Freeze dryer set and process for defrosting, cleaning, and sterilizing by using same solution

A drying unit and solution technology, applied in the direction of drying solid materials, drying solid materials without heating, drying, etc., can solve the problems of poor safety performance of high temperature sterilization, accelerated aging of valves, flange connection gaskets, and equipment sealing performance Difficult to guarantee and other problems, to achieve the effect of improving production efficiency and equipment service life, increasing effective production time, and reducing production preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

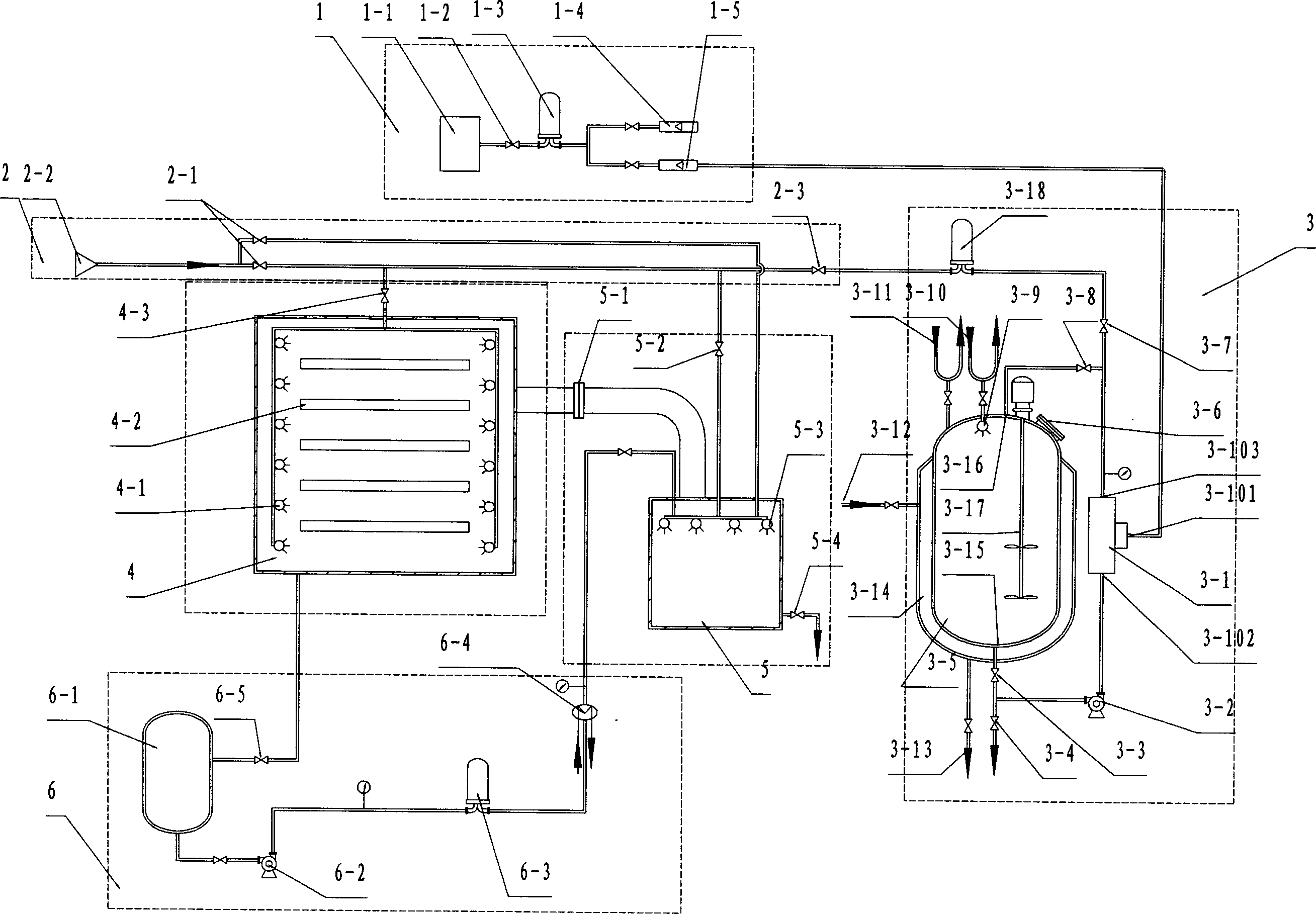

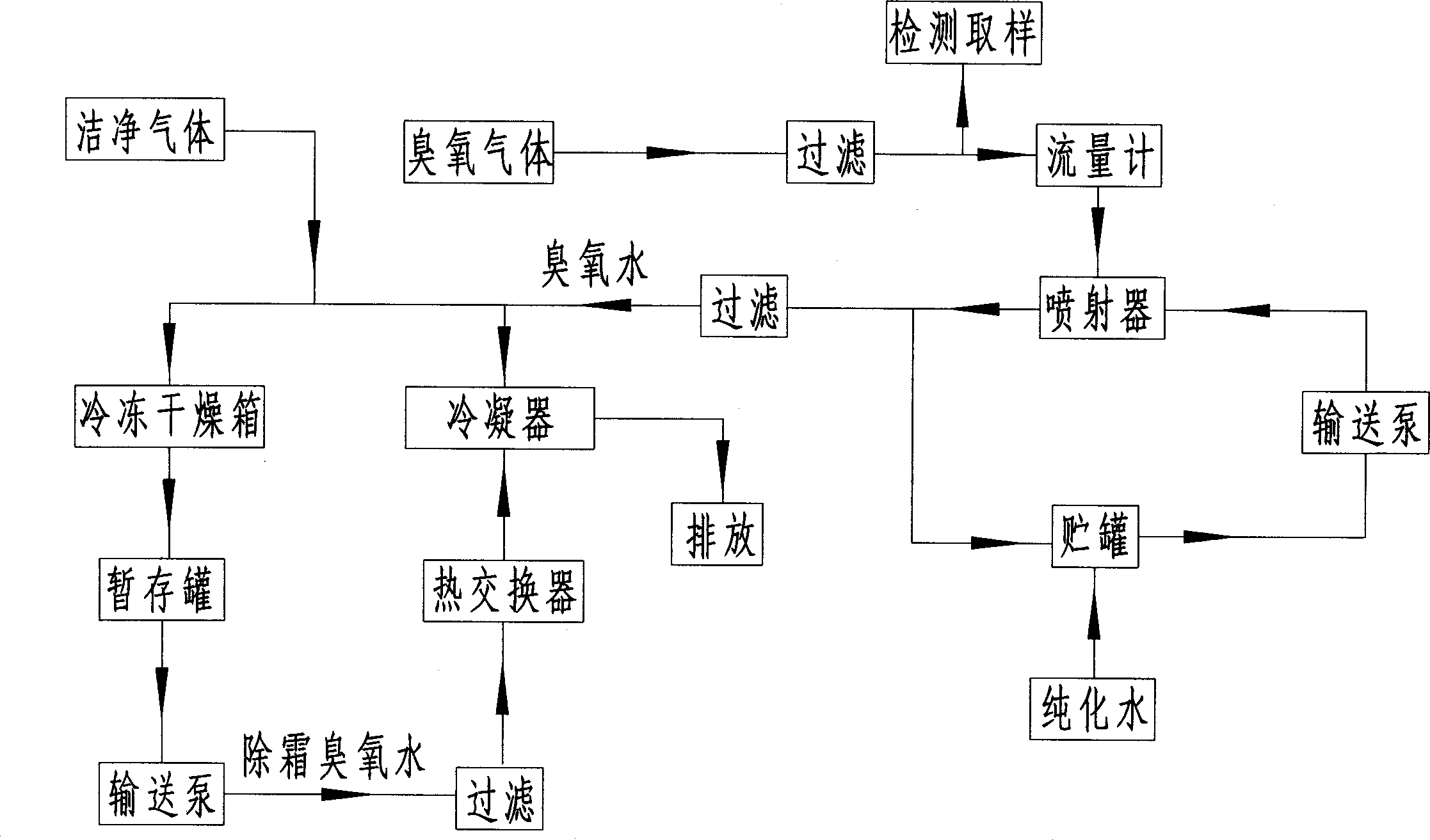

[0082] Implementation example 1: 5m 2 Examples of defrosting, cleaning and sterilization of freeze-drying units:

[0083] 1. Ozone gas generator selection:

[0084] 5m 2 Freeze-drying box for freeze-drying unit 4 volume V 1 = 1.5 cubic; condenser 5 volume V 2 =1.6 cubic, the pipeline volume that freeze-drying box 4 connects condenser 5 is V 3 =0.3 cubic, then the volume of the sterilization space is V=V 1 +V 2 +V 3 , that is, V=1.5+1.6+0.3=3.4 (cubic).

[0085] The amount of ozone generated by the ozone gas generator:

[0086] W 1 = 19.63 V 1 - 0.6225 = 19.63 × 3.4 1 - 0.6225 = 176.8 (mg / hour)

[0087] The above calculation is based on the theoretical amoun...

