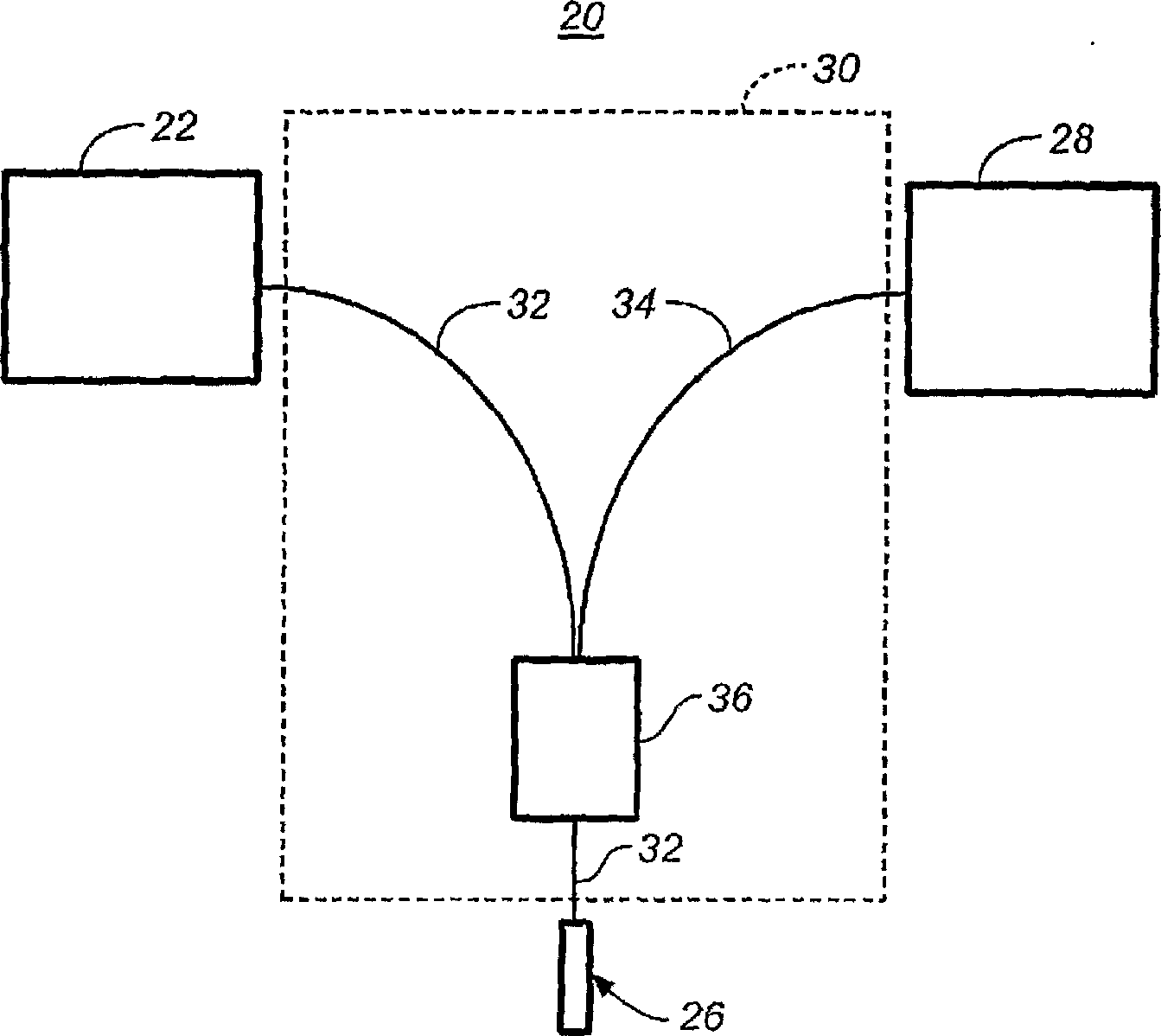

Fiber-optic assay apparatus based on phase-shift interferometry

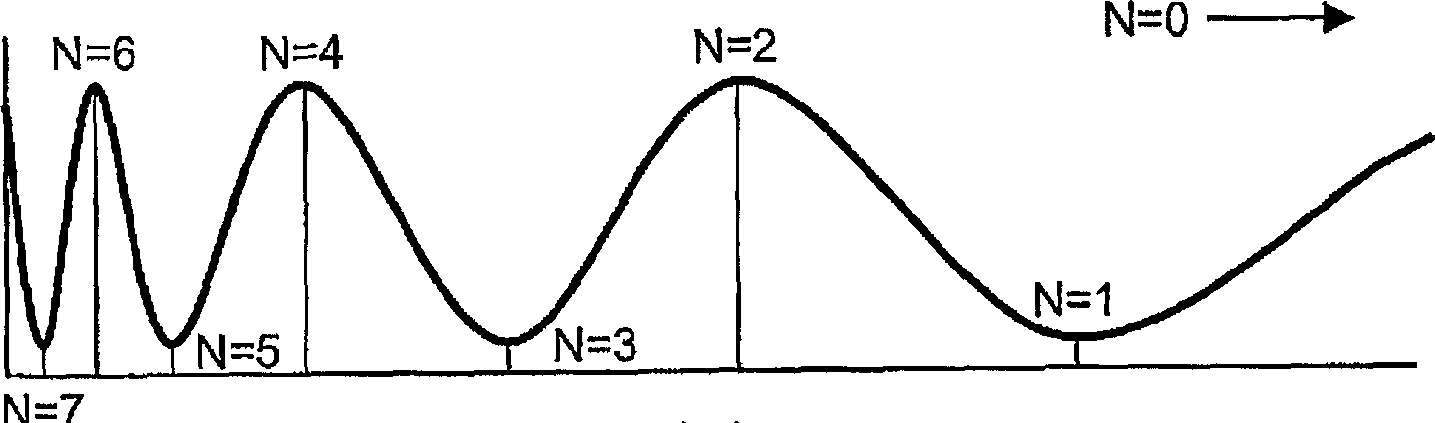

An optical fiber and analyte technology, applied in the field of devices based on optical fiber interferometry, can solve the problem of no easily identifiable wavelength spectrum extremes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

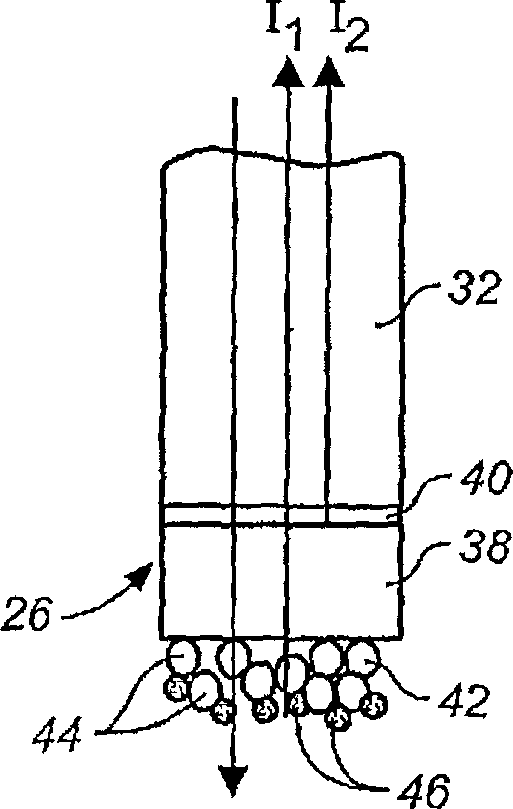

[0099] Example 1: Small molecule-protein binding reactions.

[0100] This example was used to demonstrate the ability to detect protein binding to a small molecule immobilized on the sensor tip and subsequently to multiple antibodies. This test uses a double-layer structure at the fiber tip. First Ta 2 o 5 layer thickness is 25nm and the second SiO 2 The thickness of the layer is 770 nm. Optical fibers were purchased from Ocean Optics (Dunedin, Florida). It was manually cut into 40 mm long segments. Both ends of the segments are polished to standard mirror quality. The polishing methods used here are exactly the same as those used for optical lenses and mirrors. One surface of the fiber segments is supplied to an optical coating chamber to coat Ta 2 o 5 layer and SiO 2 layer. This supplier uses an ion beam assisted physical vapor deposition (IAPVD) coater manufactured by Leybold. IAPVD is a coating technique commonly used for anti-reflection and optical filters. T...

example 2

[0106] Example 2: Biomolecular interaction analysis of biomolecular interaction kinetics and affinity.

[0107] This example illustrates the implementation of the present invention for biomolecular interaction analysis (BIA) for determining the kinetics and affinities of biomolecular interactions. The same tip configuration as described in Example 1 was used. This experimental procedure included the following (unless otherwise stated, steps used were performed at room temperature):

