Comprehensive test instrument for performance of acoustic material

A comprehensive tester and acoustic material technology, applied in scientific instruments, analytical materials, and material analysis using sound waves/ultrasonic waves/infrasonic waves, etc., can solve problems such as low test efficiency, complex data processing process, and accuracy dependence, and improve the market. Competitiveness and enterprise benefits, broad application prospects, fast debugging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

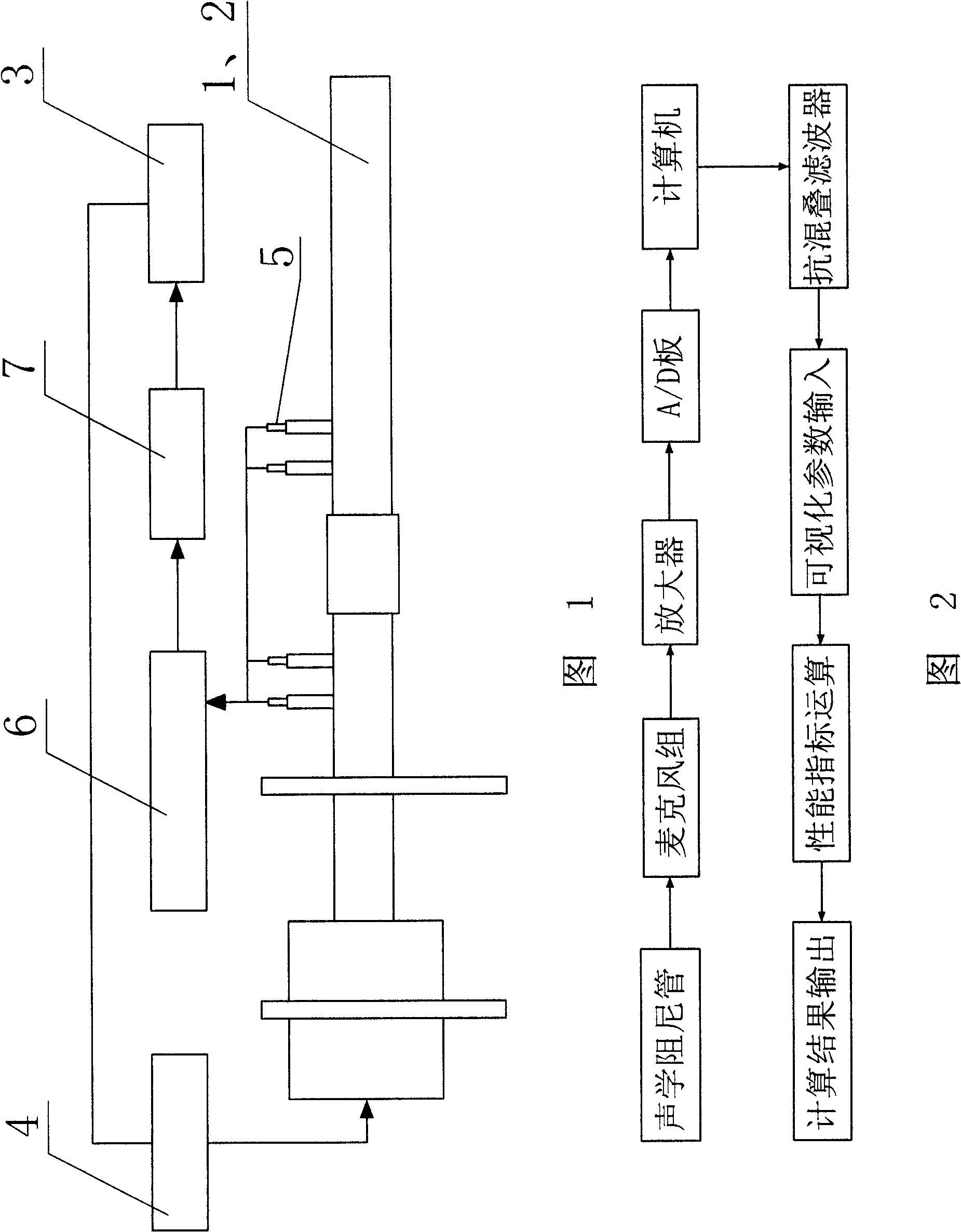

