Primacord rolling method and primacord rolling machine

A technology of detonating cord and rolling mill, which is applied in the direction of metal rolling, metal rolling, rolling, etc., can solve the problems of no detonating cord, safety problems, large resistance, etc., and achieve a good market competitive advantage and uniform charge density , the effect of small temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

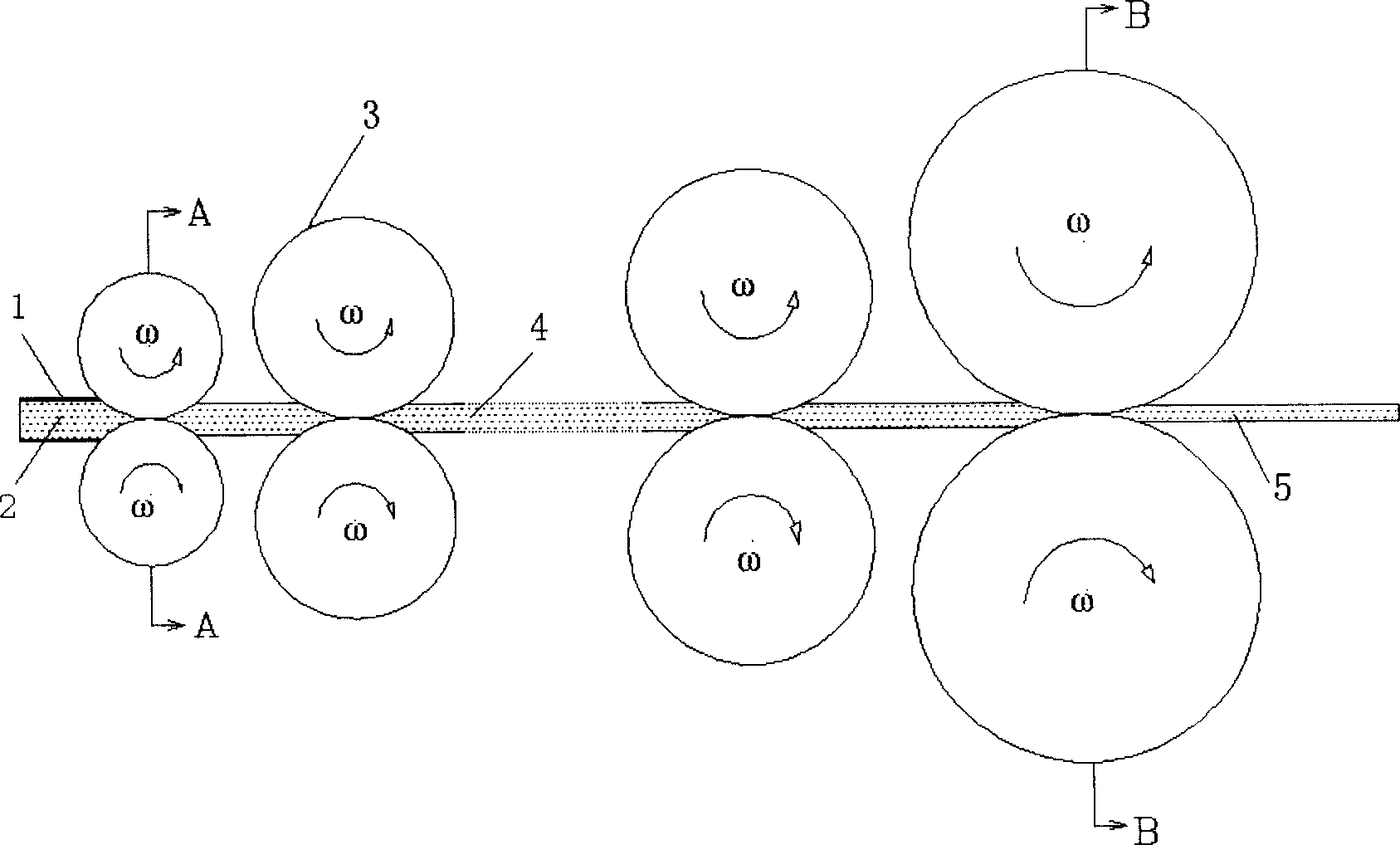

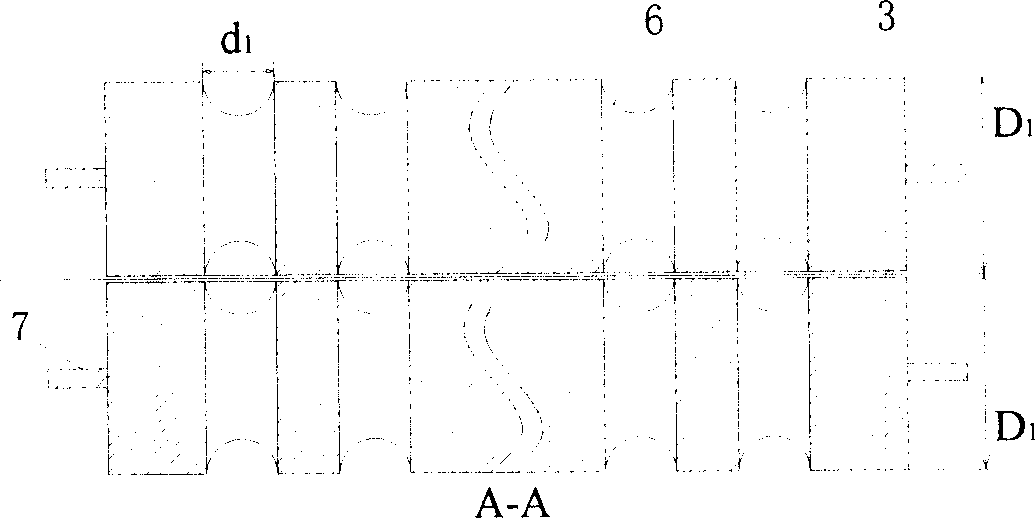

[0022] Embodiment 1: Rolling lead skin detonating cord with variable diameter roll mill

[0023] In this embodiment, a lead pipe with an inner diameter of 16 mm and an outer diameter of 20 mm is used as the charge blank tube of the passivated explosive.

[0024] Determination of the mass ratio and density of passivated explosives: Because RDX has high viscosity and poor fluidity, it is necessary to add binders to change its physical state, enhance fluidity for easy operation and processing, and at the same time ensure stable detonation. After a large number of experiments, it is advisable to select a mass ratio of 90-98% of RDX and 10-2% of the binder, fully bond and mix evenly in a bowl, and use the prepared passivated explosive From the open end downward, according to the volume