Method for preparing mixed solvent of alkyl phthalic imidine

A technology of alkyl phthalimide and mixed solvent, which is applied in the field of preparation of N-alkyl phthalimide mixed solvent, can solve the problems of energy consumption, time consumption, complicated process and the like, and achieve cost Low, high product purity, the effect of reaction moderation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

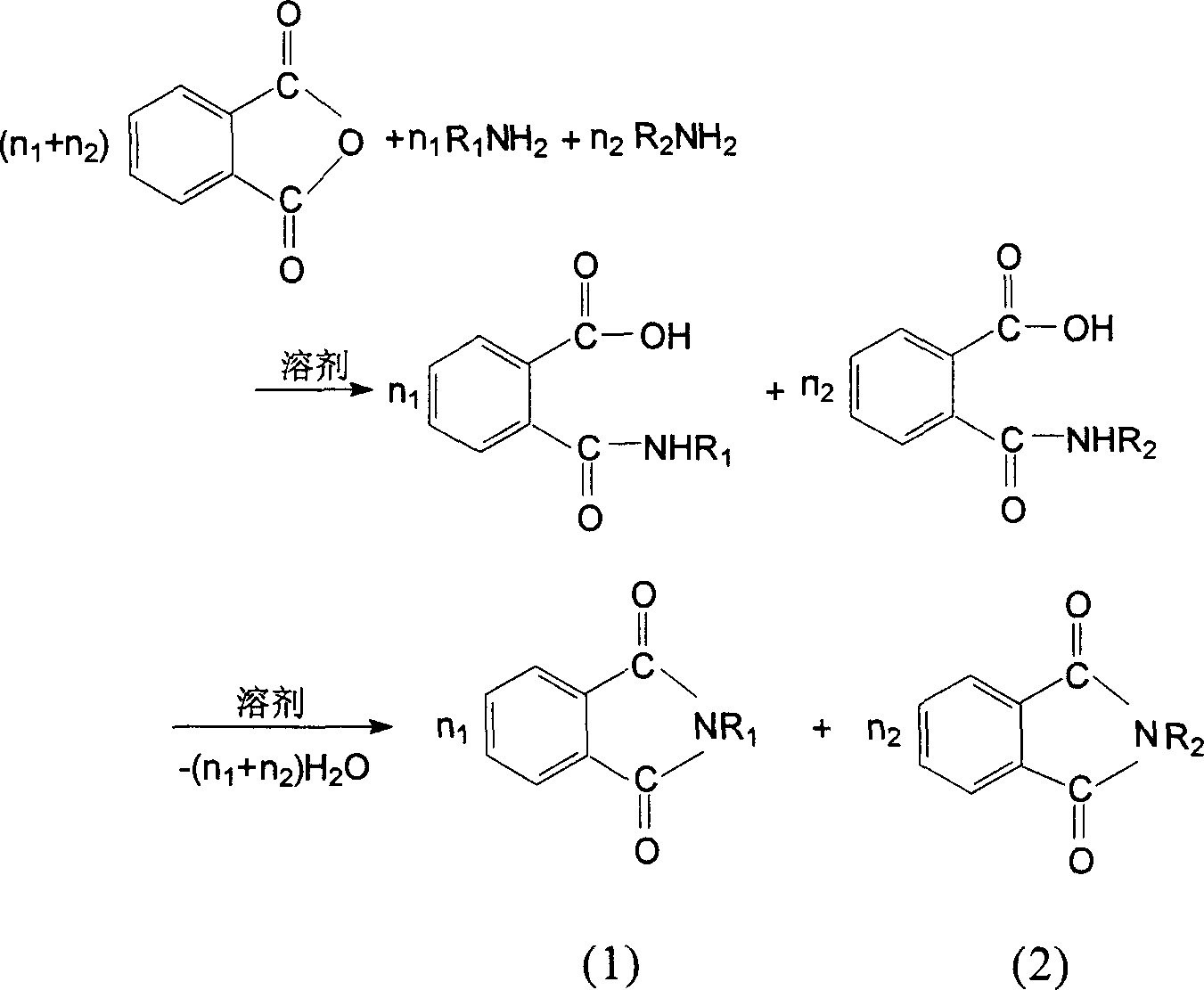

Method used

Image

Examples

preparation example Construction

[0053] The yield of the preparation method of the present invention is more than 97%, the purity of the prepared N-alkylphthalimide mixed solvent is more than 99% by weight, and it is a clear oily liquid, which is convenient for transportation and treatment, and can be directly used in industrial applications .

[0054] In order to further purify the N-alkylphthalimide prepared by the method of the present invention, it can be decolorized with activated carbon or vacuum distilled.

Embodiment 1

[0058] In a 500 ml round-bottomed three-necked flask equipped with a mechanical stirrer, a thermometer and a reflux dehydration condenser, add 140 ml of industrial mixed xylene, 59.2 g (0.400 mol) of phthalic anhydride, 8.12 g (0.138 mol) of isopropylamine ) and n-butylamine 21.59 g (0.295 mol). The temperature of the reactant was slowly raised to 80-90° C. under stirring, and the temperature was maintained for 1 hour, and then the temperature was raised to the reflux temperature of the reactant. Maintain this temperature for 6-7 hours. The water generated by the reaction is removed from the reaction system in time by means of azeotropic reflux.

[0059] After the reaction is over, xylene is recovered by normal pressure distillation at 140-150°C. Then adopt 100 Torr vacuum distillation to remove trace xylene remaining in the material.

[0060] 79.2 g of the N-alkylphthalimide mixture were obtained. The product is analyzed by high-performance liquid chromatography (detectio...

Embodiment 2

[0063] In a 500 ml round-bottomed three-necked flask equipped with a mechanical stirrer, a thermometer, an addition funnel, and a reflux dehydration condenser, add 80 ml of industrial mixed xylene and 59.2 g (0.400 mol) of phthalic anhydride, and slowly Slowly raise the temperature of the reactant to 80-90° C., and add the xylene solution of the organic amine dropwise at this temperature. The solution consists of 28.06 grams of n-butylamine and 6.25 grams of isopropylamine dissolved in 60 milliliters of industrial mixed xylene. The dropwise addition time is about 1 hour. After the dropwise addition, the temperature was raised to the reflux temperature of the reactant. The reaction temperature was maintained for 6-7 hours. The water generated by the reaction is removed from the reaction system in time by means of azeotropic reflux.

[0064] After the reaction is over, xylene is recovered by normal pressure distillation at 140-150°C. Then adopt 100 Torr vacuum distillation to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com