Mixing refrigerant in use for repalcing R12 and R500

A mixed refrigerant and R12 technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of large temperature difference and refrigeration performance impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

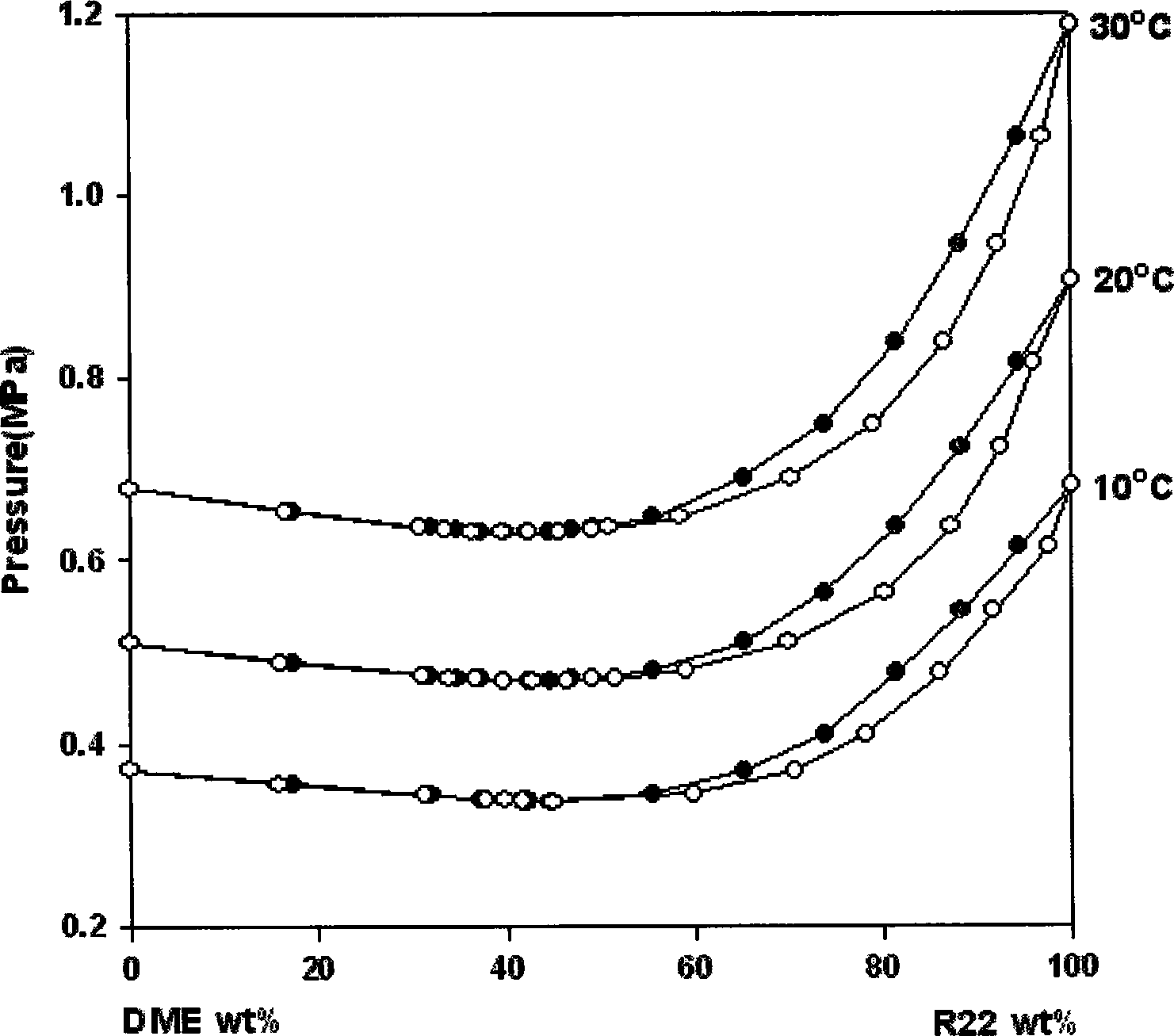

[0022] In this embodiment, the mixed refrigerant is a specific mixture composed of chlorodifluoromethane (R22) 0-100% and dimethyl ether (Dimethyl ether) 0-100%. This embodiment proves through experiments that the mixed refrigerant exhibits azeotropic or near-azeotropic properties within the appropriate composition range of the two components; that is, it exhibits the same or almost similar boiling points of liquid and vapor compositions, that is, within the above range exhibit essentially the same or similar vapor pressure composition.

[0023] The experiment was performed at a temperature of 10°C, 20°C, and 30°C (constant temperature, temperature deviation adjusted to within ±0.01°C), with a volume of about 100CM 3 It is carried out in a container to manufacture a mixture of multi-group ratios of chlorodifluoromethane (R22) and dimethyl ether (Dimethyl ether), and make it reach vapor-liquid equilibrium (Vapor-liquid Equilibrium). The container is equipped with a 0-5Mpa vapo...

