Hydrophilic and phydrophobic mode sheet base special for biological chip

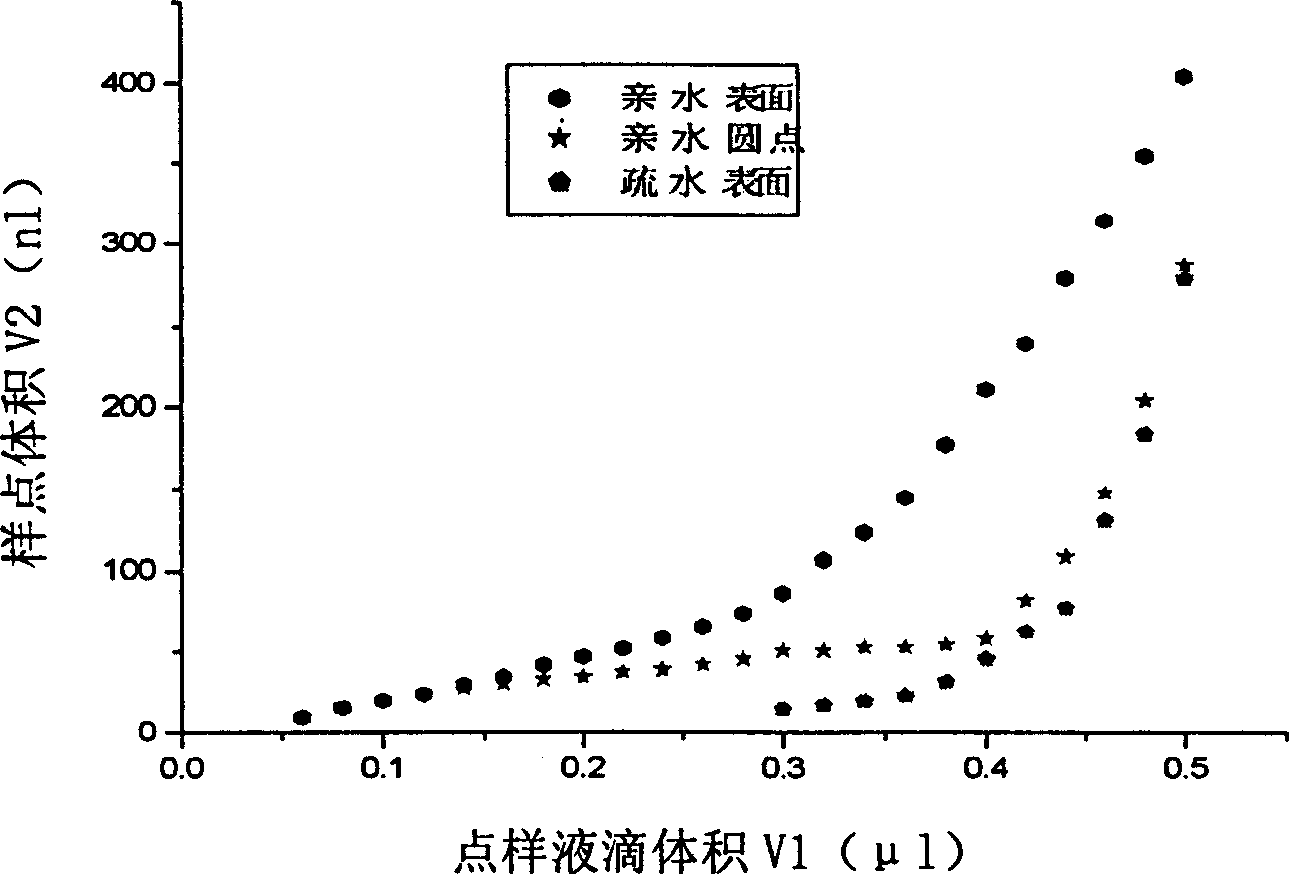

A biochip, hydrophilic and hydrophobic technology, applied in the direction of biological testing, microbial measurement/inspection, biochemical equipment and methods, etc., can solve the problems of high array points, cross-contamination of sample points, large spot area, etc., and achieve area consistency High, reduce production difficulty, avoid cross-contamination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

