MEMS microprobe and preparation method thereof

A micro-probe and mechanics technology, applied in the field of MEMS mechanical micro-probe and its preparation, can solve problems such as high price, and achieve the effects of being beneficial to online detection, convenient control and accurate detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

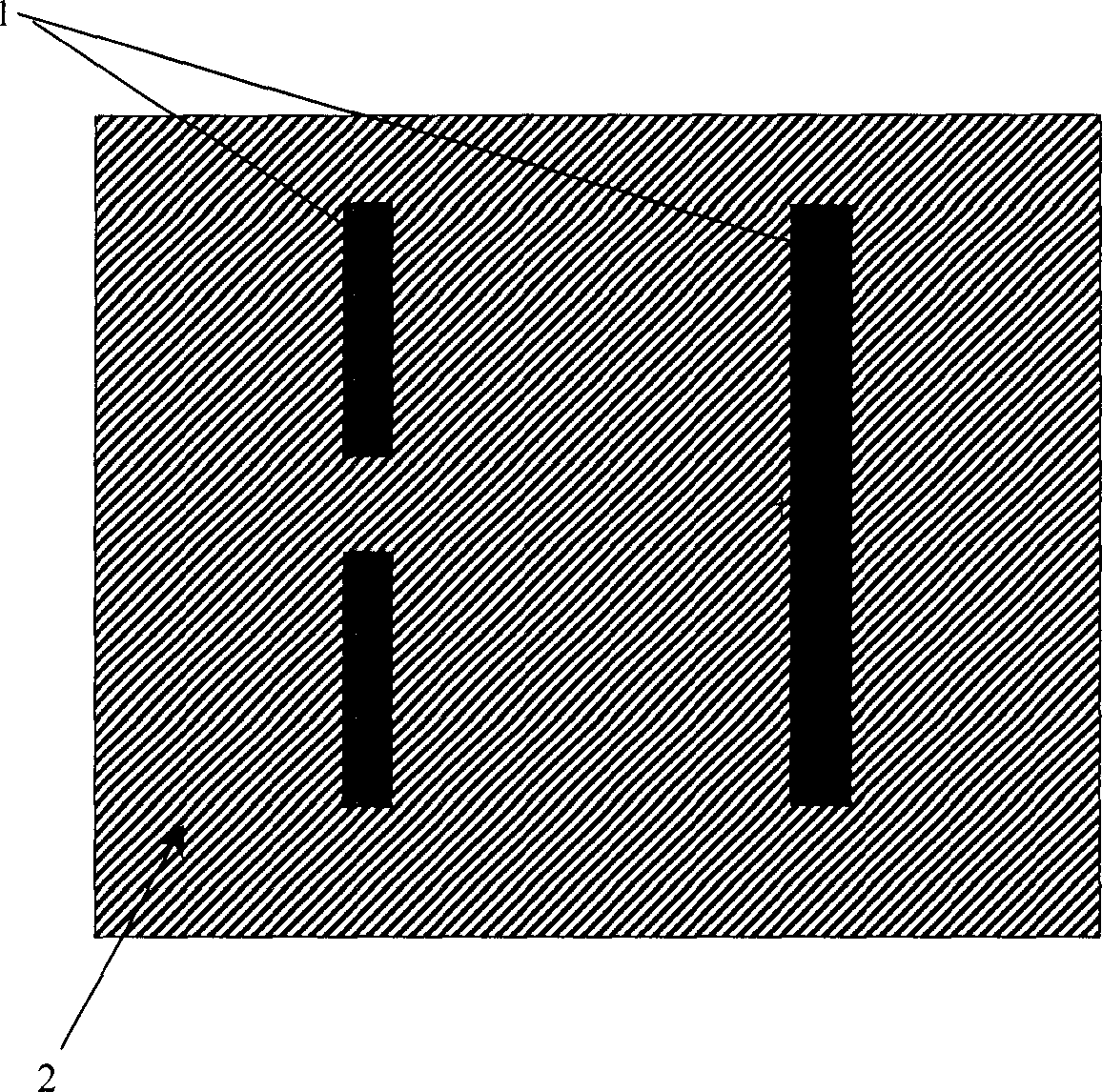

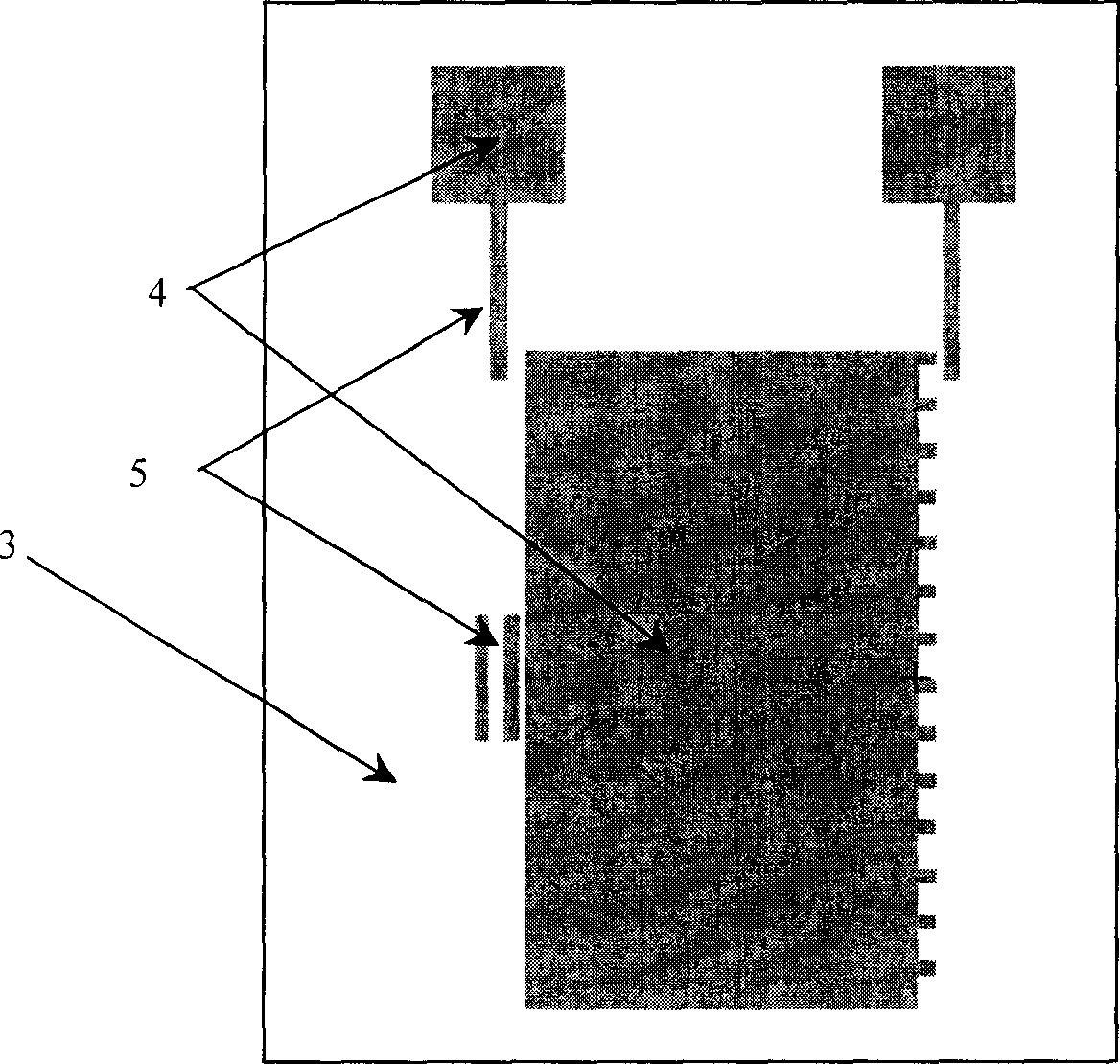

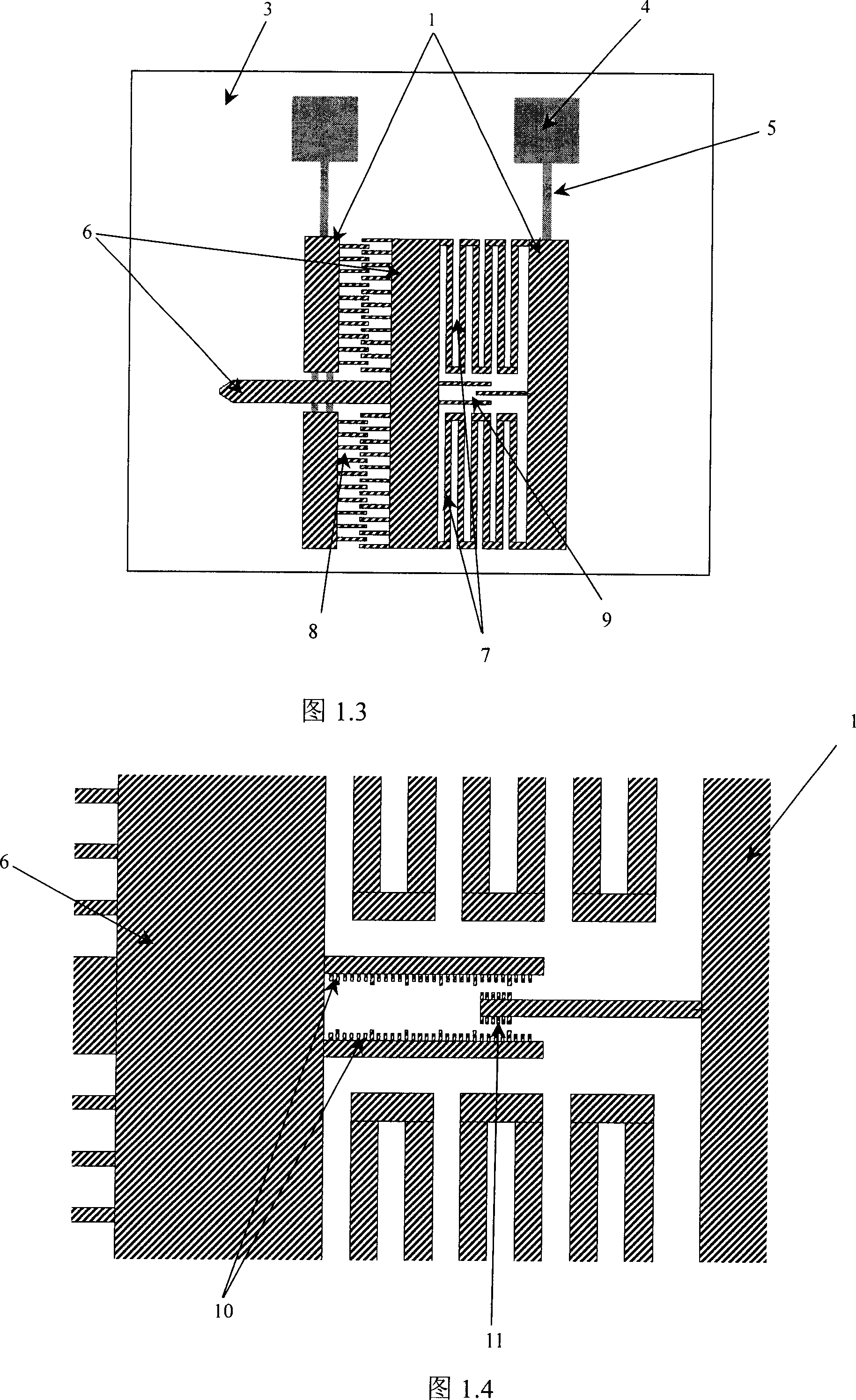

[0040] Microprobe structure:

[0041] Refer to Figure 1.3, Figure 1.4, Figure 1.5 as well as Figure 2.4 , the microprobe structure of the present invention is generally divided into an upper monocrystalline silicon structure probe body and a lower glass structure substrate 3, and the upper monocrystalline silicon structure probe body part includes: a fixed anchor point (anchor) 1, a T-type probe Head 6, elastic beam structure 7, comb capacitor 8 and readout scale 9. The T-shaped probe head 6 is suspended on the substrate through the elastic beam 7 connected to the fixed anchor point 1. Two comb-toothed capacitors 8 are respectively arranged on the shoulder of the T-shaped probe head 6, and one side of the comb-toothed capacitor 8 The pole plate is connected to the fixed anchor point 1, and the other side plate of the comb capacitor 8 is connected to the T-shaped probe head 6. The scale structure includes: two parts: the moving ruler 10 and the fixed ruler 11, the moving ru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com