[0108] Prepare mercaptosilane-coated tips using the following procedure. Clean and dry fibers were incubated in toluene:caproic acid:mercaptopropyltrioxysilane (10:2:1 volume ratio) at room temperature for 24 hours. The optical fibers were rinsed twice with 10 ml of toluene for 5 minutes each time. The fibers were then rinsed once with 10 mL of ethanol and dried under argon flow and stored under ambient conditions.

[0109] Biosensor tips were first obtained by dipping for 1 hour with 10 μg / ml...

example 3

[0114] Example 3: Calculation of affinity constants from antibody-antigen binding and release curves.

[0115] This experiment demonstrates the calculation of affinity constants by measuring the association and dissociation curves of two antibodies with their antigens. These specific antibodies were labeled Ab-1 and Ab-2. The molecular weight of this antigen is about 30 kilodaltons. The same tip configuration as in Example 1 was used. The same mercaptosilane optical fiber preparation as in Example 2 was used. The experimental procedures are described as follows (unless otherwise stated, the steps used were carried out at room temperature):

[0116] This fiber optic tip is activated for covalent attachment of the antigen. Mercaptosilane-coated optical fibers were prepared by dipping the sensor tip in 50 μL of 50 mg / mL sulfo-SMCC (Pierce Biotechnology, Rockford EL; Cat. No. 22322) in DMF (Sigma-Aldrich Chemical Company, St Louis, MO; Cat. No. 494488). solution for 2 hours t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com