High rigidity riding vehicle rear axle

A high-stiffness technology for passenger cars, applied to vehicle components, interconnection systems, suspensions, etc., can solve the problems of losing the coaxiality of the trailing arm shaft tube, affecting the driving performance of the vehicle, and poor strength and stiffness. Achieve the effect of improving vehicle driving performance, increasing rigidity and strength, and reducing materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

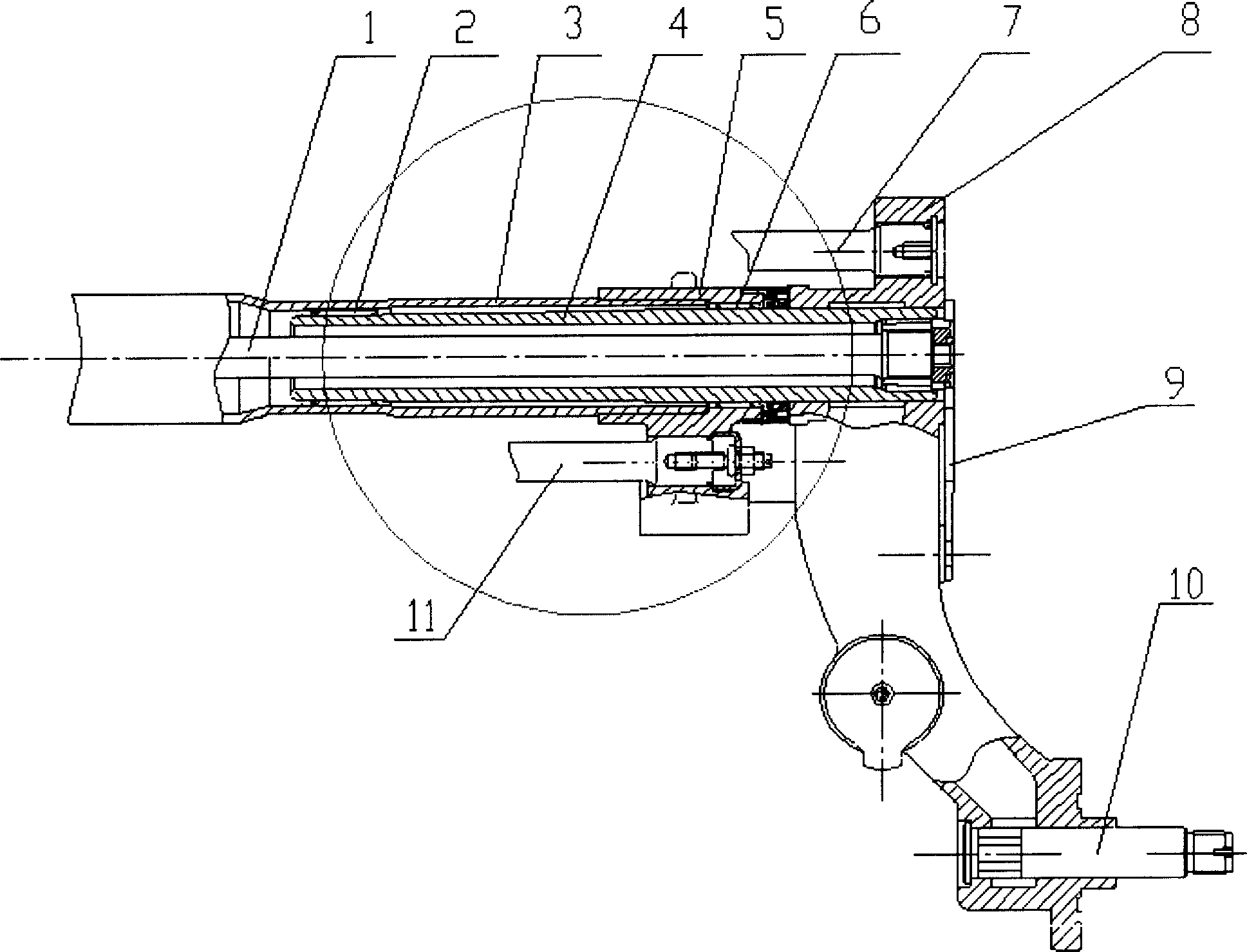

