Oil containing bearing end cover of fan motor for air conditioner

A technology for bearing end covers and fan motors, which is applied to bearing components, shafts and bearings, casings/covers/supports, etc., can solve the problems of affecting the quality of motors and air conditioners, expensive processing costs, and high product defect rates, and achieve improvement Product competitiveness, simple processing and assembly, and good workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

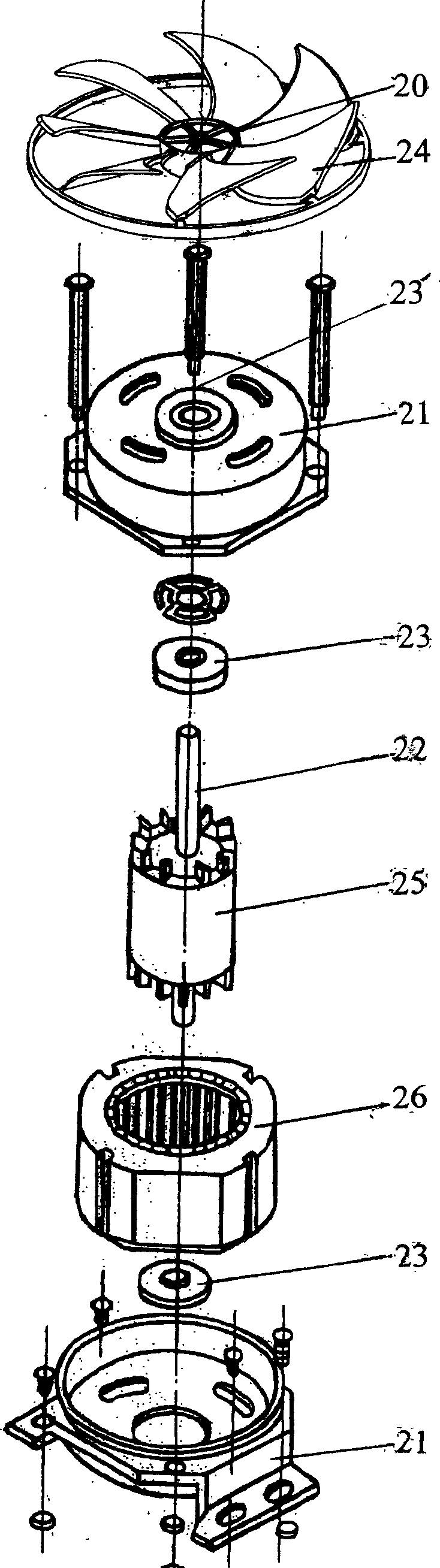

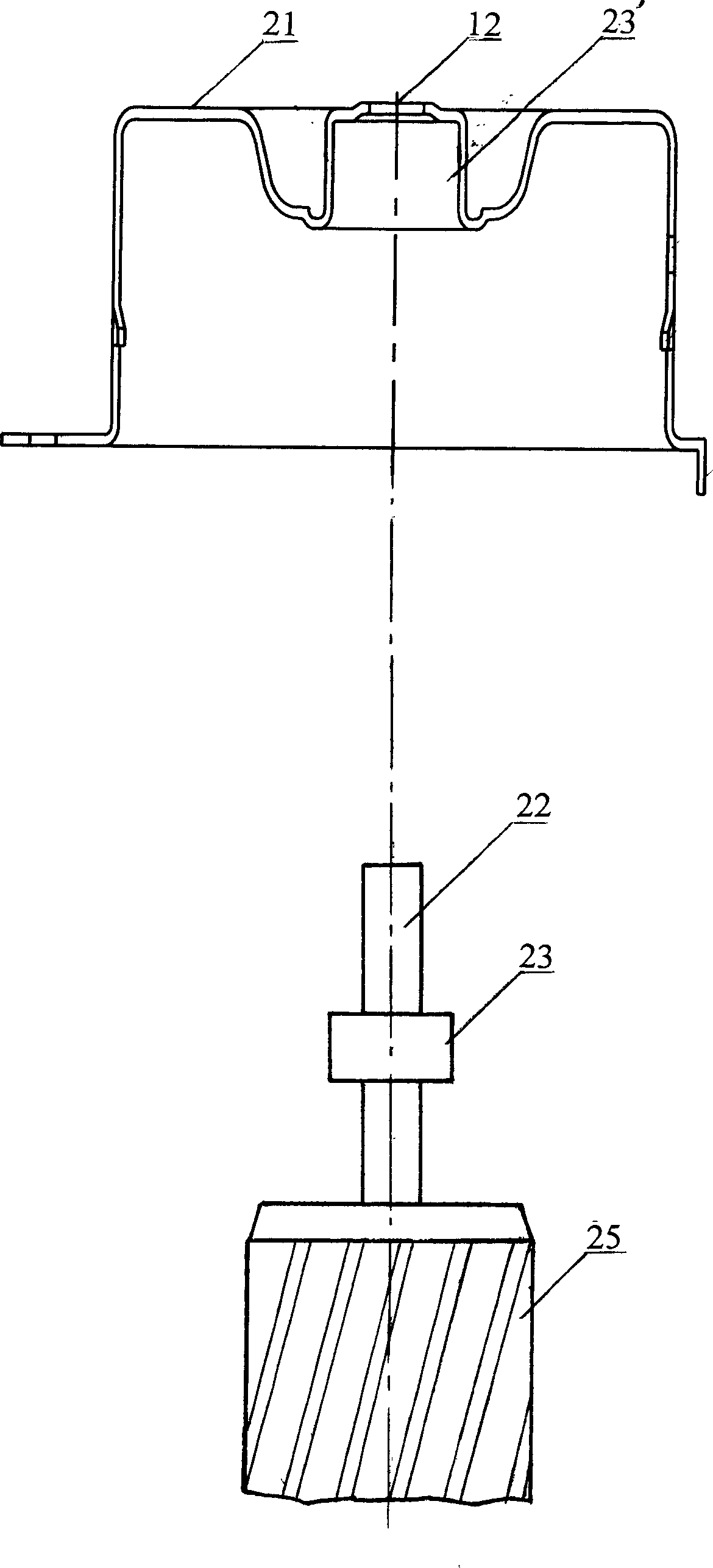

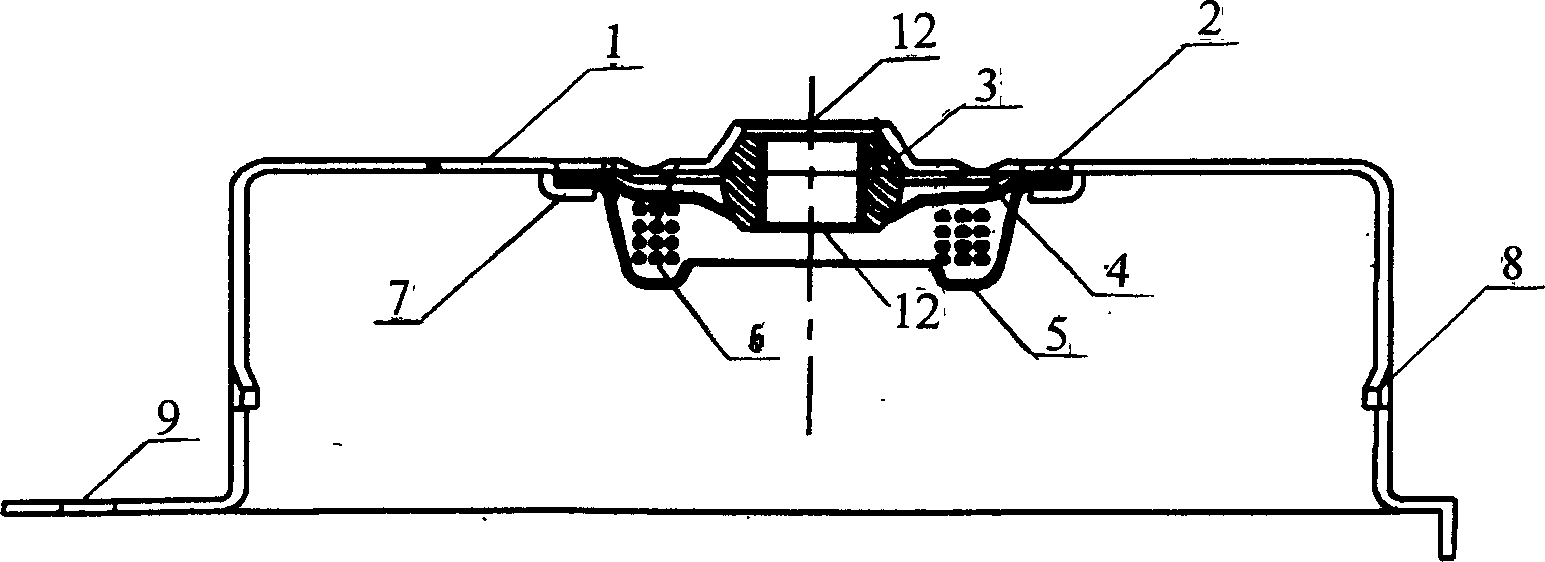

[0041] Refer to the attached Figure 3-10 Illustrated with examples, referring to each figure, the present invention includes: an oil-impregnated bearing chamber 23' and a through hole 12 for a rotating shaft are punched in the center, and an oil-impregnated bearing end cover 1 with a plurality of claws 7 punched in the center of the ring; The above-mentioned claws 7 are sequentially snapped into the inside of the end cover 1, the disc-shaped oil-impregnated bearing bracket 4 and the pot-shaped oil-impregnated bearing cover 5 with the through-hole 12 in the center; 6. The bead-shaped oil-impregnated bearing 3 installed between the oil-impregnated bearing chamber 23' and the central groove of the oil-impregnated bearing bracket 4 is formed by sliding fit.

[0042] The oil bearing chamber 23' of its oil bearing end cover 1 and the disc-shaped oil bearing bracket 4 center grooves are stamped into a shape matching the two ends of the bead shape oil bearing 3 so that the oil bearin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com