Combined detection method for high-purity SO3 gas and impurity SO2 gas therein

A SO2, high-purity technology, applied in chemical analysis by titration, material analysis by observing the influence of chemical indicators, and analysis by making materials react chemically, etc. Detection and other problems, to achieve the effect of good measurement precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

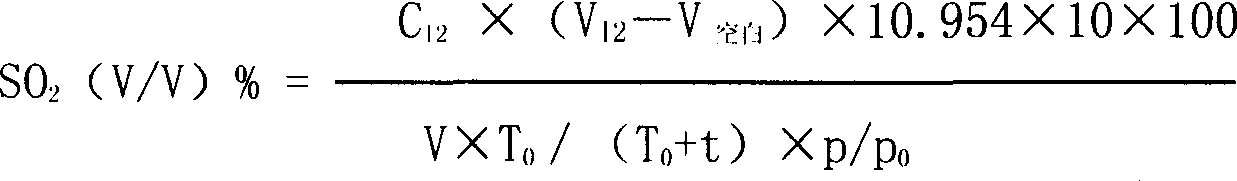

Method used

Image

Examples

Embodiment 1

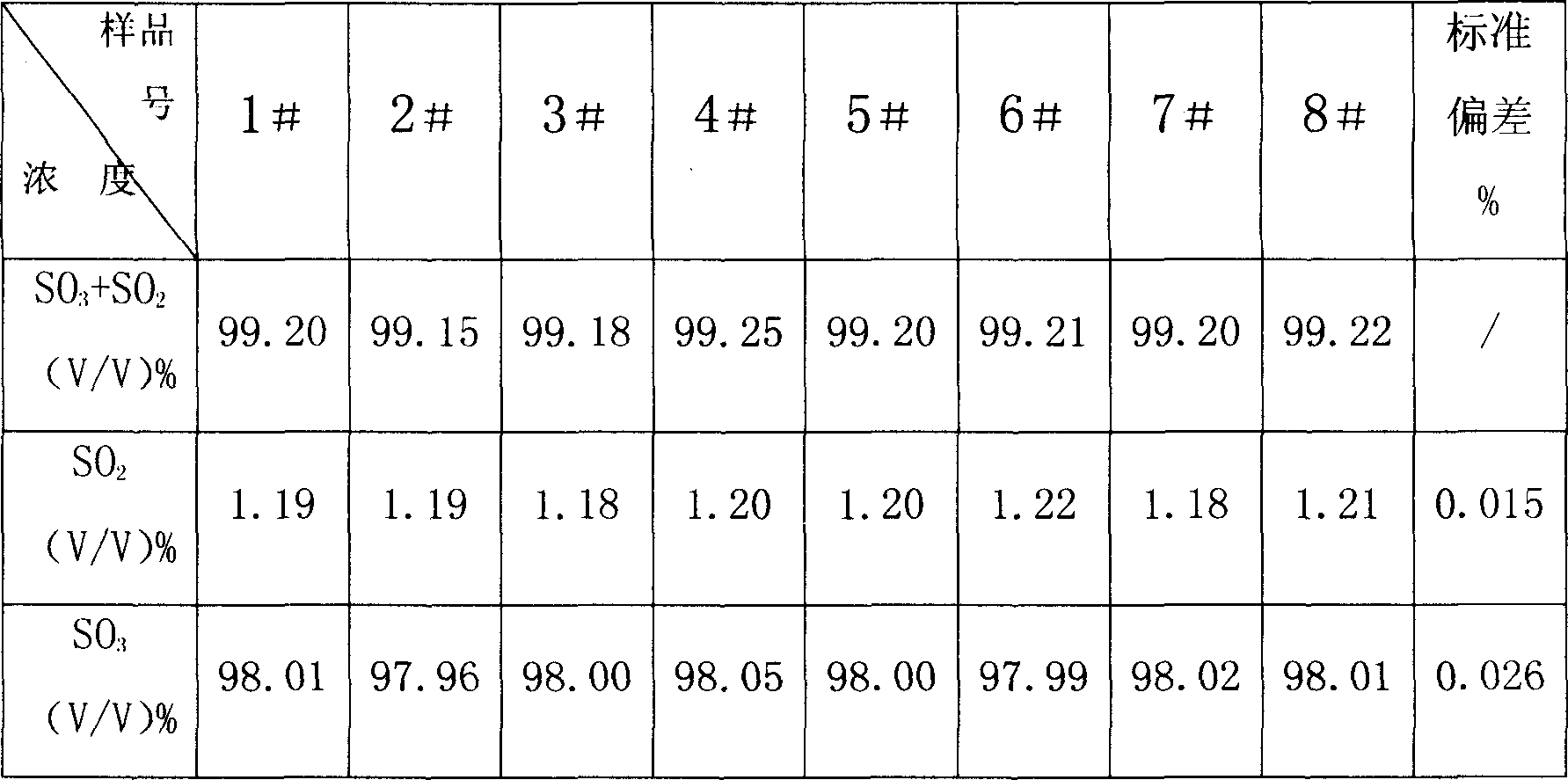

[0041] The test was carried out under the climate conditions of 35°C and 1 atmosphere, the temperature inside the insulation jacket was controlled to be 70°C, and the gas temperature was 70°C. The test results are as follows:

[0042]

Embodiment 2

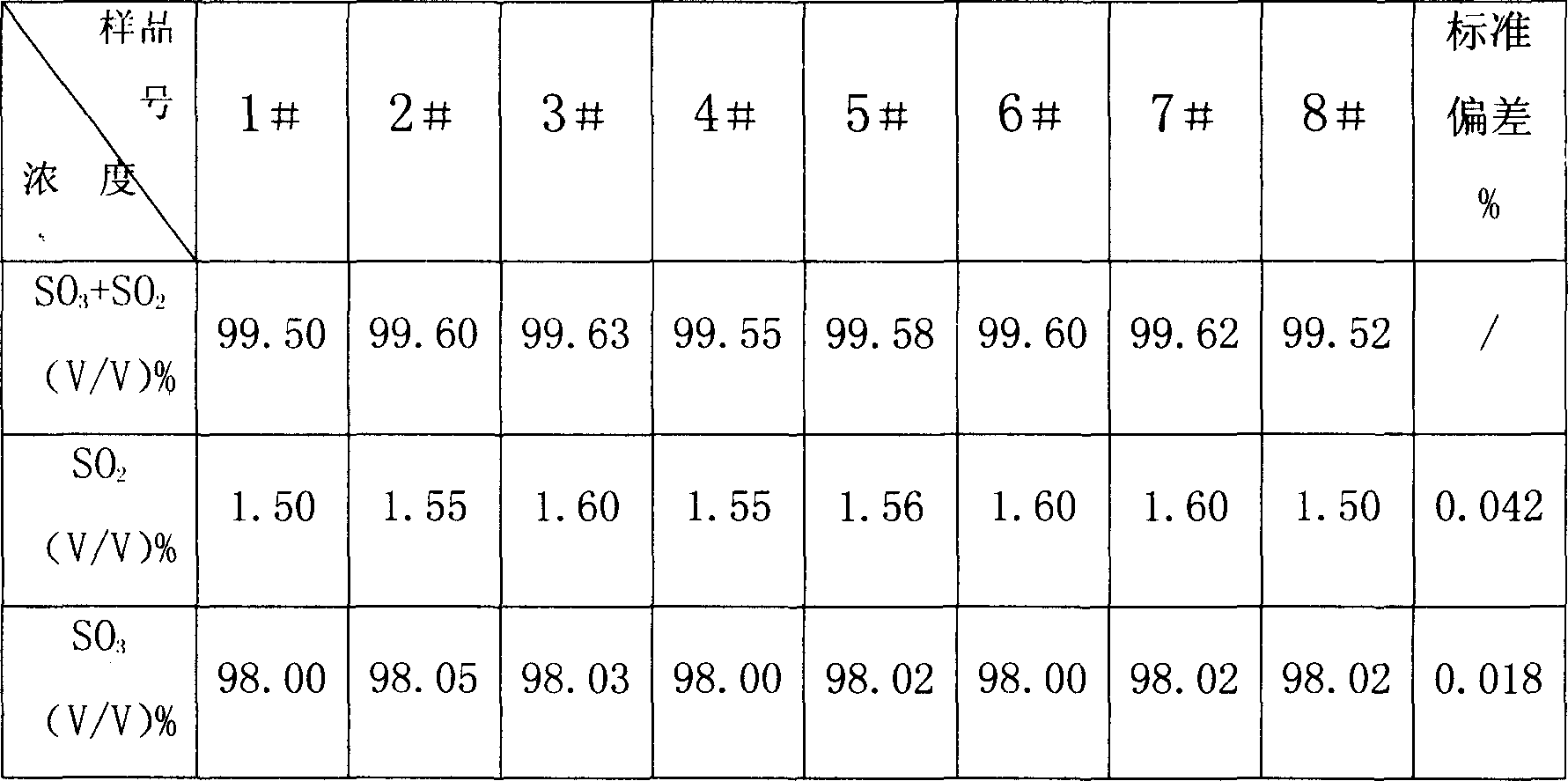

[0044] The test was carried out under the climate conditions of 5°C and 1 atmosphere, the temperature inside the insulation jacket was controlled to be 70°C, and the gas temperature was 70°C. The test results are as follows:

[0045]

[0046] According to the data obtained above and the standard deviation value, it is shown that under the condition of stable gas flow, high-purity SO in this method 3 Gas and its impurity SO 2 The measurement precision of gas volume percentage concentration is good, and the measurement standard deviation is not more than 0.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com