Technique for extracting and washing sulfurized isobutene

A sulfurized isobutylene and process technology, which is applied in the field of sulfurized isobutylene washing process, can solve the problems of lower equipment utilization, long temperature time, large amount of solvent gasoline, etc., and achieve the effect of energy saving and less extractant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

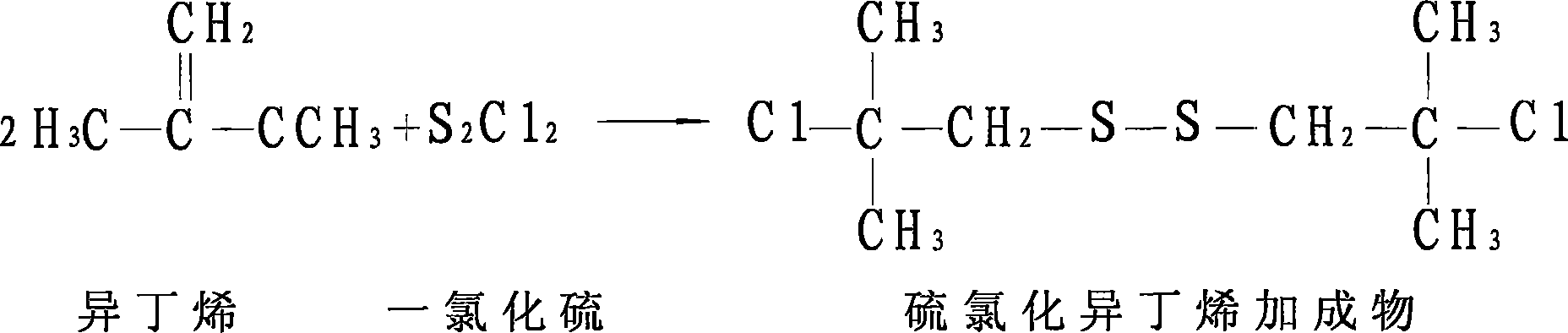

[0020] 1) Add 500Kg of sulfur monochloride, 390Kg of isobutylene, and 11Kg of methanol into the reaction kettle at room temperature and react at 50°C for 4 hours to obtain 835Kg of adduct, which is added to the dechlorination tower, and 100Kg of isopropanol and 18% of sodium sulfide are added dropwise The solution was 500Kg, refluxed at 82°C for 3 hours, after the reaction was completed, the temperature was raised to 90°C, and the isopropanol was recovered under reduced pressure to obtain crude isobutylene sulfide.

[0021] 2) At room temperature, methanol and water are used to configure detergent according to the volume ratio of 1:10; take 1000Kg of crude product, add 300Kg of detergent, stir for 15min, then raise the temperature to 65°C, distill for 10min under vacuum at 0.05Mpa, and distill out Methanol; stand still for 30 minutes, separate the water after separation, then raise the temperature to 120-125°C, and distill at a vacuum degree of 0.08Mpa to obtain 980Kg of sulfur...

Embodiment 2

[0023] Start from step 2), at room temperature, methanol and water are used to prepare detergent according to the volume ratio of 1:10; take 1000Kg of crude product, add 350Kg of detergent, stir for 18min, then heat up to 68°C, and distill at a vacuum of 0.05Mpa After 13 minutes, methanol was distilled off; after standing still for 35 minutes, the water was removed after the layers were separated, and then the temperature was raised to 125-130°C, and the finished product of sulfurized isobutylene was obtained by distillation under a vacuum degree of 0.08Mpa. All the other are with embodiment 1.

Embodiment 3

[0025] Starting from step 2), under normal temperature, methanol and water are used to configure detergent according to the volume ratio of 1:10; take 1000Kg of crude product, add 400Kg of detergent, stir for 20min, then heat up to 70°C, and distill at a vacuum of 0.05Mpa After 10 minutes, methanol was distilled off; after standing still for 40 minutes, the water was separated after the layers were separated, and then the temperature was raised to 135-140°C, and the finished product of sulfurized isobutylene was obtained by distillation under a vacuum degree of 0.08Mpa. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com