Boat propeller and method for assembling the same

A technology for marine propellers and propellers, which is applied in the direction of rotating propellers, ship propulsion, ship parts, etc., can solve the problems of cumbersome, expensive propellers, lack of flexibility and adaptability, etc., and achieve the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

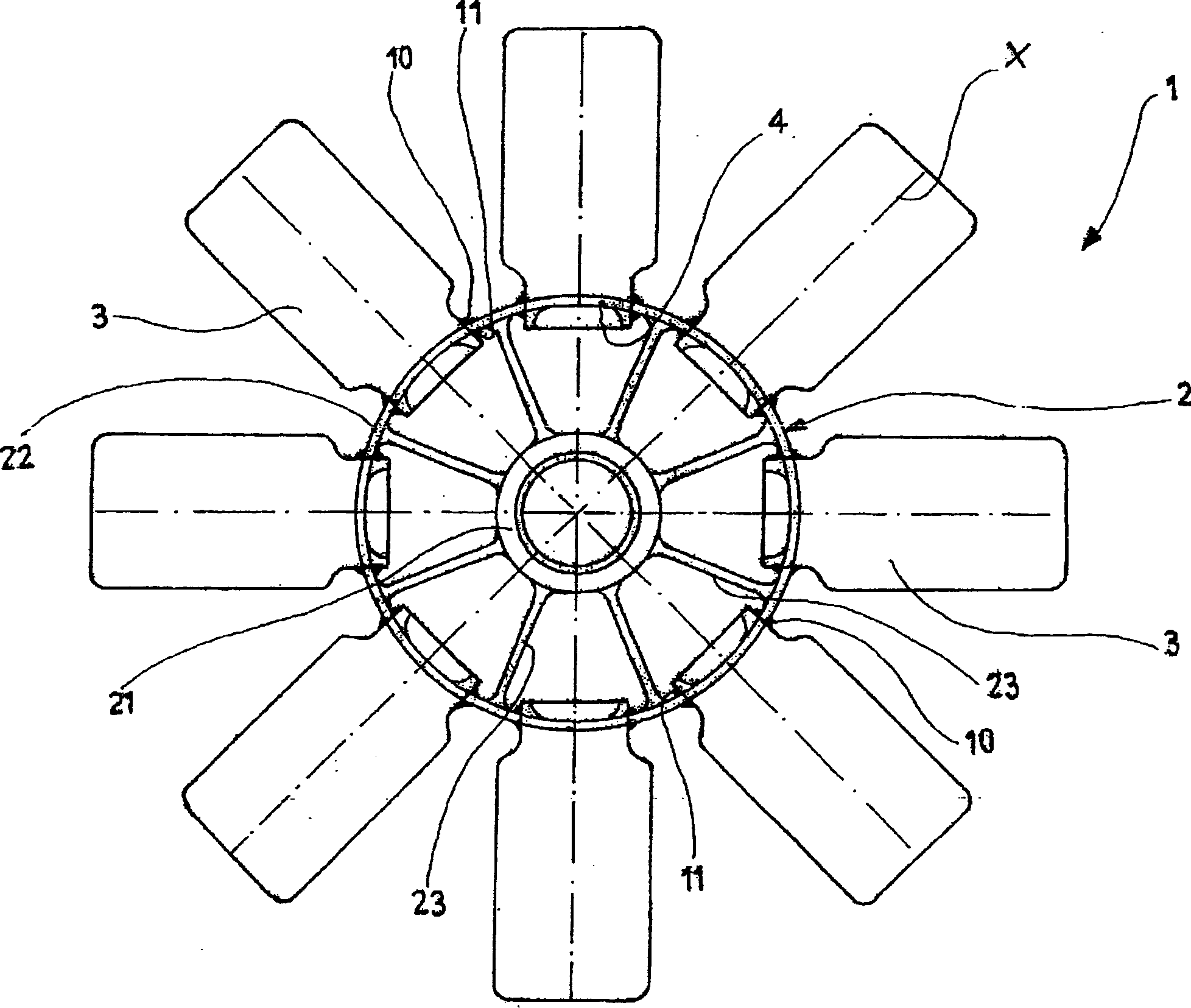

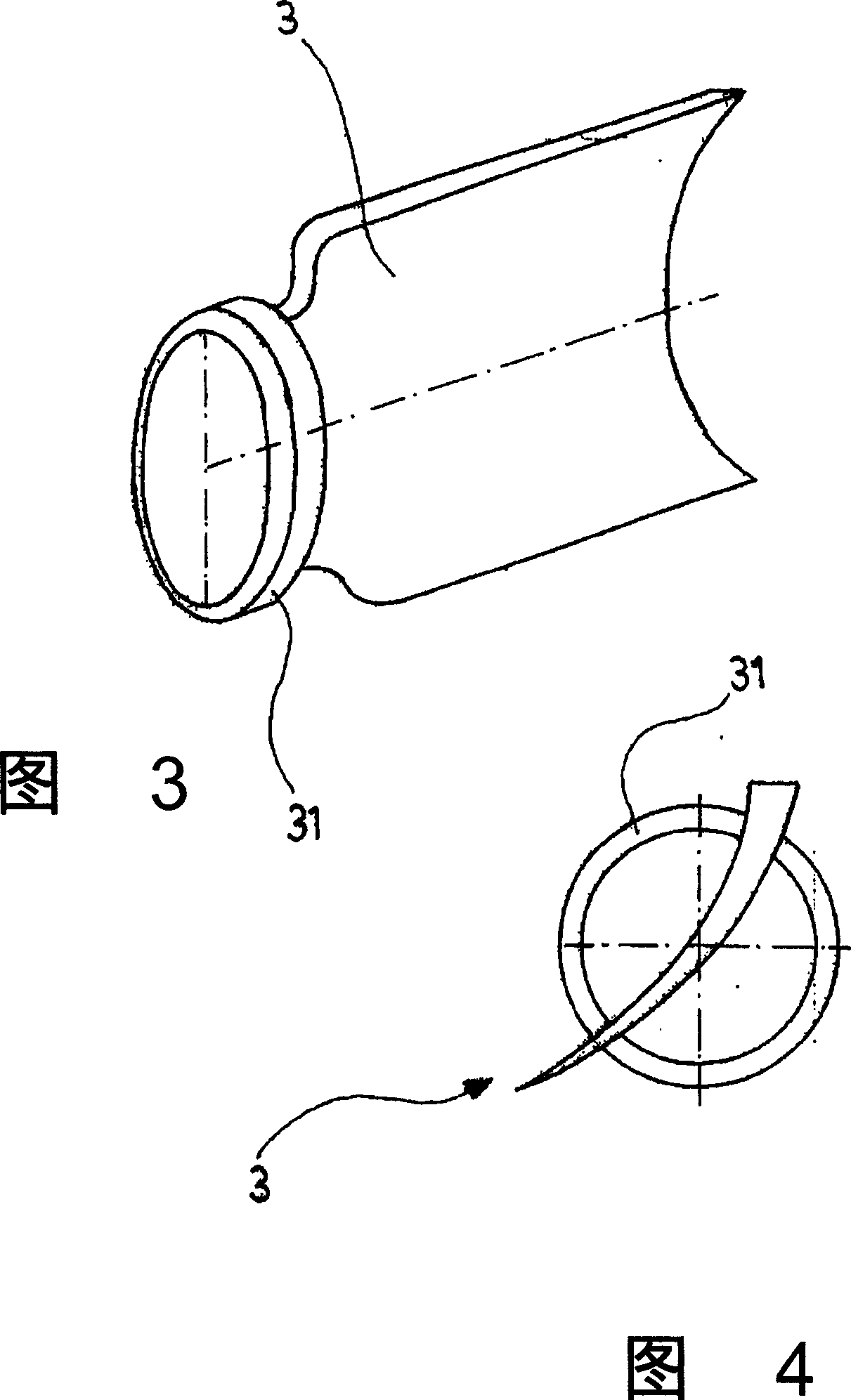

[0033] figure 1 A propeller 1 according to the invention is shown, which consists of a hub 2 and a plurality of blades 3 . The blade 3 can be two or more and manufactured independently of the hub 2, and they are connected to the hub 2 during assembly. Accordingly, the hub 2 has a housing 4 adapted to receive a part of the blade 3 . best as figure 1 As shown, the X-axis of each blade coincides with the axis of the corresponding housing hole 4 . This has the advantage that the blades 3 can be oriented during assembly of the propeller 1 , ie they can be rotated about the X-axis before they are fixedly mounted.

