Preparation process of post vulcanization agent dihydrated hexa methylene 1.6-disodium dithiosulfate

A technology of disodium dithiosulfate and hexamethylene dihydrate is applied in the fields of synthesis of new post-vulcanization stabilizers, separation and purification of products, and can solve problems such as products that do not meet requirements, achieve easy operation and avoid using , the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

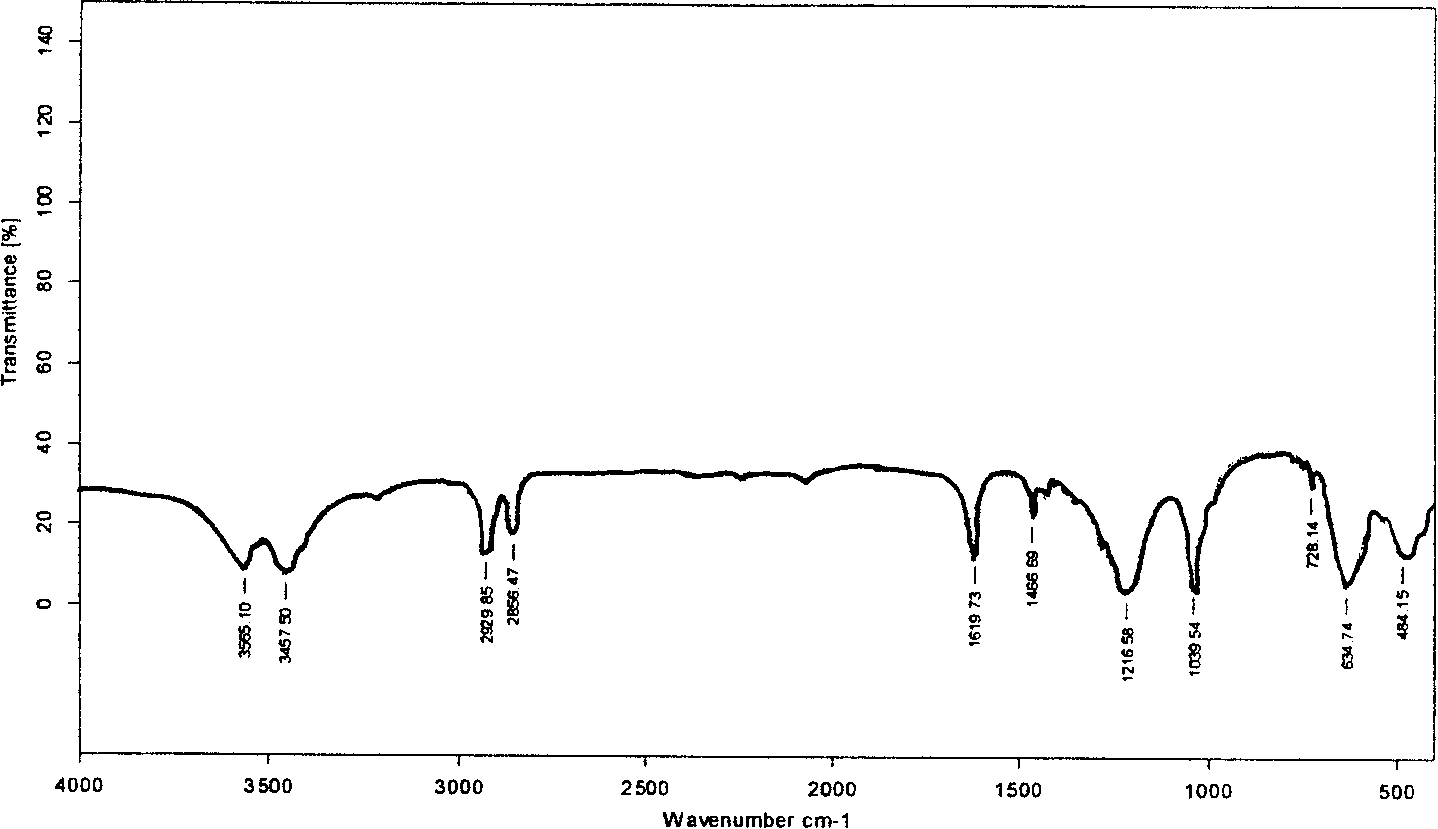

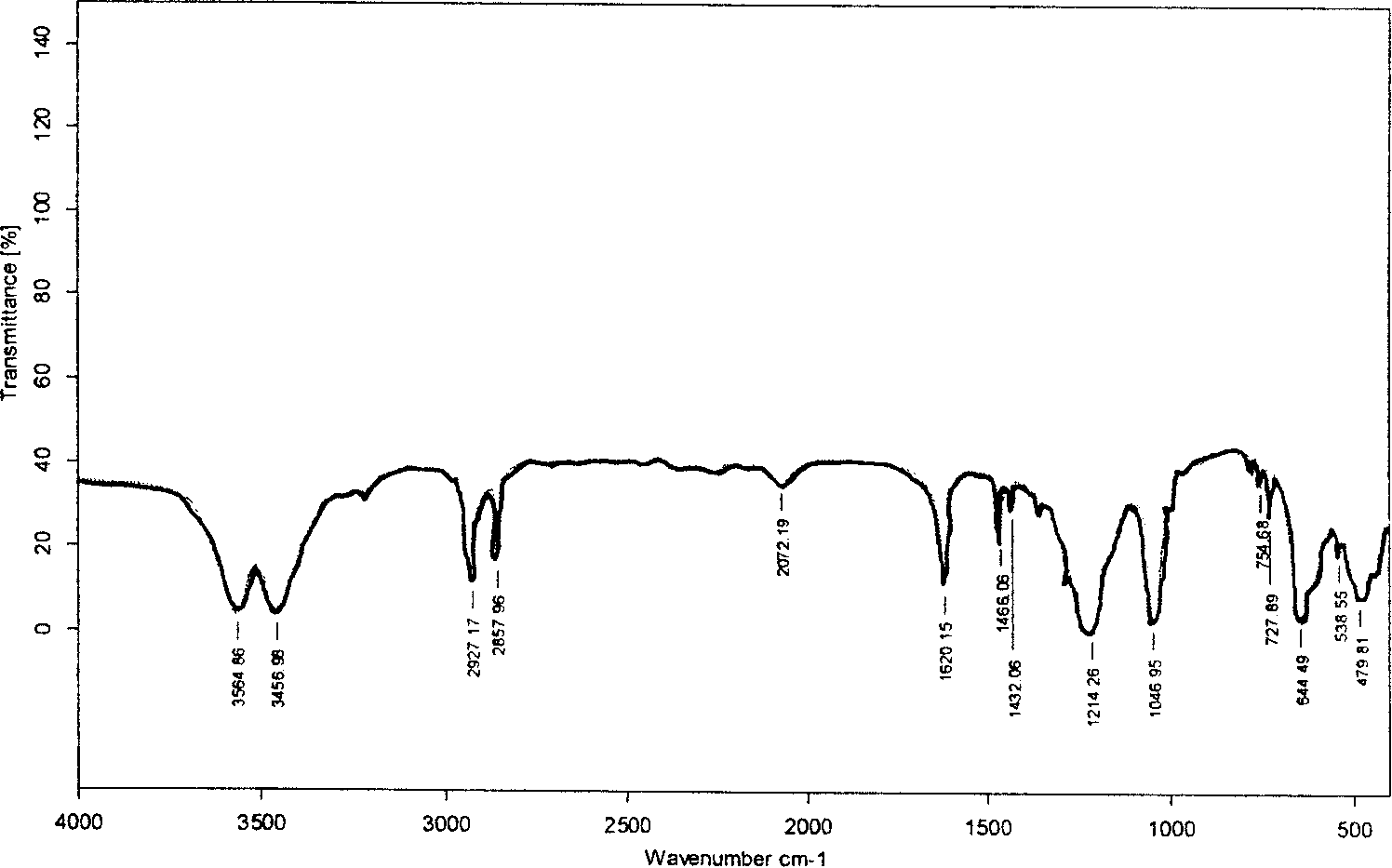

Image

Examples

Embodiment 1

[0016] Weigh 20g of sodium thiosulfate, measure 6mL of dibromohexane into a three-necked flask, add 80mL of 50% ethanol, and react at 60°C to 80°C for 15 to 60min under reflux and stirring conditions.

[0017] After the reaction, add 110mL of 95% ethanol to the reaction solution, reflux at 80°C for 15 minutes and then filter while it is hot. After adding an appropriate amount of tap water to the filtrate, let it cool down gradually, and the product crystallizes out during the cooling process.

[0018] After the obtained product is dried, it becomes the final vulcanizing agent dihydrate hexamethylene 1,6-dithiosulfuric acid disodium salt.

[0019] The result of component analysis of the finished product: the sodium chloride content is less than 0.84%, and the active ingredient content is greater than 97.80%. (The standard used by enterprises is that the sodium chloride content is less than 1%, and the active ingredient content is greater than 95%)

Embodiment 2

[0021] Take 54.6g, 0.35mol of 1,6-dichlorohexane and 163.4g, 0.75mol of sodium thiosulfate and dissolve them in 230mL of water and 230mL of 95% ethanol, and react in the reactor for 6-15min, with the temperature controlled at 90-135 ℃.

[0022] After the reaction, add 900mL of 95% ethanol to the reaction solution, reflux at 80°C for 15 minutes and then filter while it is hot. Then add an appropriate amount of tap water to the filtrate, and then let it cool down gradually. During the cooling process, the product will crystallize.

[0023] After the obtained product is dried, it becomes the final vulcanizing agent dihydrate hexamethylene 1,6-dithiosulfuric acid disodium salt.

[0024] The result of component analysis of the finished product: the sodium chloride content is less than 0.52%, and the active ingredient content is greater than 98.95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com