Dehydration drying device for washing machine and dehydration drying machine

A clothes drying device and technology of clothes dryer, which are applied in the directions of household clothes dryers, washing devices, other washing machines, etc., can solve the problems of high cost, low efficiency, complicated structure and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

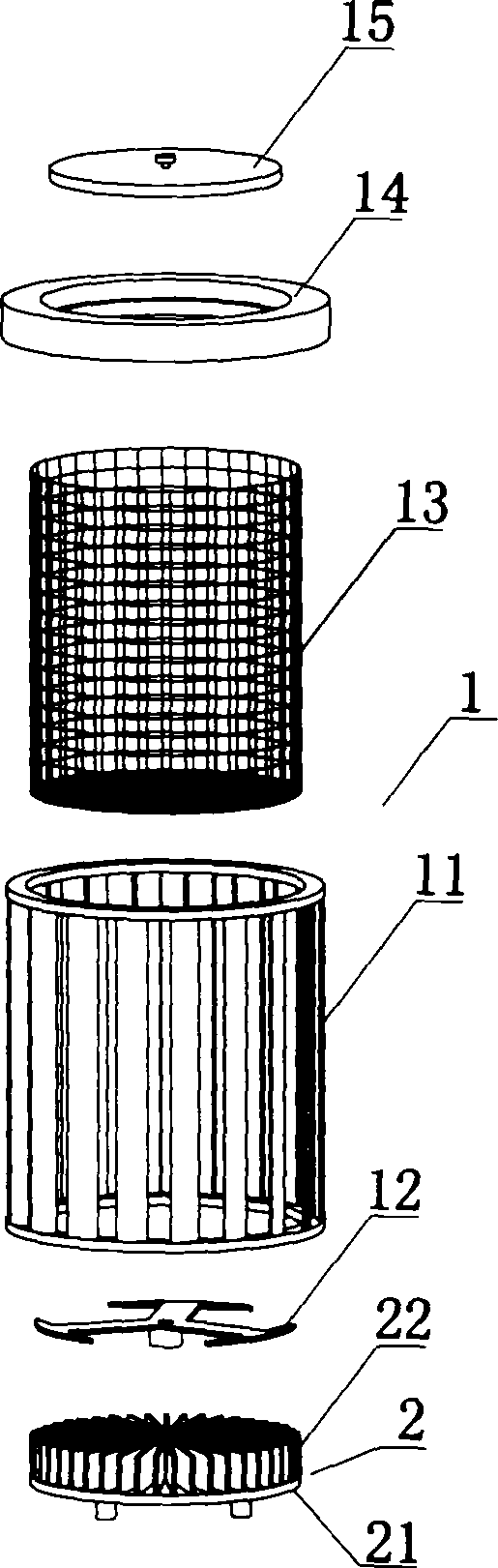

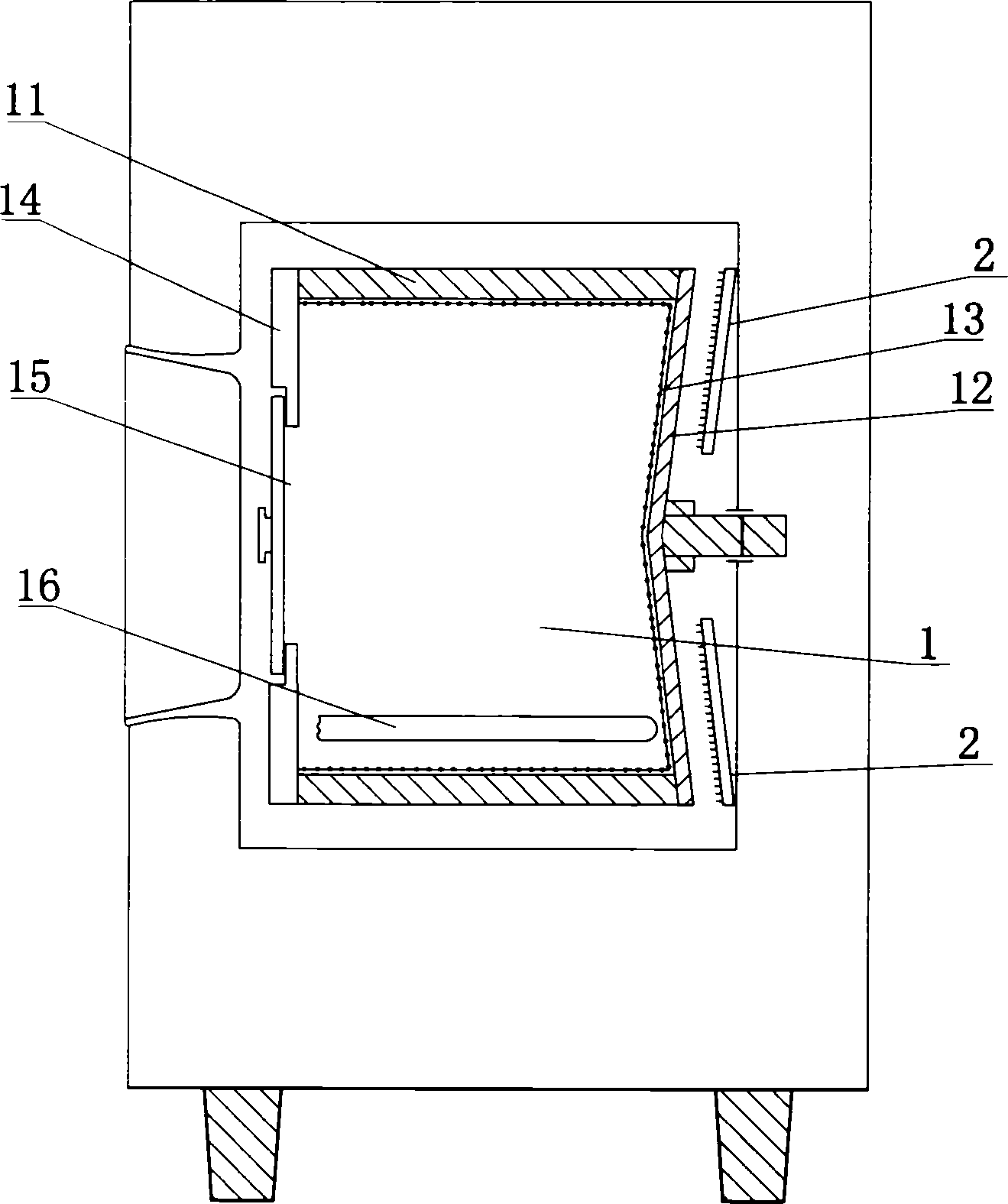

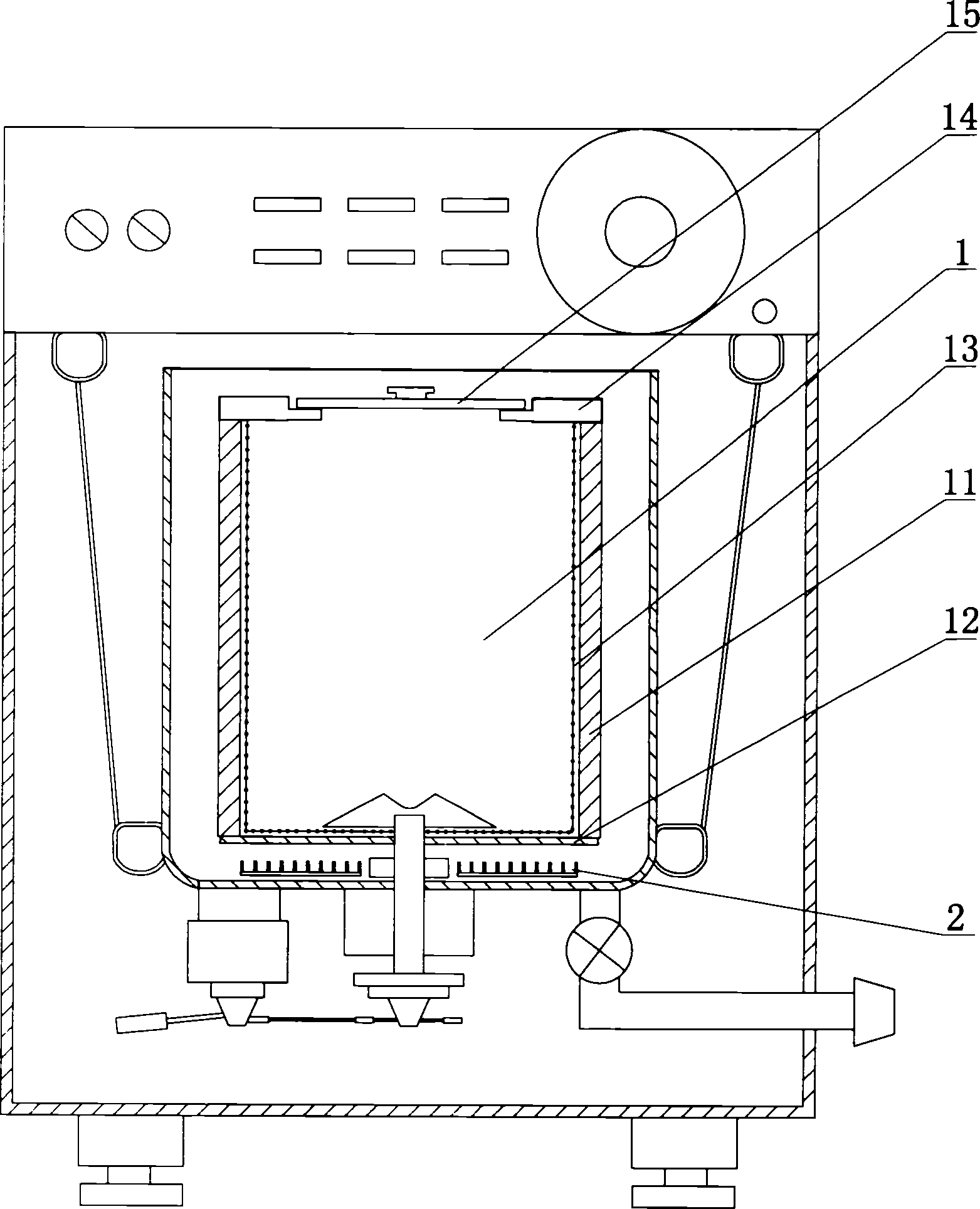

[0014] Such as Figure 1 ~ Figure 3 As shown, the dehydration and drying device for washing machines and dehydration dryers according to the present invention includes a dehydration bucket 1 that is rotatably installed in the bucket of the washing machine or dehydration dryer, and is installed at the bottom of the dehydration bucket. 1 and the heating element 2 connected to the electrical control part of the washing machine or dehydration dryer between the tub, and a ventilated and drainable gap is formed between the outer wall of the dehydration tub 1 and the inner wall of the tub, wherein the dehydration tub The barrel 1 includes a centrifugal fan impeller-type barrel body 11 surrounded by several blades, a barrel body 11 for supporting and driving the barrel body 11 to rotate at high speed and connected to the power output device of the washing machine or dehydration dryer, which is composed of several poles. A bucket bottom 12 with at least two ventilation openings that ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com