and packing density of the blank tube, it is 0.6-1.0g / cm 3 According to the requirements within the range, weigh the passivated explosives, quantitatively load them into the blank tube, keep the cha...

Embodiment 2

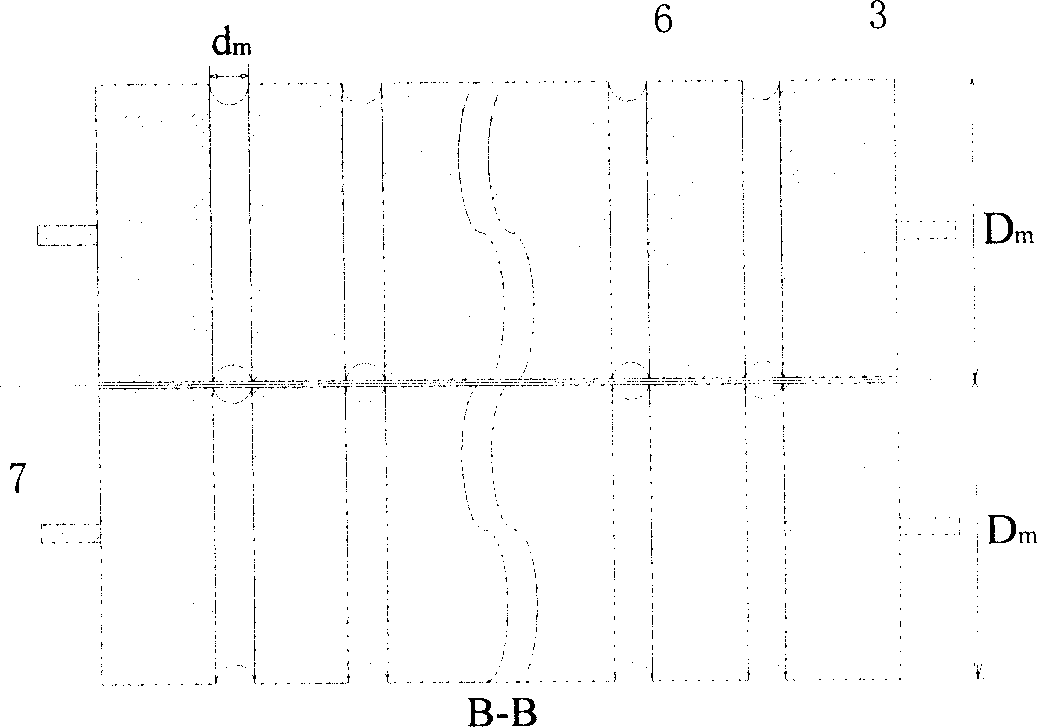

[0055] Embodiment 2: Rolling high-pressure polyethylene plastic detonating cord by variable-diameter roll rolling machine

[0056] When the soft blank tube adopts a non-metallic tube, explosives can be continuously loaded into the thick tube during the tube forming process of the non-metallic tube; when the blank tube is made of plastic or heat-deformable material, it is necessary to heat the source and heat preservation in the process measure.

[0057] In this embodiment, a high-pressure polyethylene plastic pipe with an inner diameter of 10 mm and an outer diameter of 14 mm is used as the charge blank pipe of the passivated explosive. The high security high explosive is packed in the prefabricated thick tube.

[0058] The specific steps of this embodiment are as follows:

[0059] Dispensing: the mass ratio is 98% of RDX and 2% of binder;

[0060] Charge: One end of the polyethylene plastic billet tube is closed and the other end is open, and the passivation explosive is q...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com