Pseudoproof container and its mfg. method and forming apparatus

A container and container body technology, applied in chemical instruments and methods, bottles, luminescent materials, etc., can solve the problems of backward anti-counterfeiting technology, difficult process, easy to be destroyed, etc., and achieve improved reliability, non-destructive, anti-counterfeiting features Significant, range-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

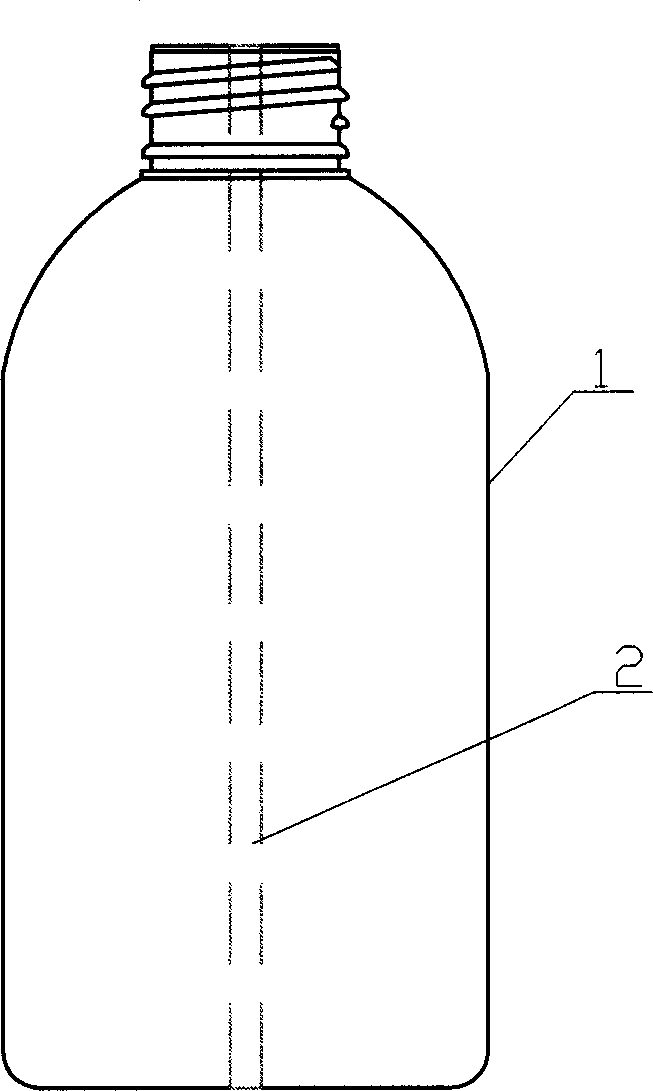

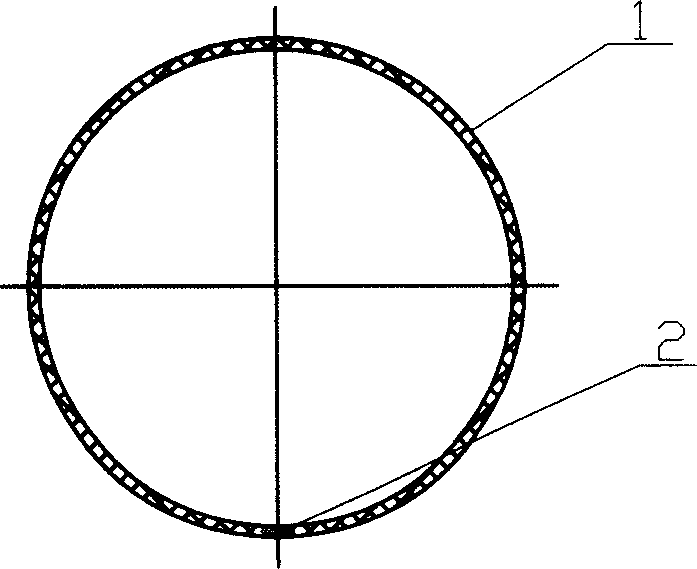

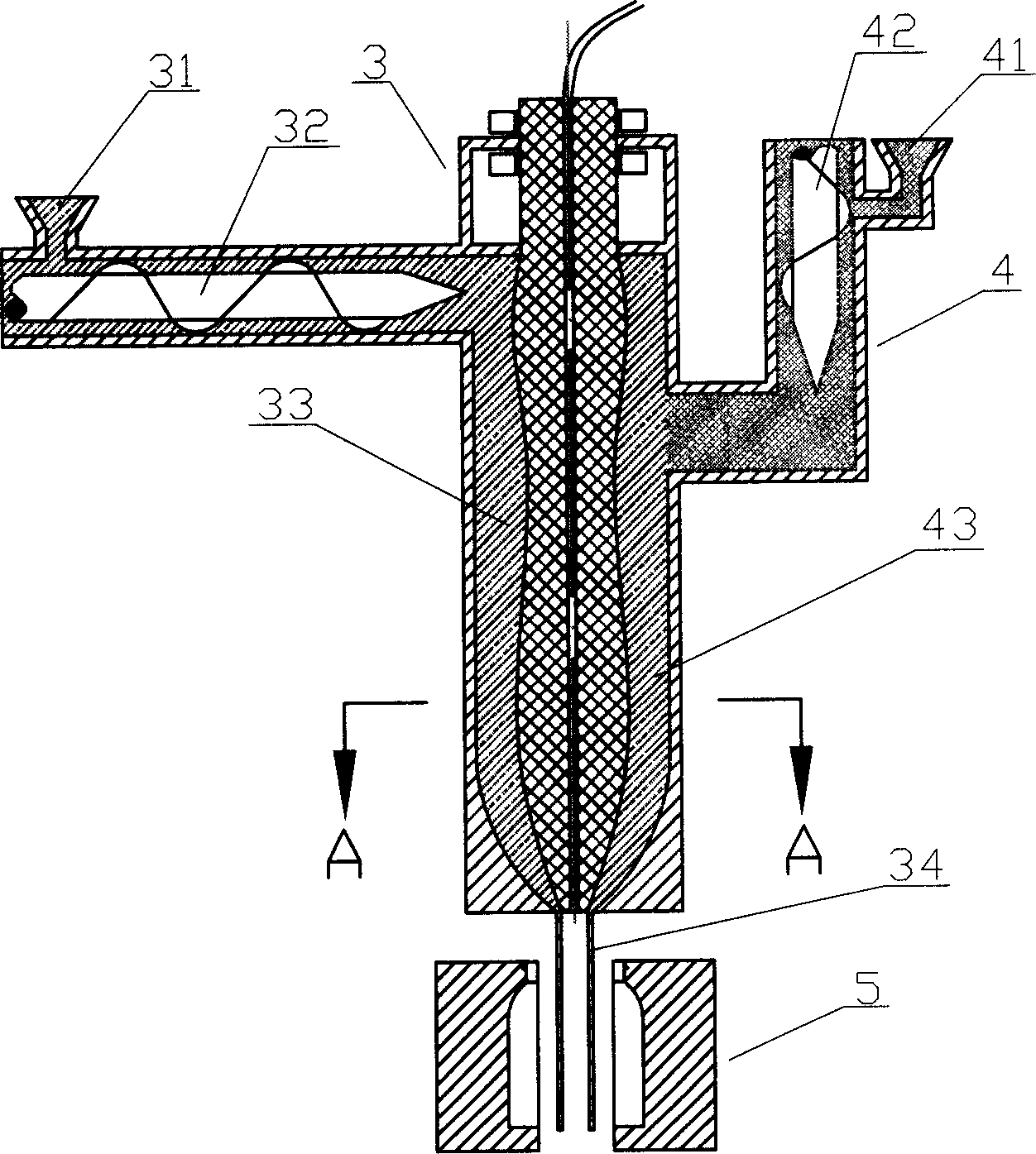

[0022] Such as Figure 1 ~ Figure 2 As shown, the anti-counterfeiting container of the present invention includes a plastic extrusion or injection molding blow molding container body 1, wherein at least one side wall or bottom of the container body 1 is integrally extruded or injection molded with at least one The anti-counterfeiting mark part 2 has a pattern or character or a combination thereof that can be invisible under sunlight but can display special luster under ultraviolet light. Wherein the above-mentioned anti-counterfeit marking part 2 is a fluorescent color material mixed with the main material of the container body 1 and fluorescent color particles that are compatible with the main material of the container body 1 and are the same color as the main body color particles of the container body 1, the fluorescent color material Synchronous extrusion blow or injection molding of the main color material composed of the raw material of the container body 1 and the main c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com