Method for extracting astaxanthin through ionic liquid-salt aqueous two-phase system

A two-phase system, ionic liquid technology, applied in the direction of organic chemistry, etc., can solve the problems of high operating pressure of astaxanthin, oxidative decomposition of astaxanthin, easy volatilization of organic solvents, etc., to achieve strong thermochemical stability, biological phase Capacitive and environmentally friendly effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

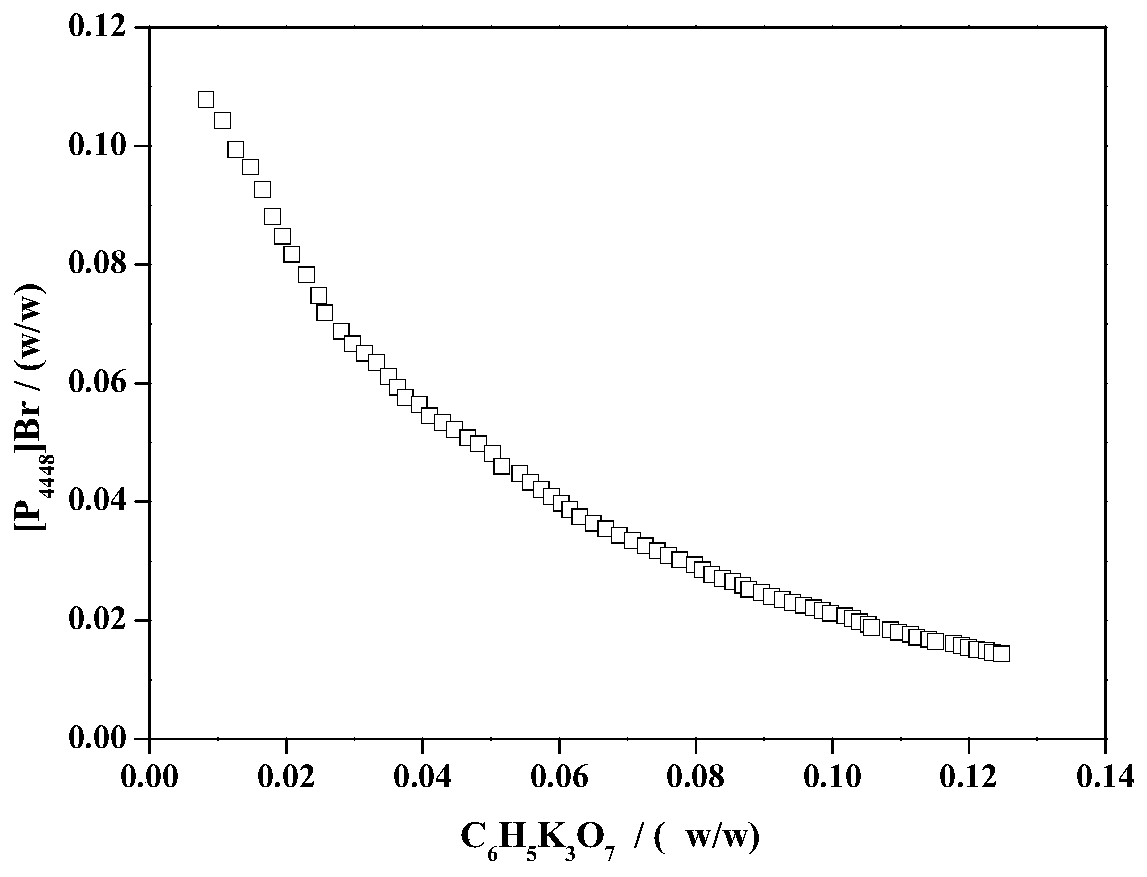

[0053] (1) The ionic liquid tributyl octyl phosphine bromide and distilled water are mixed uniformly to prepare an ionic liquid aqueous solution, so that the mass fraction of tributyl octyl phosphine bromide in the ionic liquid aqueous solution is 2%.

[0054] (2) Wash the fresh shrimp shells and freeze-dry them at -50°C for 40 hours, then grind them in a grinder, and pass through a 50-mesh sieve to obtain shrimp shell powder for later use.

