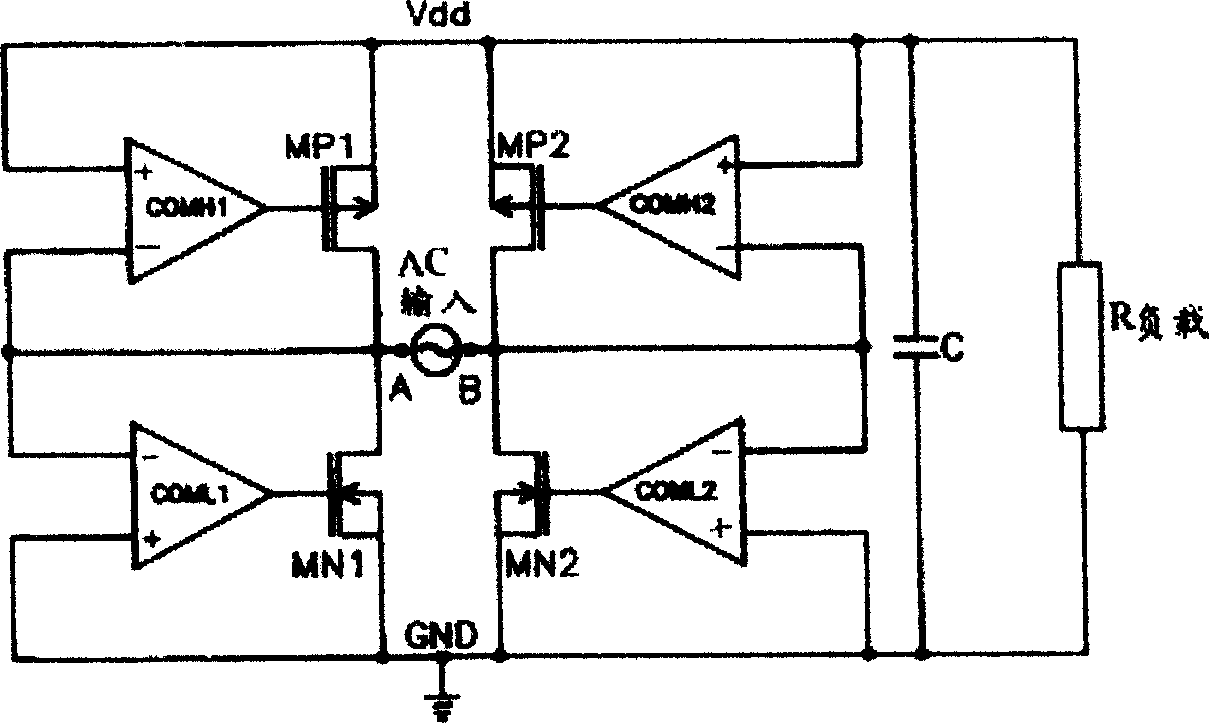

Full wave bridge type circuit of synchronous rectification

A technology for synchronous rectification and shaping circuits, which is applied in the direction of electrical components, AC power input conversion to DC power output, output power conversion devices, etc., and can solve problems such as circuits that cannot work independently, complicated circuit operations, and complicated circuit structures. To achieve the effect of expanding the use range, temperature rise and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific working process of the embodiment of the present invention will be further described below in conjunction with the accompanying drawings.

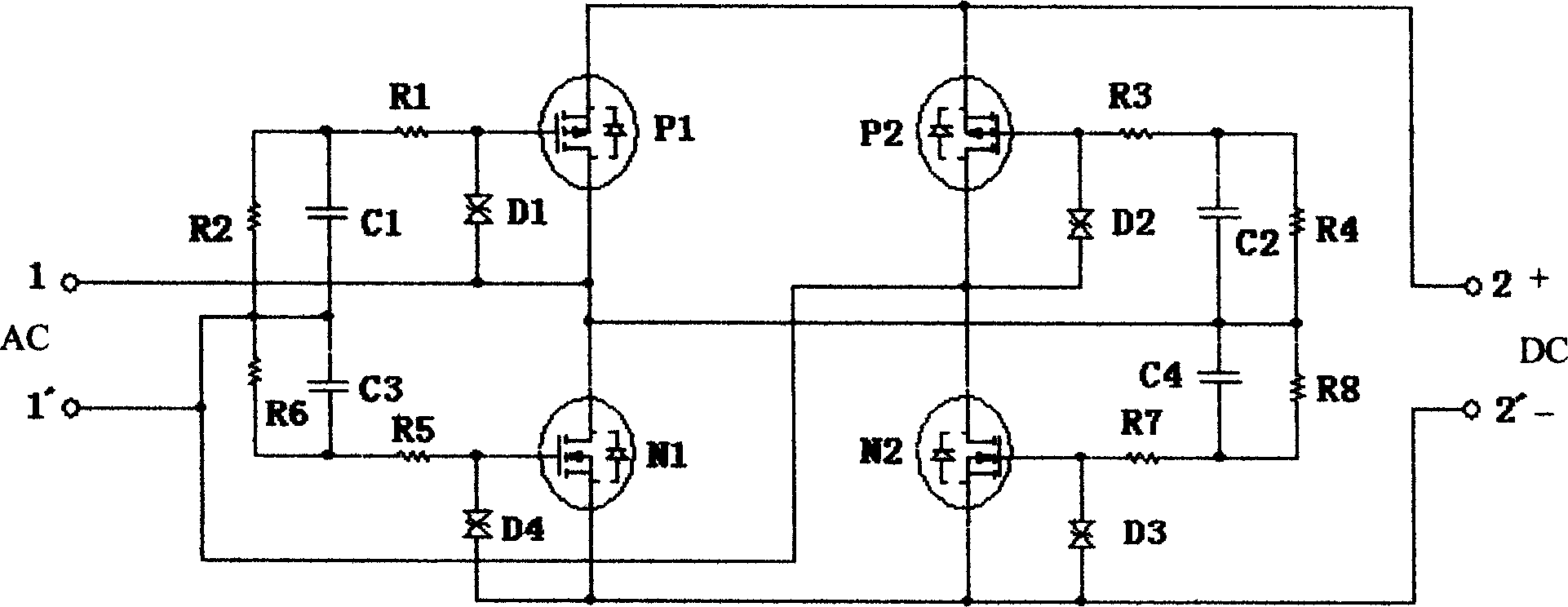

[0020] Such as image 3 As shown, the full-wave bridge synchronous rectification circuit is composed of four MOSFETs, two of which are NMOSFET tubes N1 and N2, two of which are PMOSFET tubes P1 and P2, and: two special-shaped tubes N1 and P1 The drain is electrically connected to the 1 terminal of the AC input voltage; the drains of the two special-shaped tubes N2 and P2 are electrically connected to the 1' terminal of the AC input voltage; the sources of the two same-shaped tubes N1 and N2 are electrically connected to the DC output voltage terminal 2 of the same type tubes; the sources of the two tubes P1 and P2 are electrically connected to the terminal 2' of the DC output voltage. Bidirectional Zener Diode D 1 Connected between the gate and source of PMOS transistor P1; bidirectional voltage regulator diode D 2 C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com