Embodiment 2

[0109] Implementation example two: 40m 2 Implementation example of three-in-one operation of defrosting, cleaning and sterilization of freeze-drying unit:

[0110] 1. Ozone gas generator selection:

[0111] 40m 2 Freeze drying unit Freeze drying box 4 volume V 1 18 cubic meters; condenser 5 volume V 2 It is 18 cubic meters, and the volume of the freeze-drying box 4 connected to the condenser 5 is V 3 is 0.5 cubic,

[0112] Then the volume of the sterilization space is V=V 1 +V 2 +V 3

[0113] =18+18+0.5

[0114] =36.5 (cubic).

[0115] The amount of ozone generated by the ozone gas generator 1-1:

[0116] W 1 = 19.63 V 1 - 0.6225 = 19.63 × 36.5 0.377

[0117] = 19.005172 (mg / hour) ...

Embodiment 3

[0129] Implementation example three: 60m 2 Implementation example of three-in-one operation of defrosting, cleaning and sterilization of freeze-drying unit:

[0130] 1. Ozone gas generator selection:

[0131] 60m 2 Freeze drying unit Freeze drying chamber volume V 1 is 24.5 cubic; condenser volume V 2 It is 20 cubic meters, and the volume of the freeze-drying box 4 connected to the condenser 5 is V 3 is 1 cubic meter,

[0132] Then the volume of the sterilization space is V=V 1 +V 2 +V 3

[0133] =24.5+20+1

[0134] =45.5 (cubic).

[0135] Ozone Gas Generator 1-1 Ozone Generation:

[0136] W 1 = 19 . 63 V 1 - 0.6225 = 19.63 × 45.5 0.377

[0137] =2369.1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com