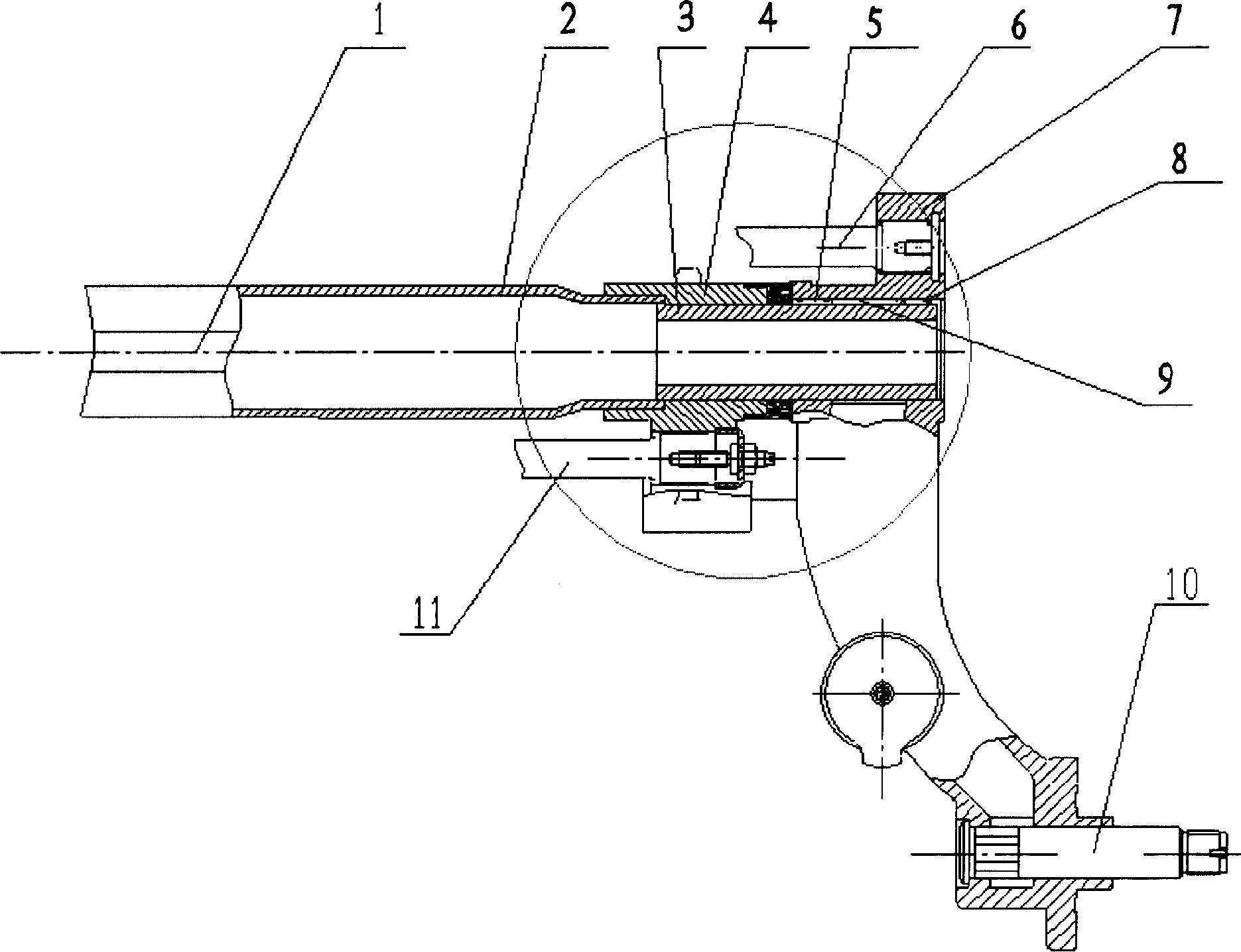

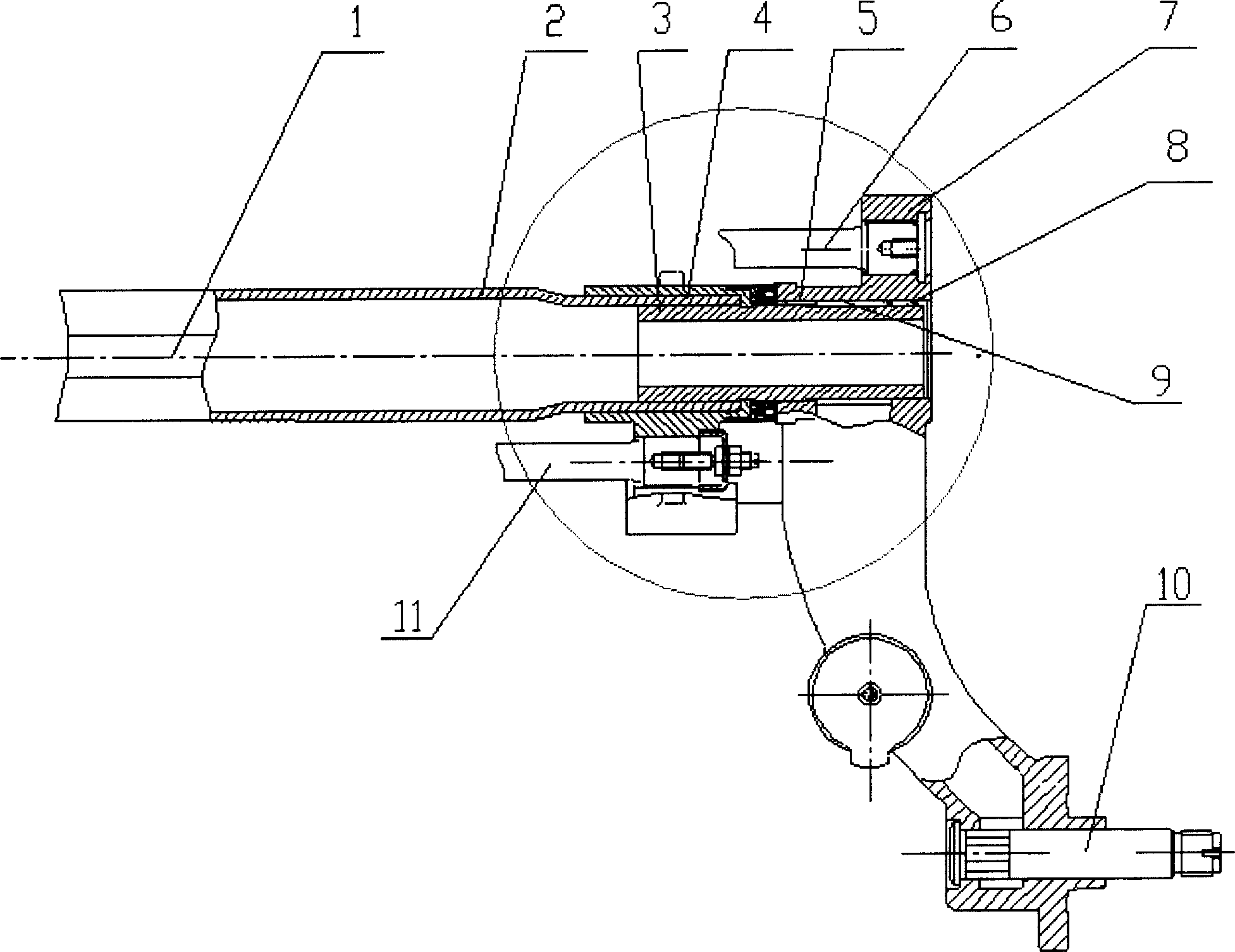

[0025] The high-rigidity rear axle structure of the present invention is such as image 3 As shown, it is composed of stabilizer bar (1), rear axle shaft tube (2), trailing arm shaft tube (3), bracket (4), front torsion bar (6), inner bearing (5), spacer (9) ), outer bearing (8), trailing arm (7), hub axle (10) and rear torsion bar (11); its stabilizer bar can be built-in (in the rear axle tube (2)) or External (outside the rear axle shaft tube (2)); among them, the rear axle shaft tube (2), the trailing arm shaft tube (3) and the bracket (4) are tightly connected into one body; the inner and outer needle roller bearings (5) , 8) Move to the trailing arm (7); the outer bearing (8) of the trailing arm shaft tube (3) adopts an integral outer ring.

[0026] The specific method steps of its processing and assembly are as follows:

[0027] 1. According to the requirements of different rear axles, the two ends of the rear axle tube (2) are reduced in diameter according to a certain lengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com