Method for fabricating nickel zinc ferrite integrated with PIN and dedicated smelting tool therefor

A technology of nickel-zinc ferrite and manufacturing method, which is applied in the direction of inductance/transformer/magnet manufacturing, electrical components, circuits, etc., and can solve problems such as unsatisfactory results, insufficient pins, and insufficient pulling force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] This product is manufactured using the following steps: First, glue is applied to the pin hole of the nickel-zinc ferrite core; then the PIN pin is inserted into the pin hole of the nickel-zinc ferrite core to make a nickel-zinc ferrite Connect the PIN semi-finished product; put the semi-finished product into a jig and put it into the drying device together, so that the semi-finished product is kept tilted in such a way that the position of the nickel-zinc ferrite core is lower than the PIN pin, and the temperature generated by the drying device is generated in a constant temperature. Tiny vibrations shake the product, making glue, PIN pins and ferrite cores bond together.

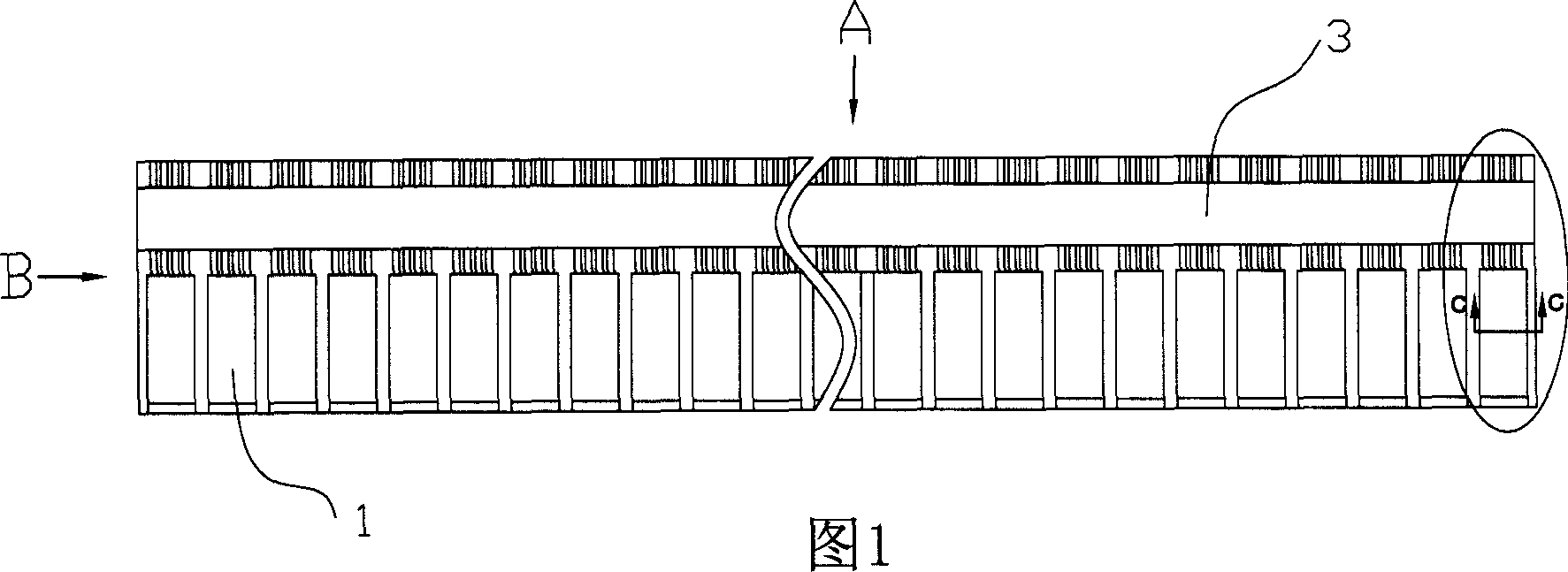

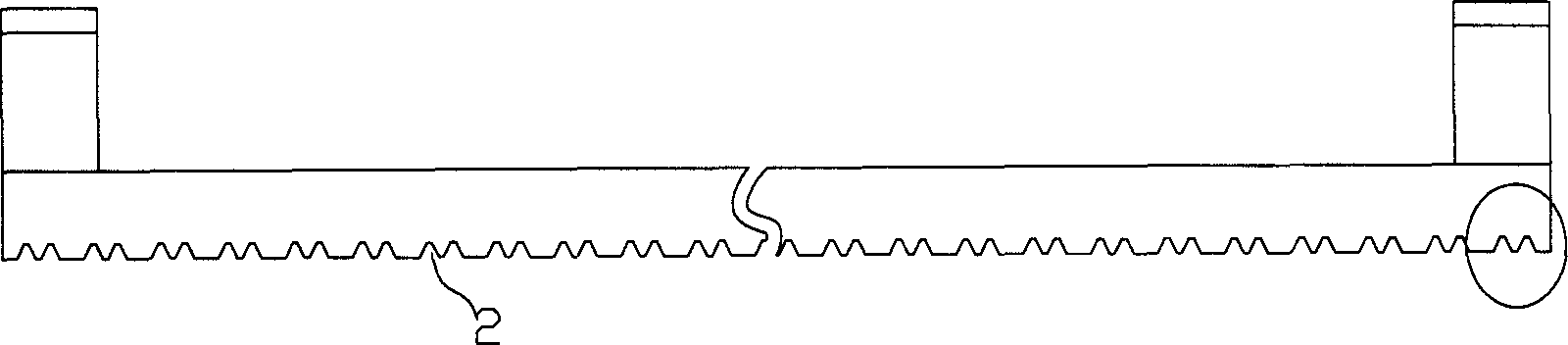

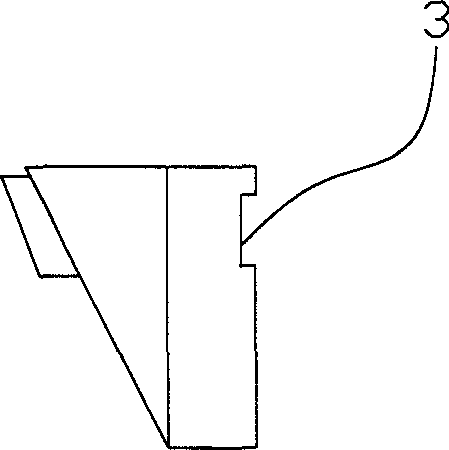

[0024] If the customer has special requirements for the height of the glue, the height of the glue can be controlled by means of dispensing equipment to meet the consistency of the glue volume of the products produced. The jig is made of heat-resistant high-temperature material. Its shape and struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com