Connecting tube in use for drinking water apparatus

A technology for connecting pipes and water dispensers, which is applied in the direction of pipes/pipe joints/fittings, hoses, pipes, etc., which can solve the problems of easy aging, high product cost, and poisonous silicone tubes, and achieve the effect of overcoming easy detachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

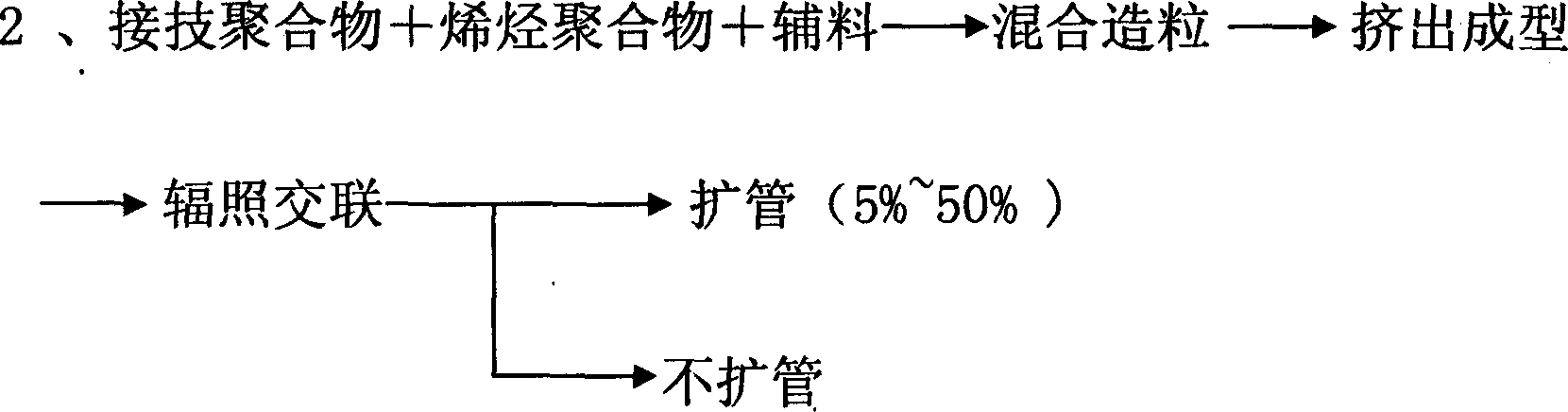

Method used

Image

Examples

Embodiment 1

[0024] Using acrylic acid butyl polymer and high-pressure polyethylene in a ratio of 1:9, through a mixing and granulation process, a granular product is made, and then extruded through a single-screw extruder to obtain a tube with an inner diameter of 12MM and a wall. A rubber hose with a thickness of 1.5MM, the rubber hose undergoes the above-mentioned electron irradiation process, and the radiation cross-linking reaction is carried out with a dose of 8 MeV. The rubber hose passes through the irradiation device at a constant speed of 8 m / s, and the irradiated product passes through After the tube is expanded and formed, a rubber tube with a tube expansion ratio of 10% is finally produced.

Embodiment 2

[0026] Using anhydride-grafted polyethylene and ethylene-vinyl acetate copolymer, after the above mixing and granulation process, the granule product is then extruded by a single-screw extruder to produce a rubber hose with an inner diameter of 12MM and a wall thickness of 1.5MM. After the above-mentioned electron irradiation process, the rubber hose is carried out with a dose of 4 MeV, and the irradiation cross-linking reaction is carried out. The rubber hose passes through the irradiation device at a constant speed of 8 m / s, and the irradiated product is finally obtained by expanding the tube. Rubber hose with 10% expansion ratio.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com