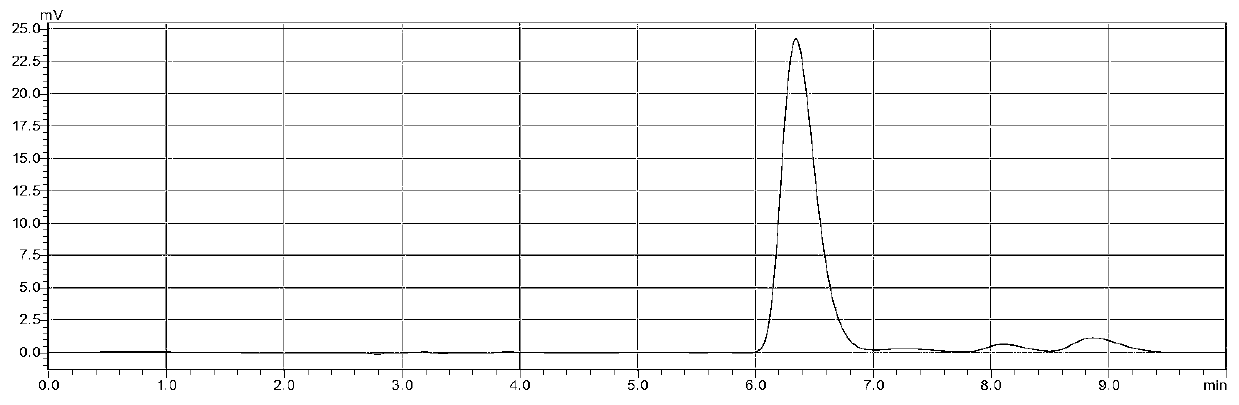

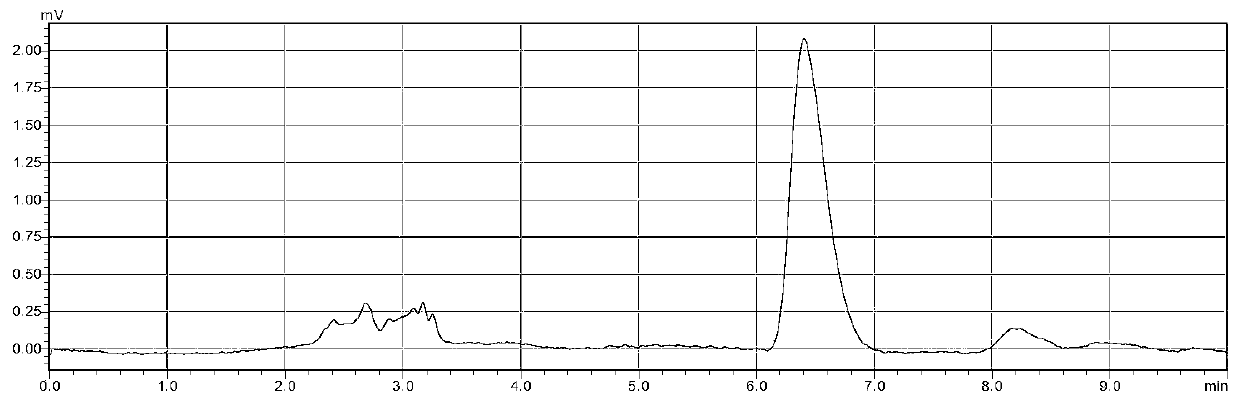

[0055] (3) Get the shrimp shell powder that 1g step (1) obtains and the ionic liquid aqueous solution that 35g step (2) obtains and place in the beaker, then adopt magnetic stirrer to stir, set stirring speed to be 1000rpm, stir 60min at room temperature, Then the obtained mixture was centrifuged at a centrifugal speed of 5000rpm for 20min to obtain the supernatant of the ionic liquid aqueous solution from which astaxanthin was extracted and the shrimp shell powder precipitate of astaxanthin, and the supernatant was collected to obtain ast...

Embodiment 2

[0059] (1) The ionic liquid tributyloctylphosphine bromide and distilled water are mixed uniformly to prepare an ionic liquid aqueous solution, so that the mass fraction of tributyloctylphosphine bromide in the ionic liquid aqueous solution is 5%; wherein, the ionic liquid is three Butyloctylphosphine bromide.

[0060] (2) Wash the fresh shrimp shells and freeze-dry them at -55°C for 40 hours, then grind them in a grinder, and pass through a 70-mesh sieve to obtain shrimp shell powder for later use.

[0061] (3) Get 1g of the shrimp shell powder obtained in step (1) and the aqueous ionic liquid solution obtained in 30g of step (2) in a beaker, then use a magnetic stirrer to stir, set the stirring speed to 500rpm, and stir at room temperature for 120min. Then the obtained mixture was centrifuged at a centrifugal speed of 6000rpm for 18min to obtain the supernatant of the ionic liquid aqueous solution from which astaxanthin was extracted and the shrimp shell powder precipitate o...

Embodiment 3

[0065] (1) The ionic liquid tributyl octyl phosphine bromide and distilled water were uniformly mixed to prepare an ionic liquid aqueous solution, so that the mass fraction of tributyl octyl phosphine bromide in the ionic liquid aqueous solution was 8%.

[0066] (2) Wash the fresh shrimp shells and freeze-dry them at -60°C for 30 hours, then grind them in a grinder, and pass them through an 80-mesh sieve to obtain shrimp shell powder for later use.

[0067] (3) Get the shrimp shell powder that 1g step (1) obtains and the ionic liquid aqueous solution that 25g step (2) obtains and place in the beaker, then adopt magnetic stirrer to stir, setting stirring speed is 800rpm, stir 80min at room temperature, Then the obtained mixture was centrifuged at a centrifugal speed of 6000rpm for 18min to obtain the supernatant of the ionic liquid aqueous solution from which astaxanthin was extracted and the shrimp shell powder precipitate of astaxanthin, and the supernatant was collected to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com