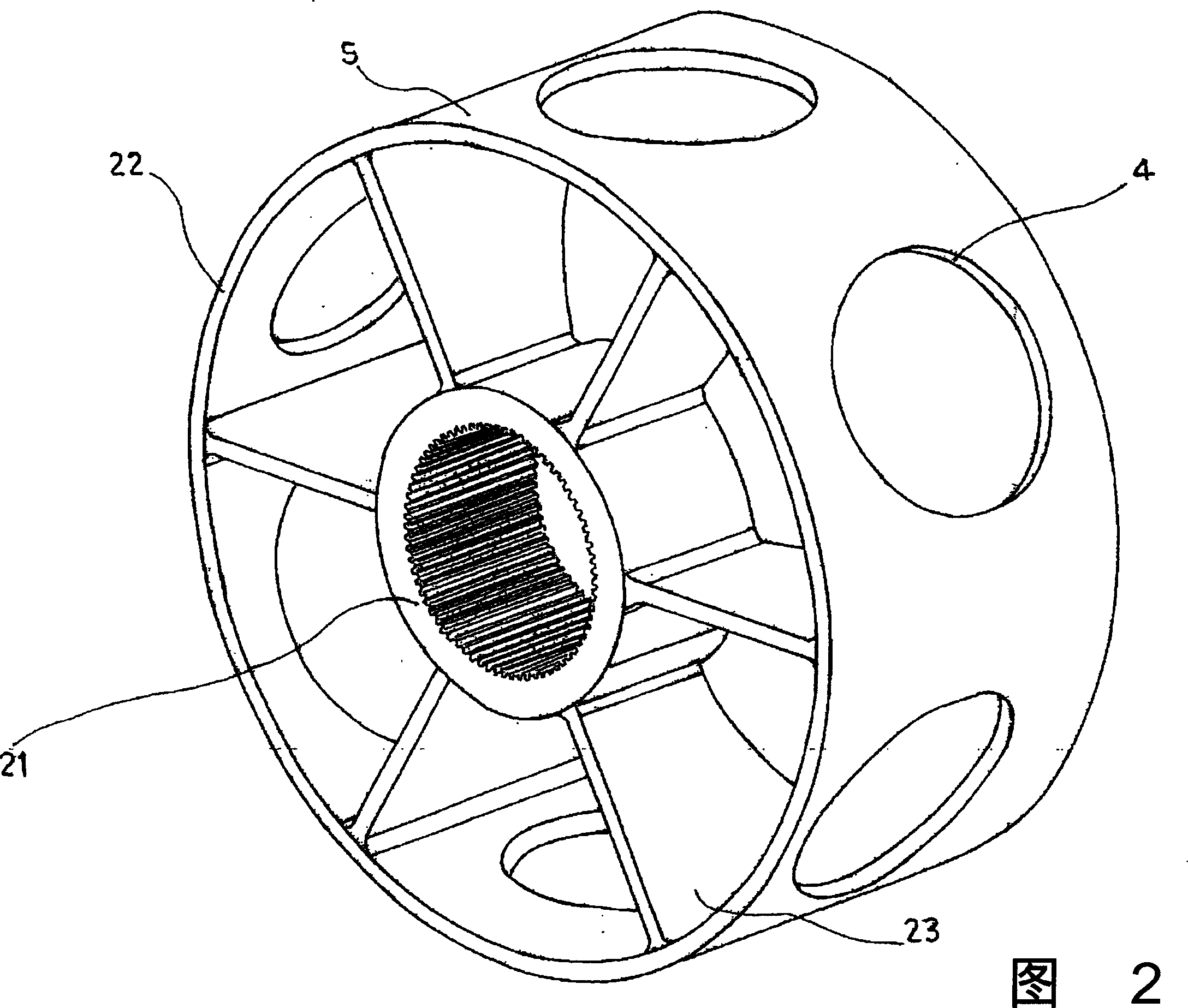

[0034] Such as figure 1 The shown propeller hub 2 comprises a central part 21 and an outer ring 22 . The outer ring 22 is connected to the central part 21 of the hub by a plurality of spokes 23 . The paddle hub 2 is particularly light in weight compared with conventional paddle hubs of the same diameter. The blades 3 are fixed on the outer ring 22 of the hub 2 . T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com