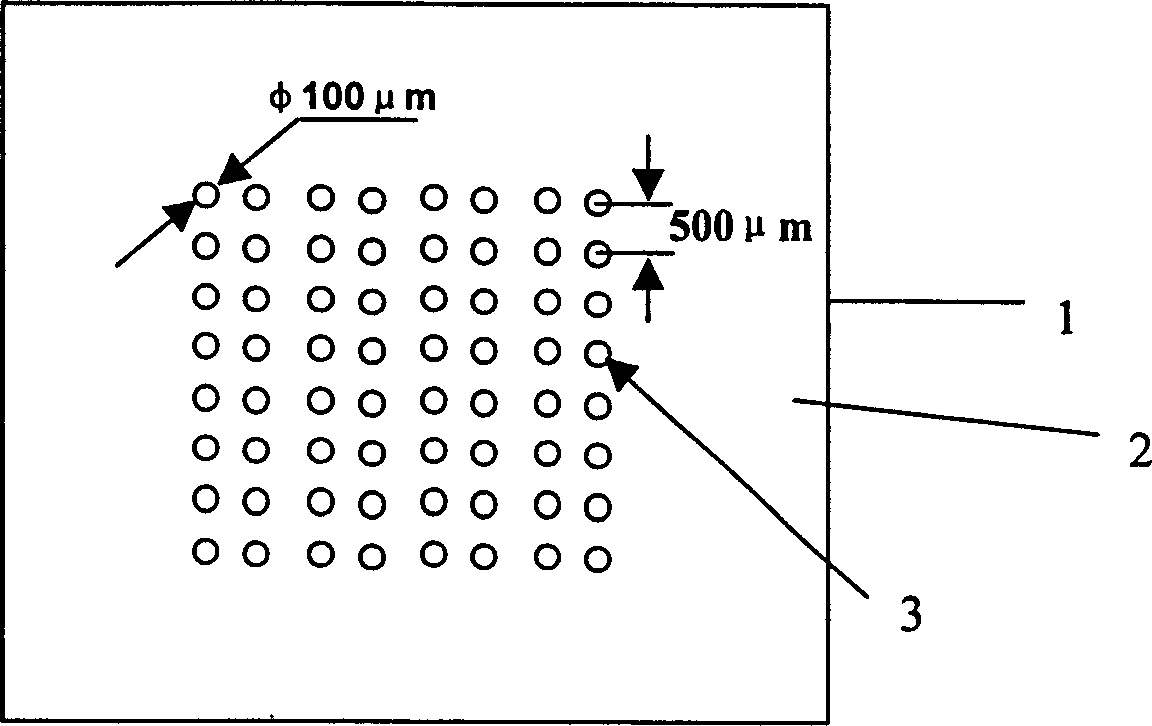

[0018] see figure 1 , the embodiment of the present invention is provided with a rectangular substrate 1, the upper surface of the substrate 1 is provided with a hydrophobic layer 2, and an array of hydrophilic dots 3 is arranged on the hydrophobic layer 2, and the diameter of the hydrophilic dots 3 is 10 to 500 μm. The center distance between the water dots 3 is 50-1000 μm, the substrate 1 is selected from glass slides or silicon wafers, etc., the hydrophobic layer is selected from polydimethylsiloxane (PDMS), the thickness is 2-5 μm, and the hydrophilic dot film The material of the layer is made of hydrophilic metal (iron, aluminum), and the thickness is 1-3 μm. The contact angle of the hydrophilic surface in the prepared film base is 56°, and the contact angle of the hydrophobic surface is 110°.