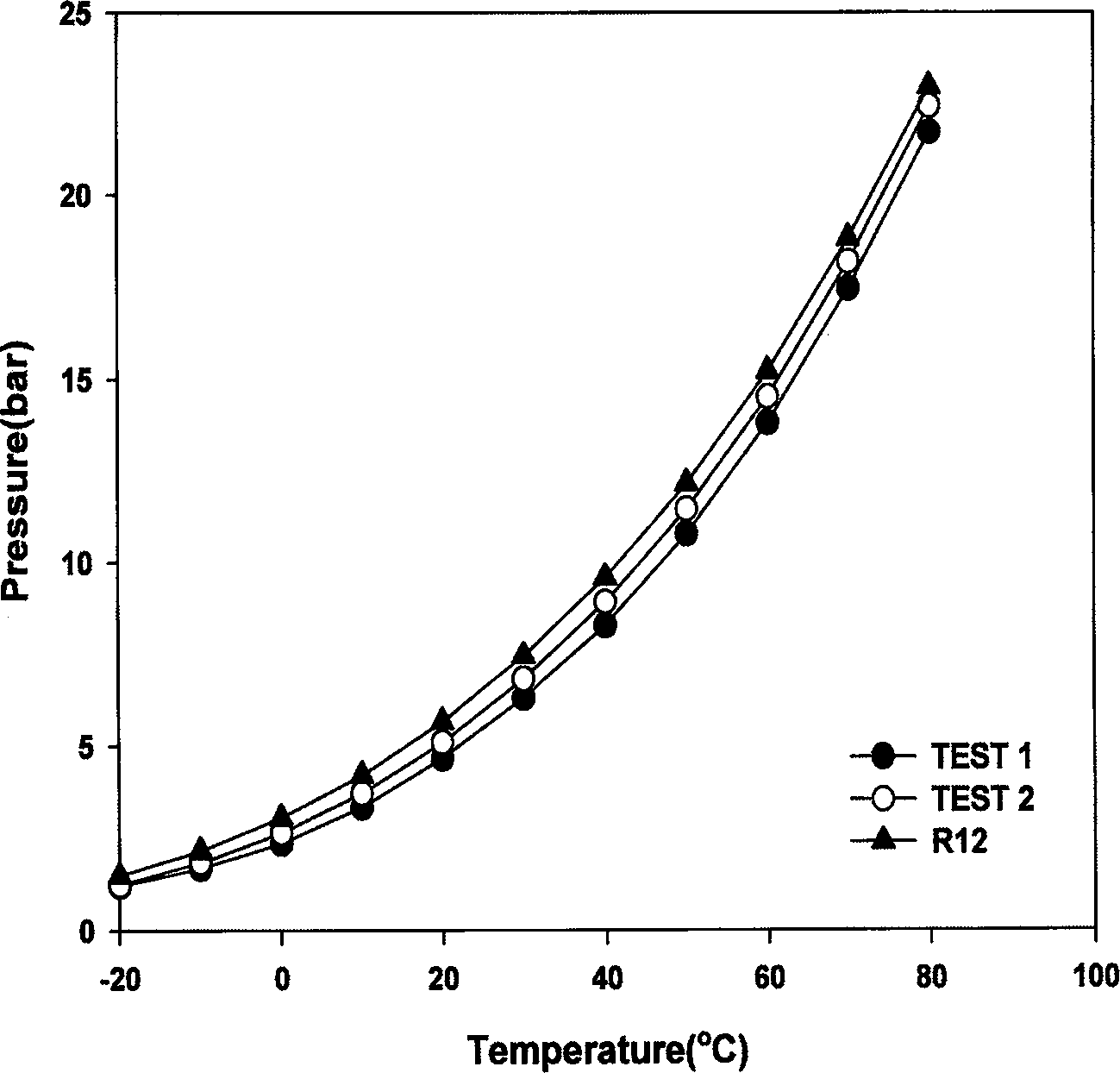

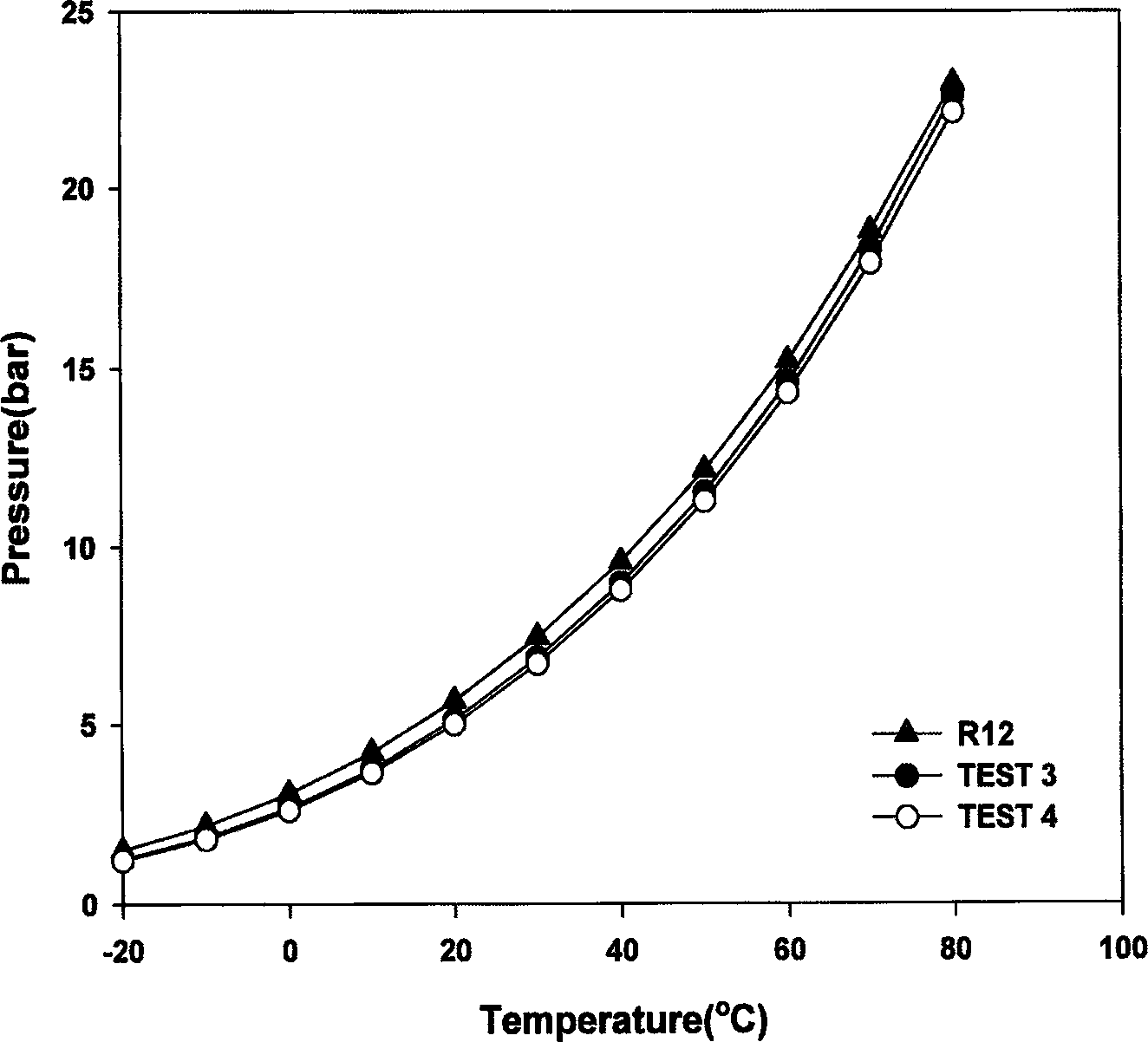

Embodiment 2

[0036] This example further demonstrates that a suitable mixture of chlorodifluoromethane (R22) and dimethyl ether (Dimethylether) exhibits azeotropic properties.

[0037] Experiment: Distillation experiment. If the mixture is non-azeotropic, the lowest boiling point in the mixture will be distilled first, and the other components in the mixture will also separate.

[0038] Instruments and equipment: the volume is about 1200CM 3 Reboiler (Reboiler) (4 m height distillation column with 39 10 cm sieves (Nit mesh), each distillation column consists of multiple 4 inch diameter condensers); vapor pressure gauge and temperature.

[0039] Experimental method: A mixture of chlorodifluoromethane (R22) and dimethylether (Dimethylether) is produced in the reboiler, the temperature of the condenser is kept constant, and a fixed amount of heat is added to the reboiler (reboiler) to achieve thermodynamic equilibrium After the state, the liquid sample was taken in the reboiler and analyzed...

Embodiment 3

[0046] This example demonstrates the miscibility of a mixture of chlorodifluoromethane (R22) and dimethyl ether with antifreeze oil used in compressors.

[0047] Use 150CM 3 The wall of the measuring cup is tempered glass, inject 10ml of antifreeze oil, and then inject about 20g of dimethyl ether (Dimethyl ether). After mixing with a magnetic drive stirrer, continue injecting chlorodifluoromethane (R22) to confirm whether it is separated from the oil The method of miscibility experiment was carried out.

[0048] The temperature was maintained at 25°, and the injection amount of chlorodifluoromethane (R22) was gradually increased to 80g to confirm its state. In order to prevent abnormalities, the change was continuously observed for the next 168 hours.

[0049] The oils used in the above experiments were mineral oil (SUNISO, 5GS) used in HCFC refrigerants and ester-based synthetic oils (OM Master, OM-PAG) used in HFC refrigerants.

[0050] The test results are shown in Table ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com