Method for making shoe soles

A manufacturing method and mold technology, applied in the field of shoe sole manufacturing, can solve the problems of shoe sole 80 production cost increase, harmful to human health, cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Please refer to the drawings, a preferred embodiment of the "sole manufacturing method" of the present invention mainly includes the following steps:

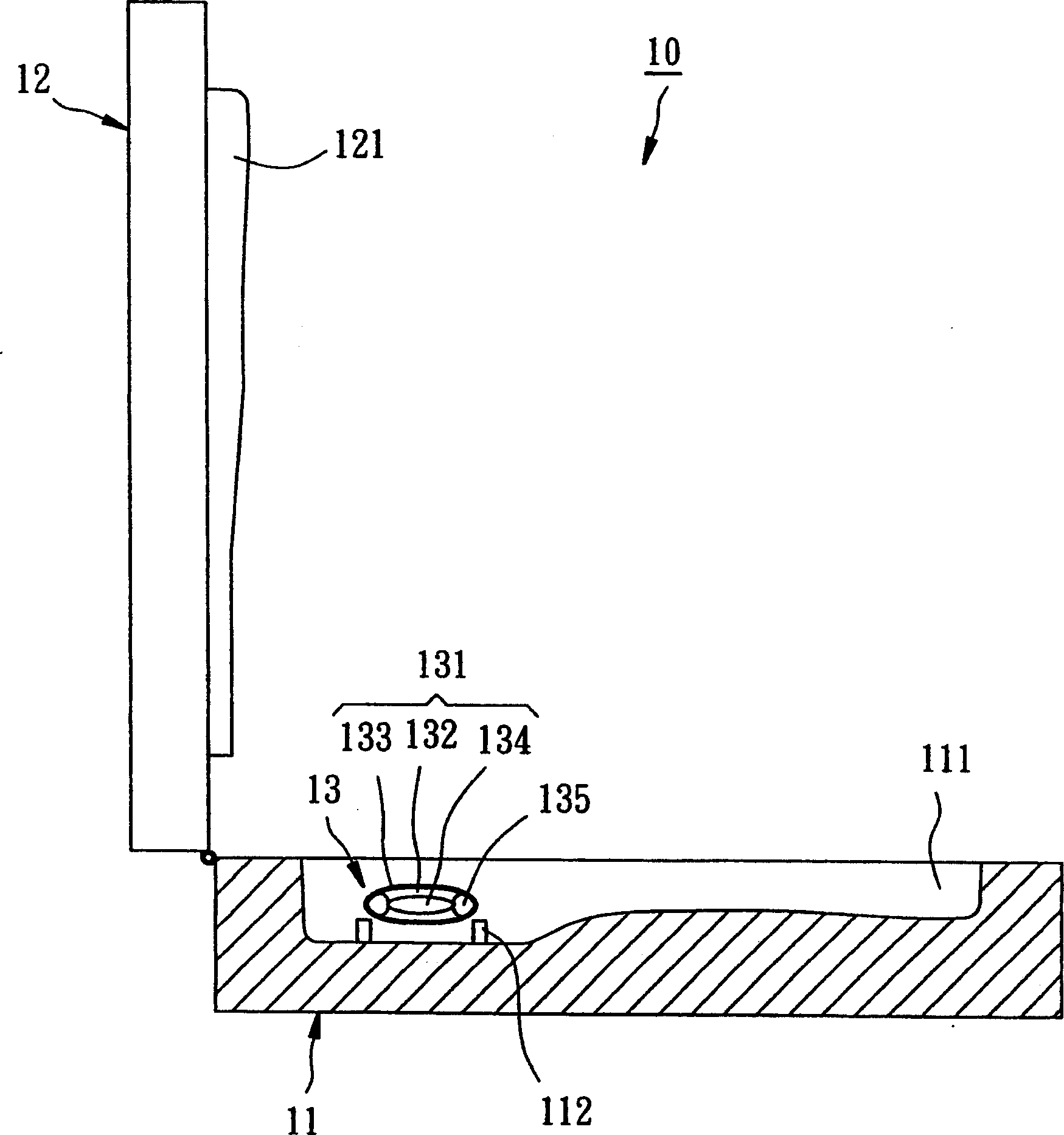

