Method and apparatus for repairing high-capacity waste lead accumulator by variable combined pulse

A combination of pulse and lead-acid battery technology, applied in battery circuit devices, pulse technology, pulse processing, etc., can solve the problem of low power utilization and achieve the effect of saving power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

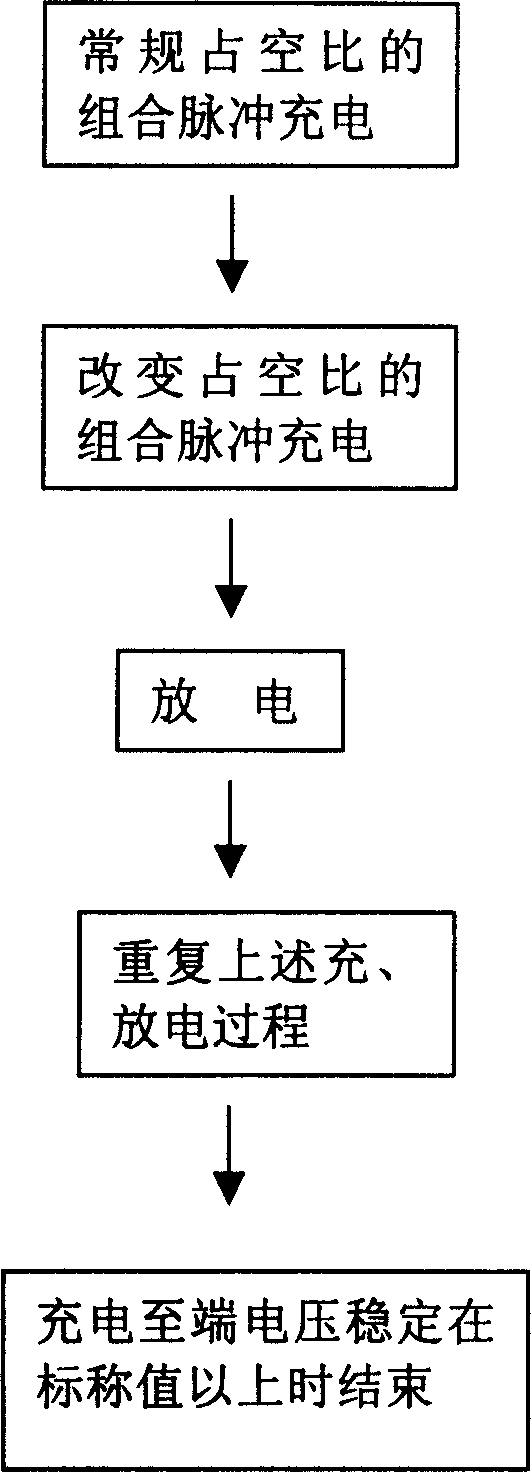

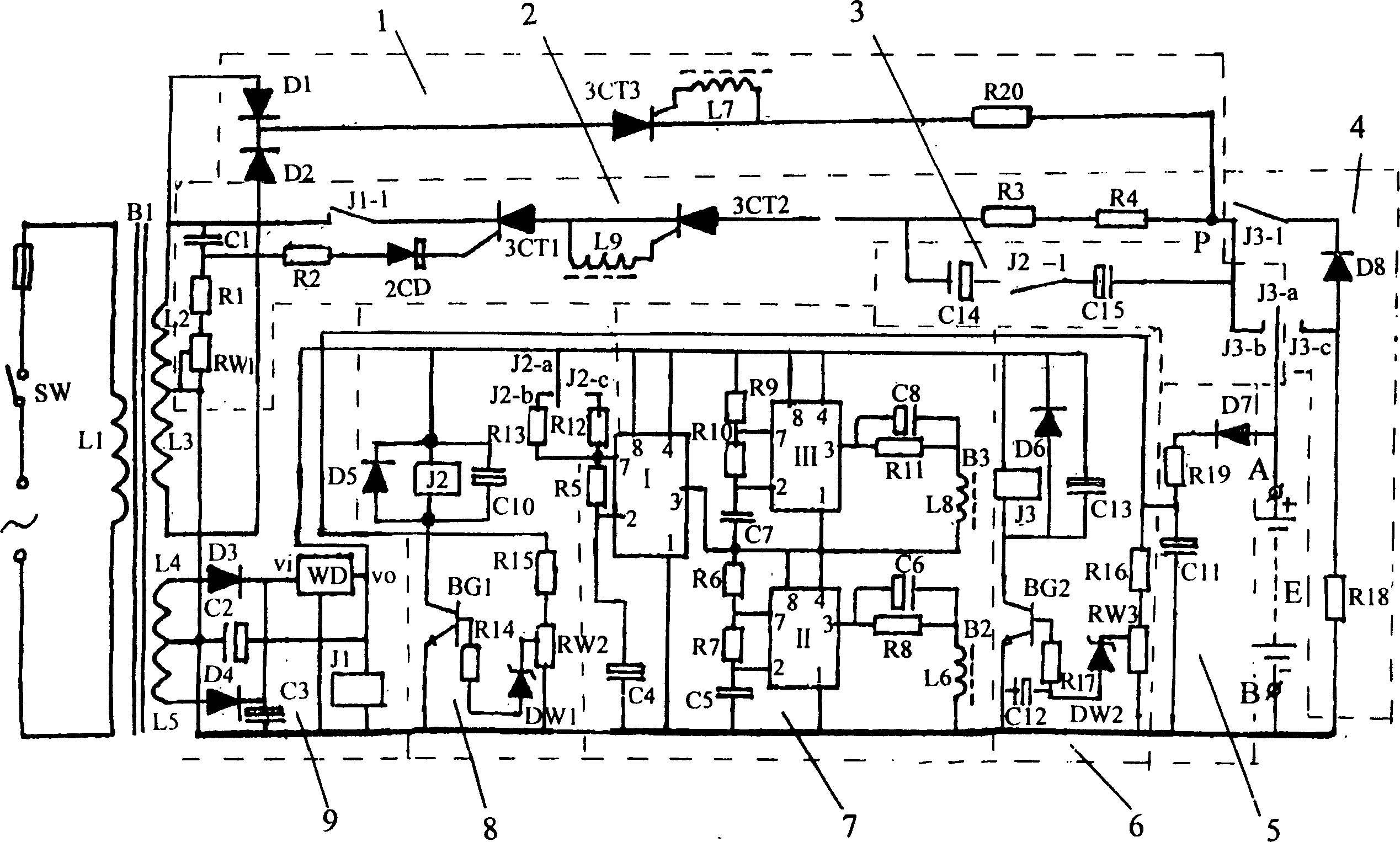

[0021] Combine now figure 1 As shown, the detailed process of the large-capacity waste lead storage battery change combination pulse charging repair method of the present invention is described as follows:

[0022] 1. Use the combined pulse of the conventional duty cycle to charge until the charge is 65% to 75%.

[0023] At this stage, the combined pulse is charged and repaired with the large-capacity waste lead storage battery to be repaired with a large current according to the duty cycle of the conventional combined pulse positive and negative pulse charging time. This process is combined with the existing use The pulse charging method is the same. In the initial stage of charging and repairing, the terminal voltage of the battery increases with the increase of the storage capacity. Due to the existence of negative pulses and the low reduction rate of the battery plate material, there are few bubbles in the electrolyte.

[0024] 2. Increase the negative pulse charging tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com