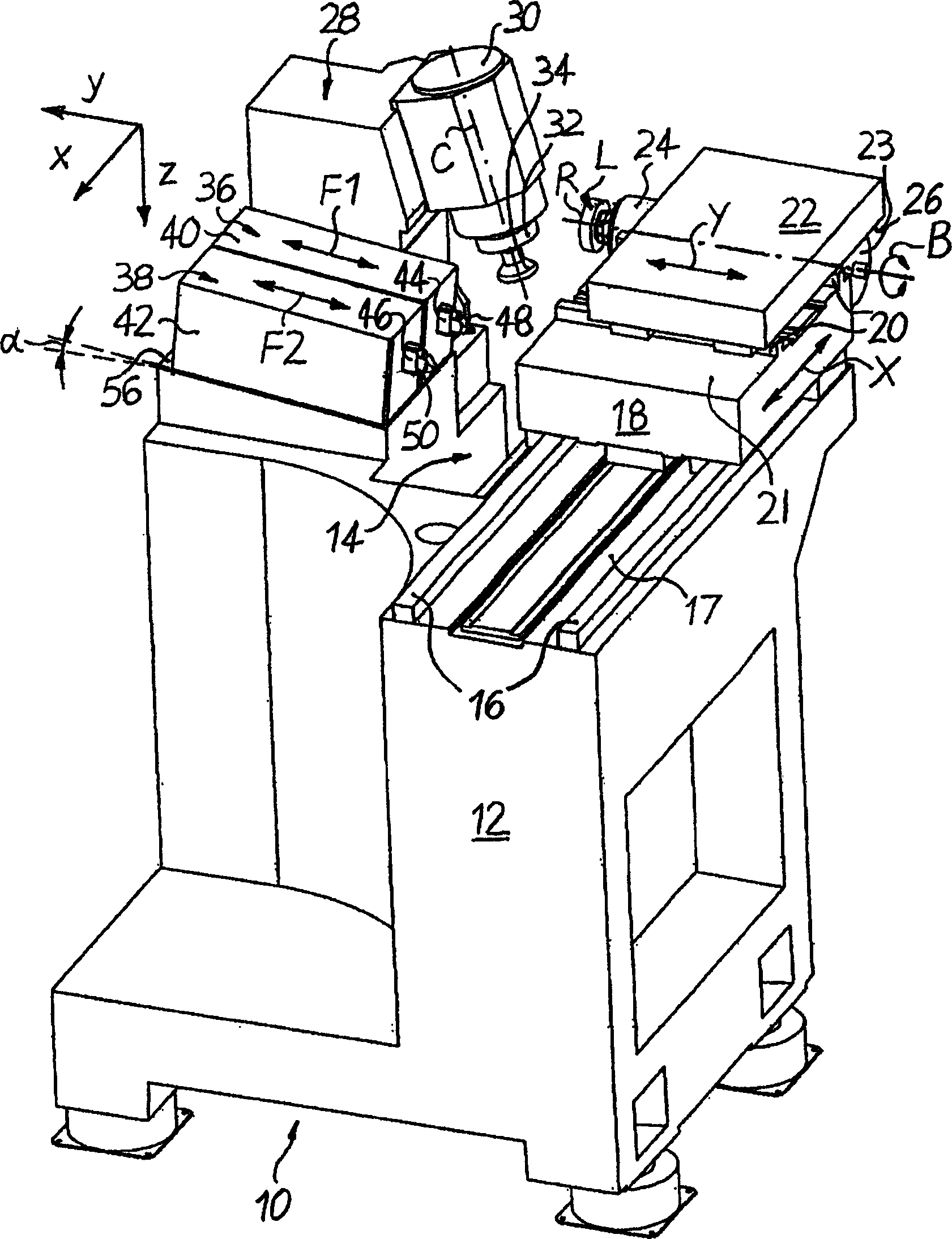

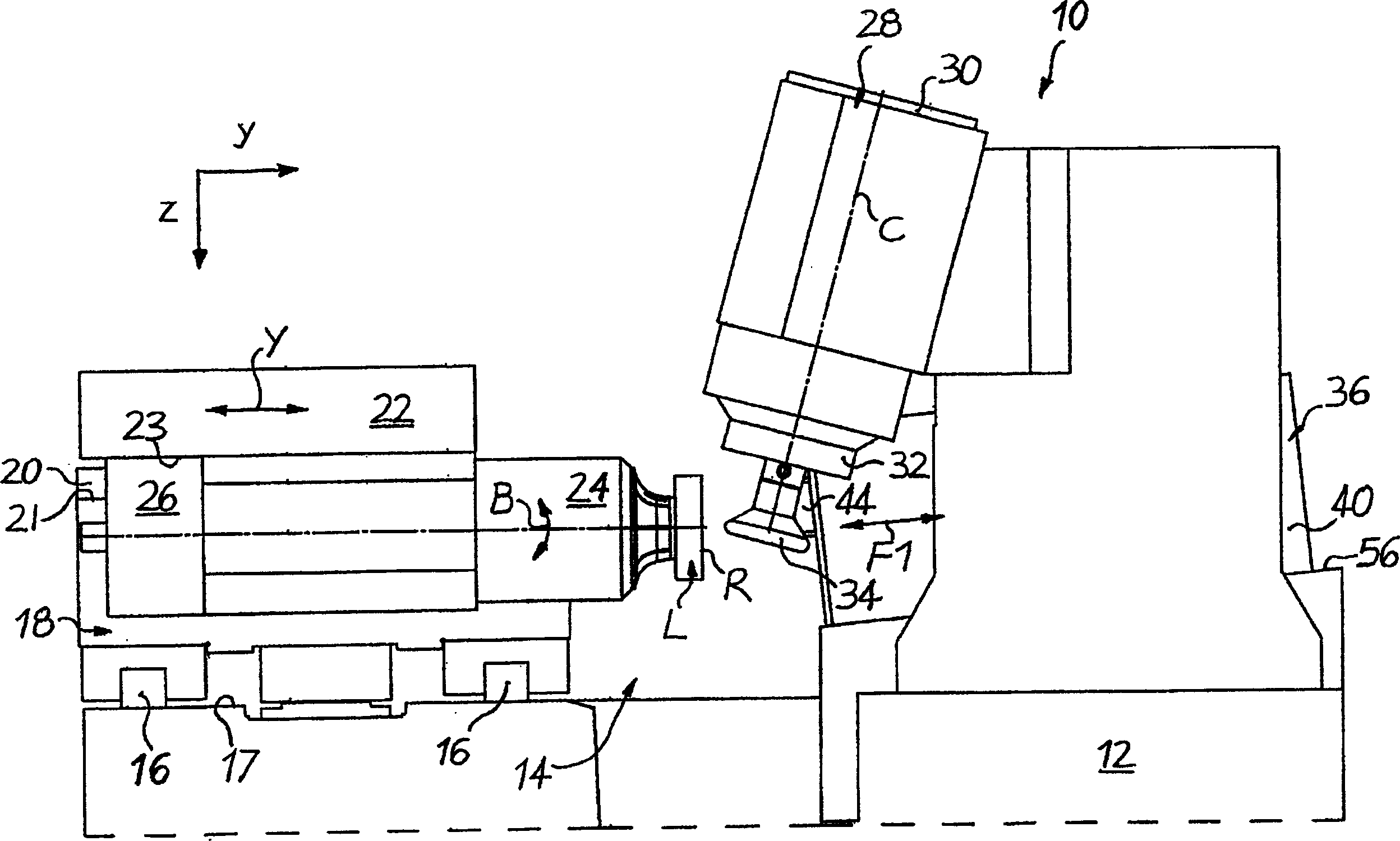

[0023] Figures 1 to 5 A CNC-controlled machine tool 10, in particular for machining the surface of a plastic ophthalmic lens L, is schematically shown in a Cartesian coordinate system, where the lowercase letters x, y, and z represent the width direction of the machine 10 (x ), the length direction (y) and the height direction (z).

[0024] like Figures 1 to 5 As shown, machine tool 10 includes a frame 12 defining a machining area 14 . exist figure 1 fixed on the left-hand side of the machining area 14, in figure 1 On the upper mounting surface 17 of the frame 12 are two guide rails 16 extending parallel to each other in the (horizontal) width direction x. Mounted movably on rail 16 is an X slide adjustable in both directions of the X axis in a CNC controlled positioning manner by associated CNC drive and control elements (not shown).

[0025] exist figure 1 Two further guide rails 20 extending parallel to each other in the (likewise horizontal) length direction y and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com