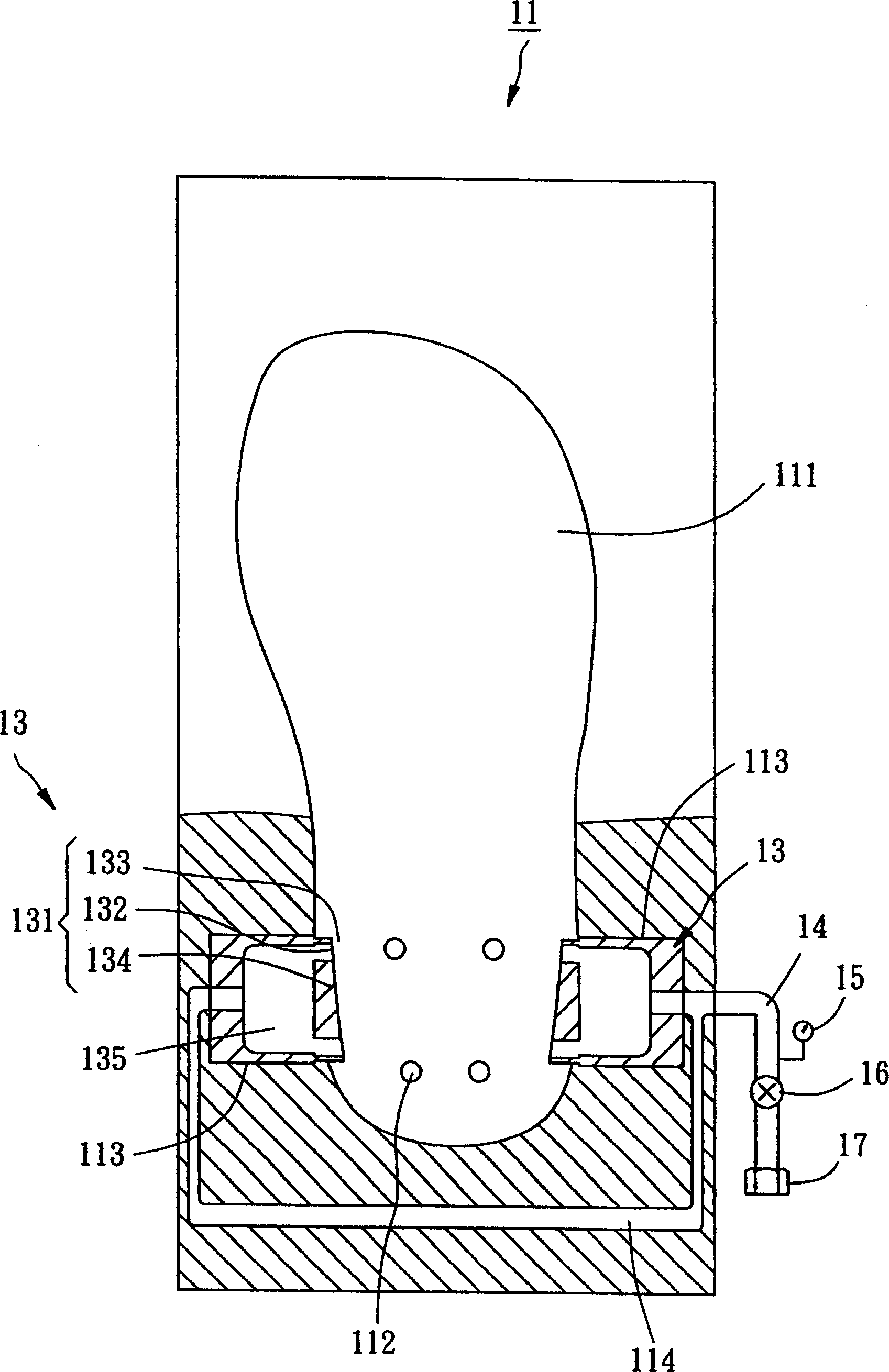

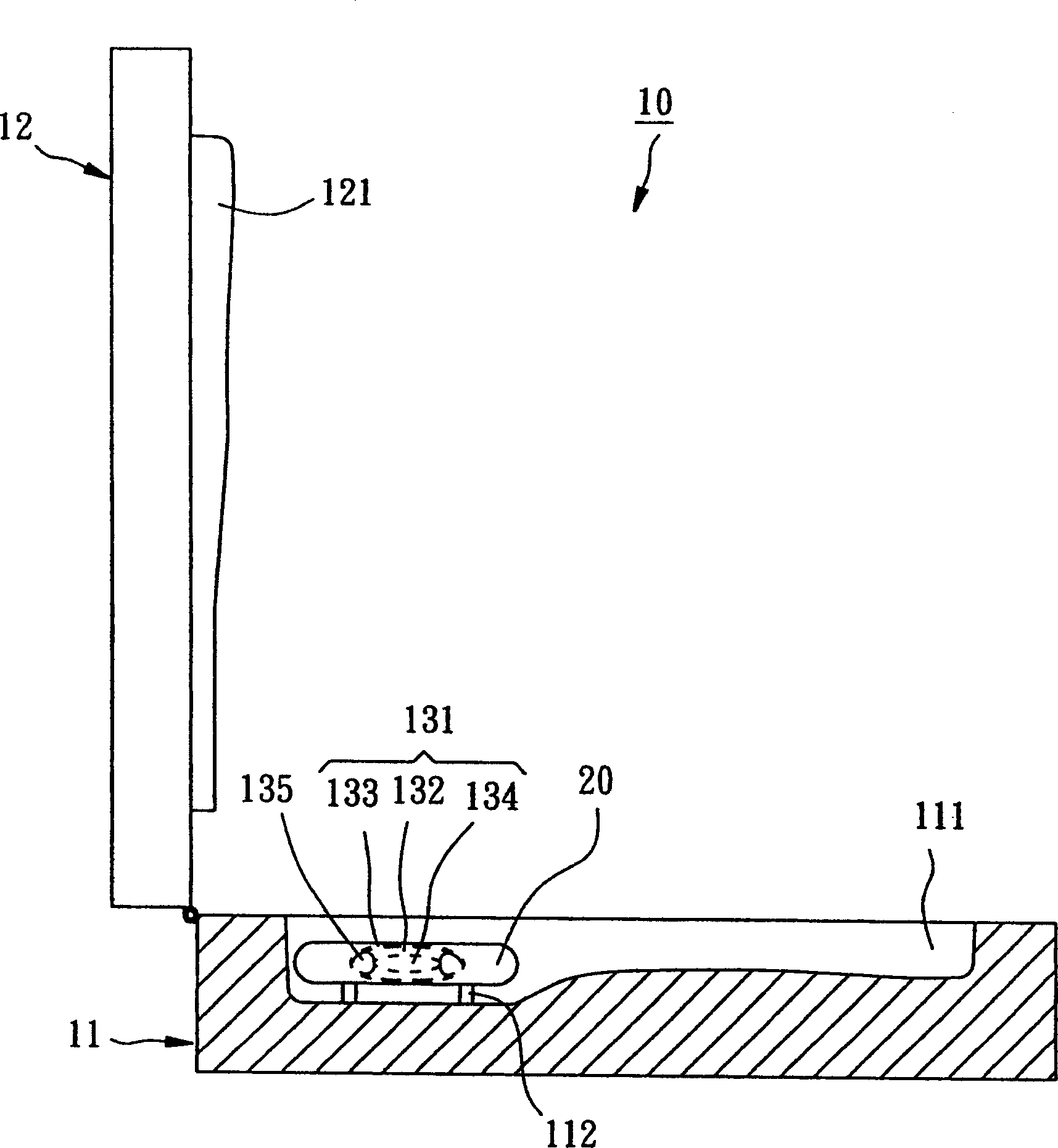

[0022] A. Take a mold 10 , an insert 20 and a suction device 30 . Among them, such as Figure 1 to Figure 3 As shown, the mold 10 includes a first mold base 11 , a second mold base 12 , two plugs 13 , a pipeline 14 , a negative pressure gauge 15 and a control valve 16 . The first mold base 11 has a mold cavity 111 in the shape of the outsole of an air-cushion shoe. There are four supports 112 at the corresponding rear heel of the mold cavity 111. The inner wall of the mold cavity 111 is provided with two accommodating grooves on both sides of the corresponding supports 112. 113 , the first mold base 11 is also provided with a flow channel 114 , and the flow channel 114 communicates with the two receiving grooves 113 and the outside of the first mold base 11 . The second mold base 12 is pivotally connected to one end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com