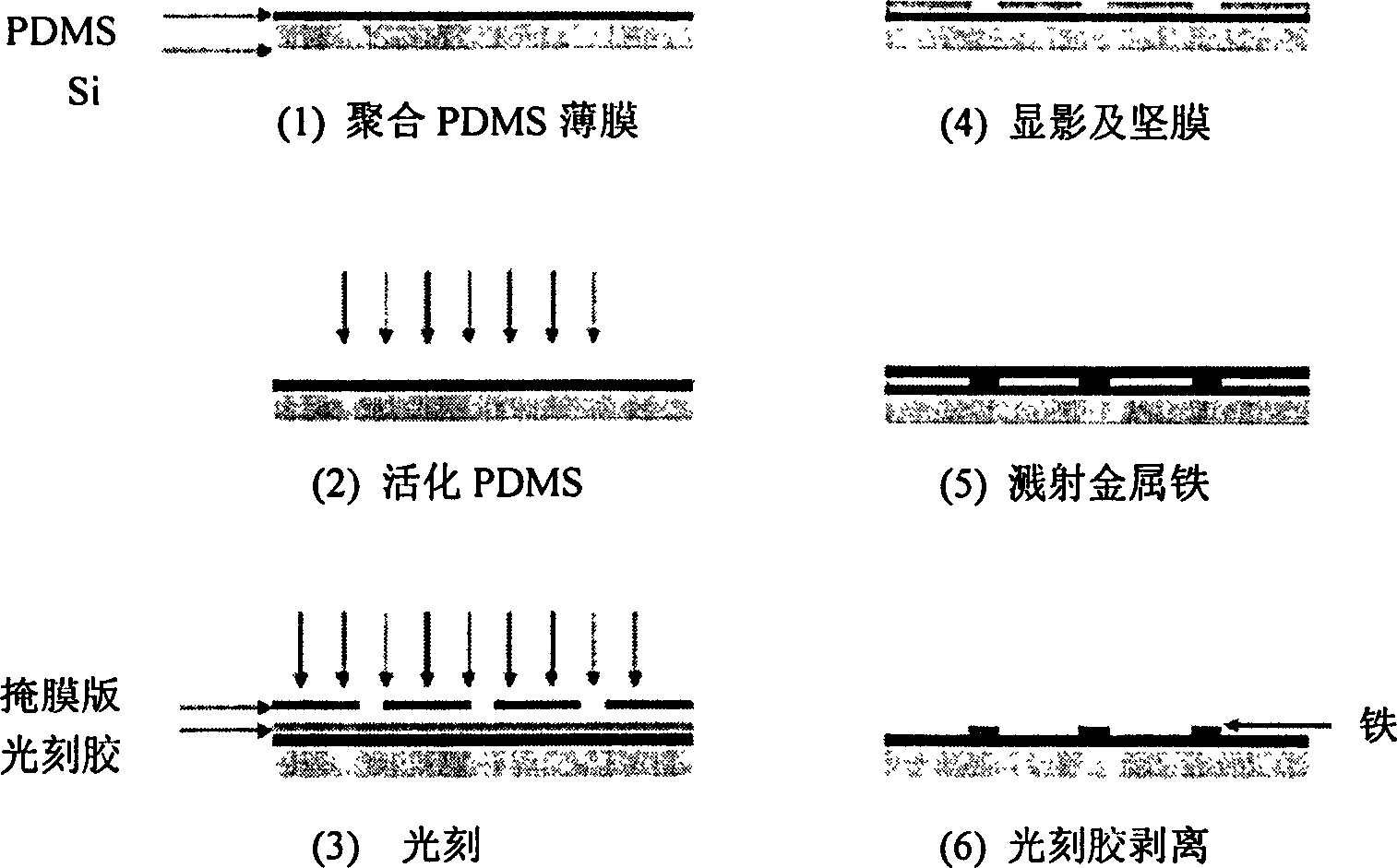

[0019] A kind of preparation method of the special-purpose hydrophilic-hydrophobic mode sheet base of biochip of the present invention is given below (there can be many ways to c...

Embodiment 2

[0032] Similar to Example 1, the difference is that a circular base is used, the thickness of the hydrophobic layer provided on the upper surface of the base is 3-5 μm, and an array of hydrophilic square points is arranged on the hydrophobic layer, and the length and width of the hydrophilic square points are equal. is 100 μm, and the center-to-center distance between hydrophilic square points is 800 μm. The substrate is a slide glass with a size of 2.5cm×7.5cm, and the material of the film layer of the hydrophilic square dots is aluminum and hydrophilic metal.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com