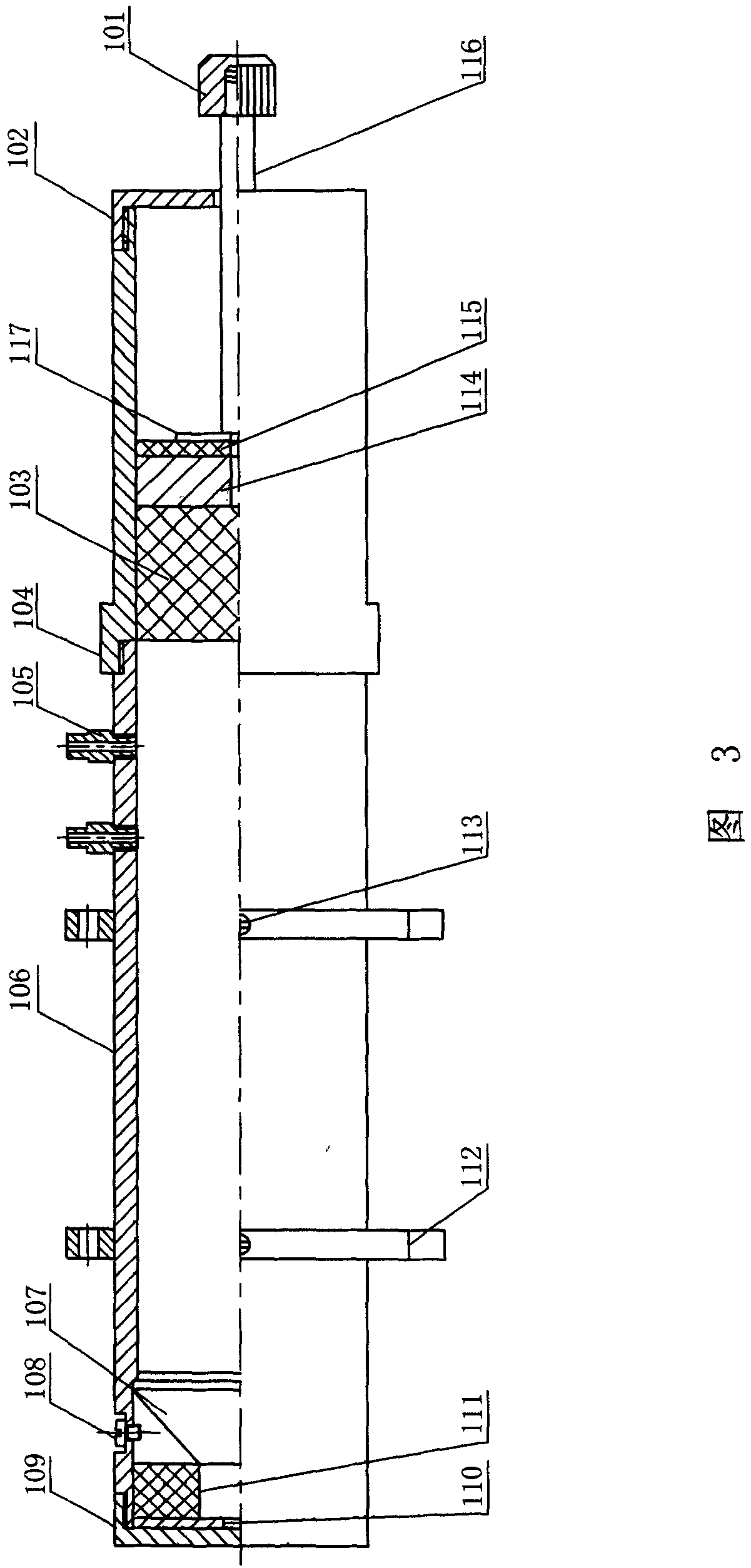

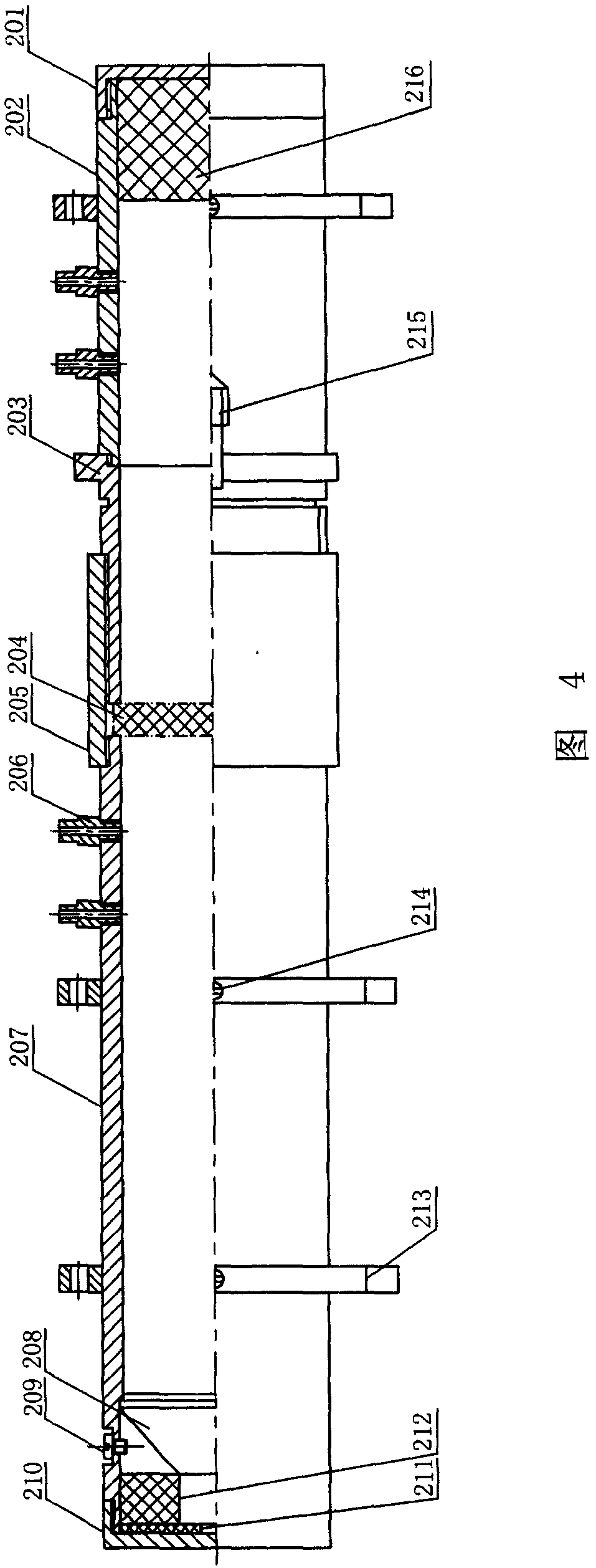

[0016] Such as Figure 1 ~ Figure 4 As shown, the acoustic material performance comprehensive tester is composed of a computer 3 for processing collected data, a double-microphone standing wave tube 1 , a four-microphone standing wave tube 2 , and a four-microphone group 5 . Described double microphone standing wave tube 1 is by the first front standing wave tube 106 and the first rear standing wave tube 104 that are connected by thread, the first front end cover 109 that is installed on the first front standing wave tube 106, is located at The first loudspeaker 107 and the BNC interface 108 at the front of the first standing wave tube 106, the first front pad 110 and the first ring pad 111 placed between the first front end cover 109 and the first loudspeaker 107, are installed on Two first microphone clamps 105 at the rear of the first front standing wave tube 106, the piston rod support cover 102 installed at the rear end of the first rear standing wave tube 106, pass throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com